Thermoplastic elastomer, preparation method and use thereof

A thermoplastic elastomer and modification technology, applied in the field of thermoplastic elastomer and its preparation, can solve the problems of poor weather resistance, chemical corrosion resistance, poor weather resistance, easy migration of processing oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

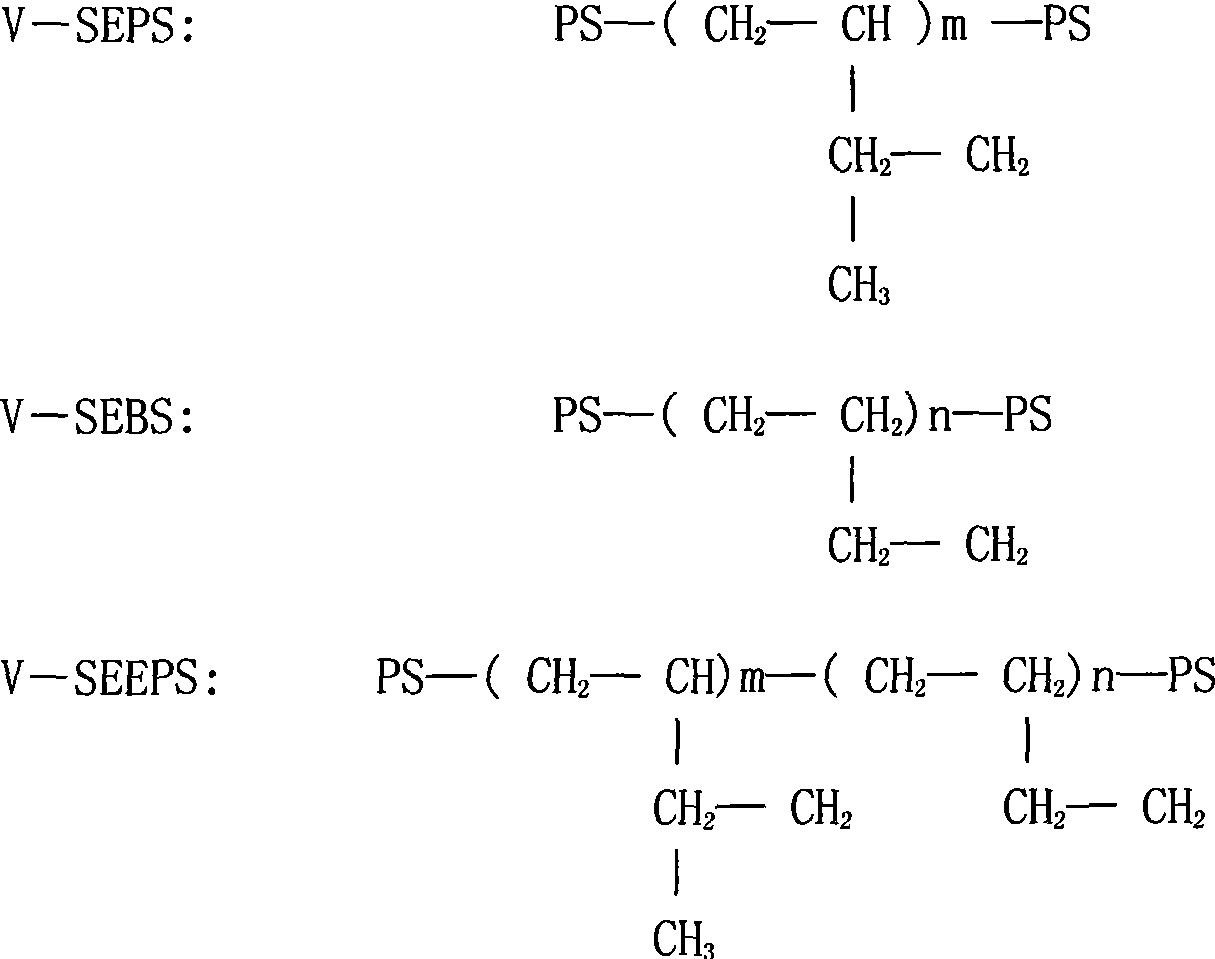

Method used

Image

Examples

Embodiment 1

[0055] The following components are represented by product models, and each product model has been described in detail in the content of the invention.

[0056] The thermoplastic elastomer comprises the following components in total weight percent:

[0057] A. RP-346R 10

[0058] B. HYBRAR TM 7311K 45

[0059] C. VERSIFY TM 3401 45

[0060] Provide a mixture of the above components, and use a twin-screw extruder to knead and granulate the mixture. The twin-screw extruder is produced by Berstorff, Germany, model ZE25A. The process conditions are: melt temperature 190-220 °C, screw speed 100-450rpm, head temperature 180-200°C, screw feeding section temperature 160-180°C, screw melting section temperature 180-220°C, to obtain a thermoplastic elastomer.

Embodiment 2

[0062] The thermoplastic elastomer comprises the following components in total weight percent:

[0063] A. RP-346R 10

[0064] B. Kraton MD6945 22.5

[0065] B. HYBRAR TM 7311K 22.5

[0066] C. VERSIFY TM 3401 45

[0067] The thermoplastic elastomer preparation process is the same as in Example 1.

Embodiment 3

[0069] The thermoplastic elastomer comprises the following components in total weight percent:

[0070] A. RP-346R 10

[0071] B. HYBRAR TM 7311K 45

[0072] C. VERSIFY TM 3401 22.5

[0073] C. VERSIFY TM 2400 22.5

[0074] The thermoplastic elastomer preparation process is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com