Method for preparing graphite-based Si@C negative electrode material by taking silica fume as Si source

A technology of anode material and micro-silica fume, which is applied in the field of preparing graphite-based Si@C anode materials, can solve the problems of no significant increase in theoretical specific capacity, low Si packing density, and complicated preparation process, etc. The effect of embedding depth, simple preparation process, and shortened diffusion distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

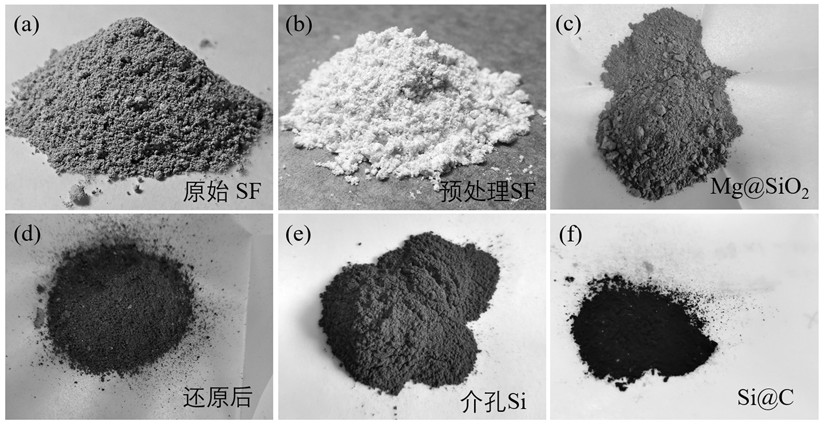

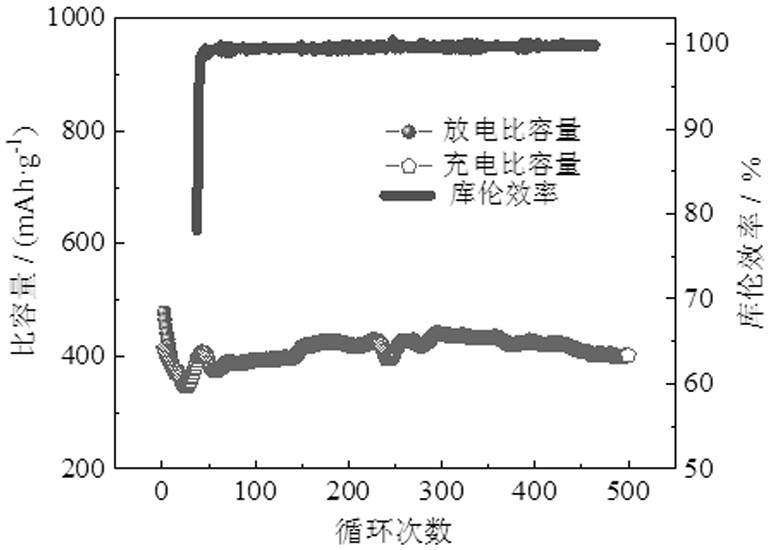

[0026] A method for preparing a graphite-based Si@C negative electrode material using microsilica powder as a Si source, specifically comprising the following steps:

[0027] (1) Raise the original micro-silicon powder in a muffle furnace at a rate of 3°C / min to 700°C for 4 hours, then disperse it in a HCl solution with a concentration of 3.26mol / L, heat it in a water bath at 60°C and stir it dynamically for 1 hour, then Raise the temperature to 90°C and stir for 4 hours, filter with suction, wash with water, and dry to obtain a pretreated sample.

[0028] (2) Mix the pretreated sample with magnesium powder with a particle size of 5 μm at a mass ratio of 1:0.85, use n-pentane as the medium, and use a planetary ball mill for mixing at a speed of 200 rpm. The ball milling time was 24 hours, and the reaction material sample was obtained after natural drying.

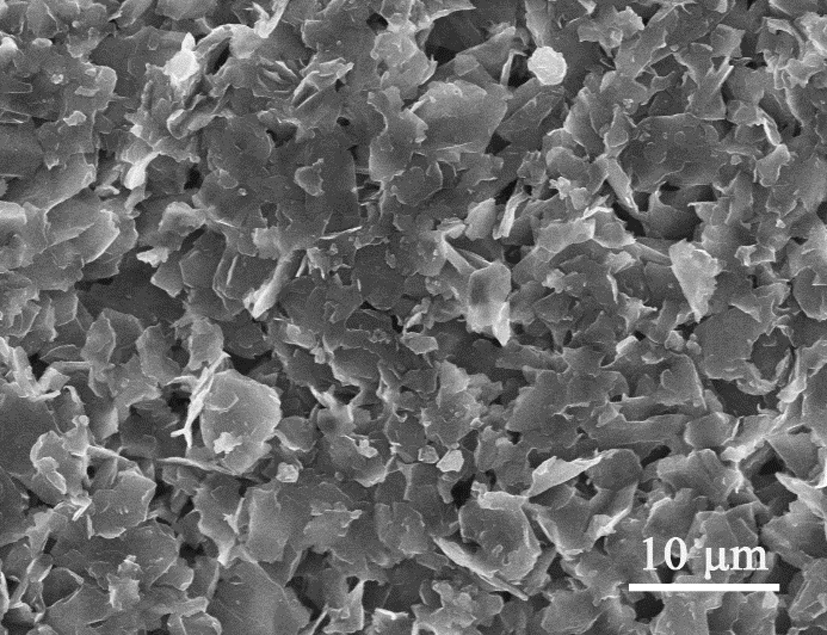

[0029] (3) Put the reaction material in a sealed graphite crucible, and in a tube furnace with Ar: increase the temperat...

Embodiment 2

[0038] A method for preparing a graphite-based Si@C negative electrode material using microsilica powder as a Si source, specifically comprising the following steps:

[0039] (1) Raise the original micro-silicon powder in a muffle furnace at 3°C / min to 600°C for 10 hours, then disperse it in an HCl solution with a concentration of 2mol / L, heat it in a water bath at 60°C and stir for 1 hour, then raise the temperature Stir at 90°C for 4 hours, filter with suction, wash with water, and dry to obtain a pretreated sample.

[0040] (2) Mix the pretreated sample and magnesium powder with a particle size of 150 μm at a mass ratio of 1:1, use n-pentane as the medium, and use a planetary ball mill for mixing at a speed of 150 rpm. The ball milling time was 48h, and the reaction material sample was obtained after natural drying.

[0041] (3) Put the reaction material in a sealed graphite crucible, and in a tube furnace with Ar: raise the temperature from room temperature to 300°C at a ...

Embodiment 3

[0046] A method for preparing a graphite-based Si@C negative electrode material using microsilica powder as a Si source, specifically comprising the following steps:

[0047] (1) Raise the original micro-silicon powder in a muffle furnace at 2°C / min to 750°C for 4 hours, then disperse it in a HCl solution with a concentration of 5mol / L, heat it in a water bath at 60°C and stir for 1 hour, then raise the temperature Stir at 90°C for 4 hours, filter with suction, wash with water, and dry to obtain a pretreated sample.

[0048] (2) Mix the pretreated sample and magnesium powder with a particle size of 100 μm at a mass ratio of 1:0.9, use n-pentane as the medium, and use a planetary ball mill for mixing at a speed of 150 rpm. The ball milling time was 24 hours, and the reaction material sample was obtained after natural drying.

[0049] (3) Put the reaction material in a sealed graphite crucible, and in a tube furnace with Ar: heat up from room temperature to 700°C at a rate of 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com