Method for on-line measuring microbe film thickness by optical fibre bragg grating sensor

A grating sensor, fiber optic Bragg technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problem of inability to measure the thickness of microbial film on-line, and achieve high stability, high refractive index sensitivity, and high resolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

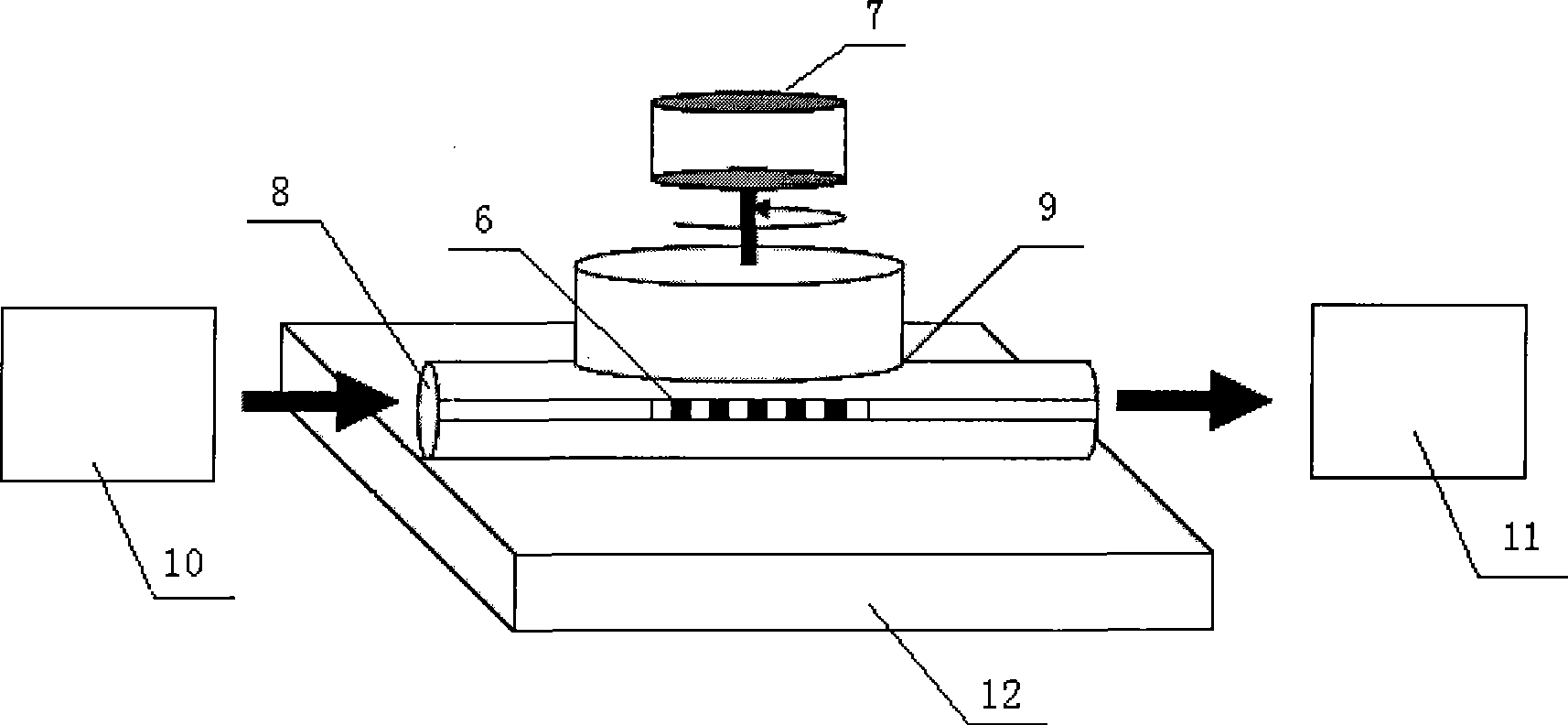

[0029] see Figure 7 , the method for online measurement of microbial film thickness by D-type fiber Bragg grating sensor is carried out as follows:

[0030] Step 1. Calibrate the microbial film thickness d and microbial film refractive index n by Abel refractometer and optical microscope 2 , so as to determine the microbial film refractive index n 2 The relationship function f(n 2 ); that is, to determine d=f(n 2 );

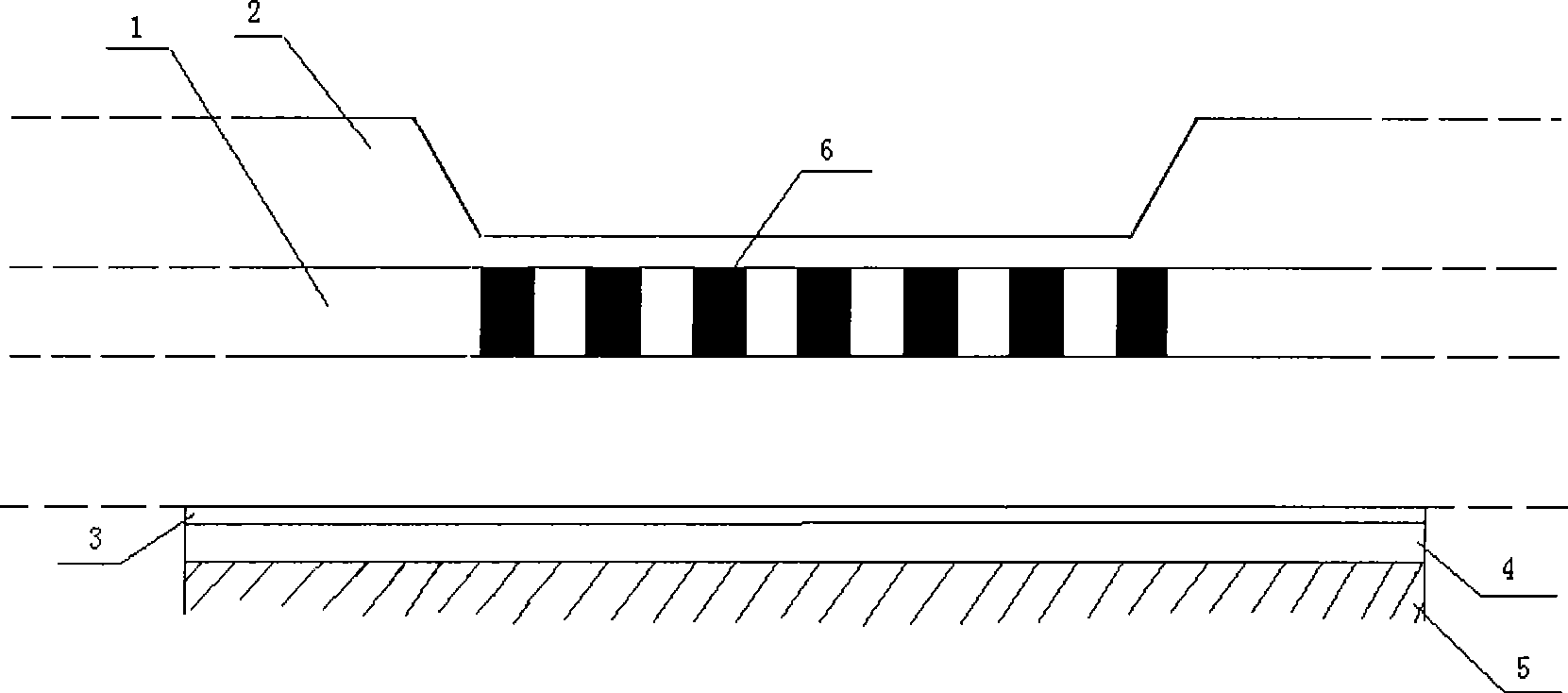

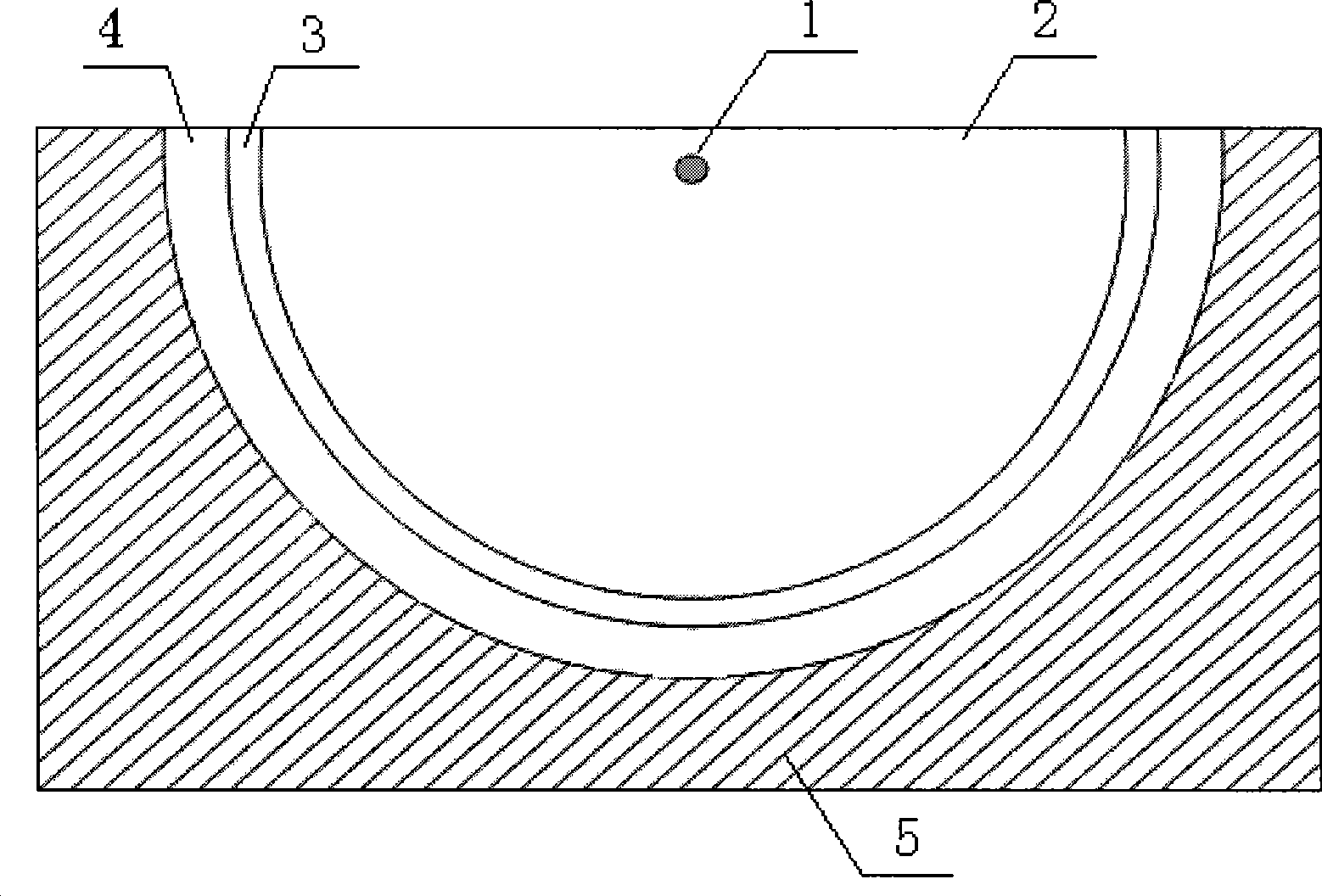

[0031]Step 2, placing a specific D-type fiber Bragg grating sensor in the biofilm trickling filter tower 18; the specific D-type fiber Bragg grating sensor is composed of a photosensitive single-mode fiber 8 and a ceramic substrate 5, wherein the photosensitive single-mode fiber 8 is composed of a core 1, a cladding 2 and a fiber coating 3. The diameter of the core 1 is about 3 μm-4 μm. At the same time, a fiber Bragg grating 6 is written in the photosensitive single-mode fiber 8. The two ends of the ceramic base 5 are respectively provided with two semicir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com