Plastic foam three-dimensional rapid forming method and device based on column coordinate

A foamed plastic, cylindrical coordinate technology, applied in the direction of instruments, computer control, simulators, etc., can solve the problems of large shape accuracy error and low forming efficiency, and achieve the effect of reducing manufacturing cost and improving machining accuracy and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

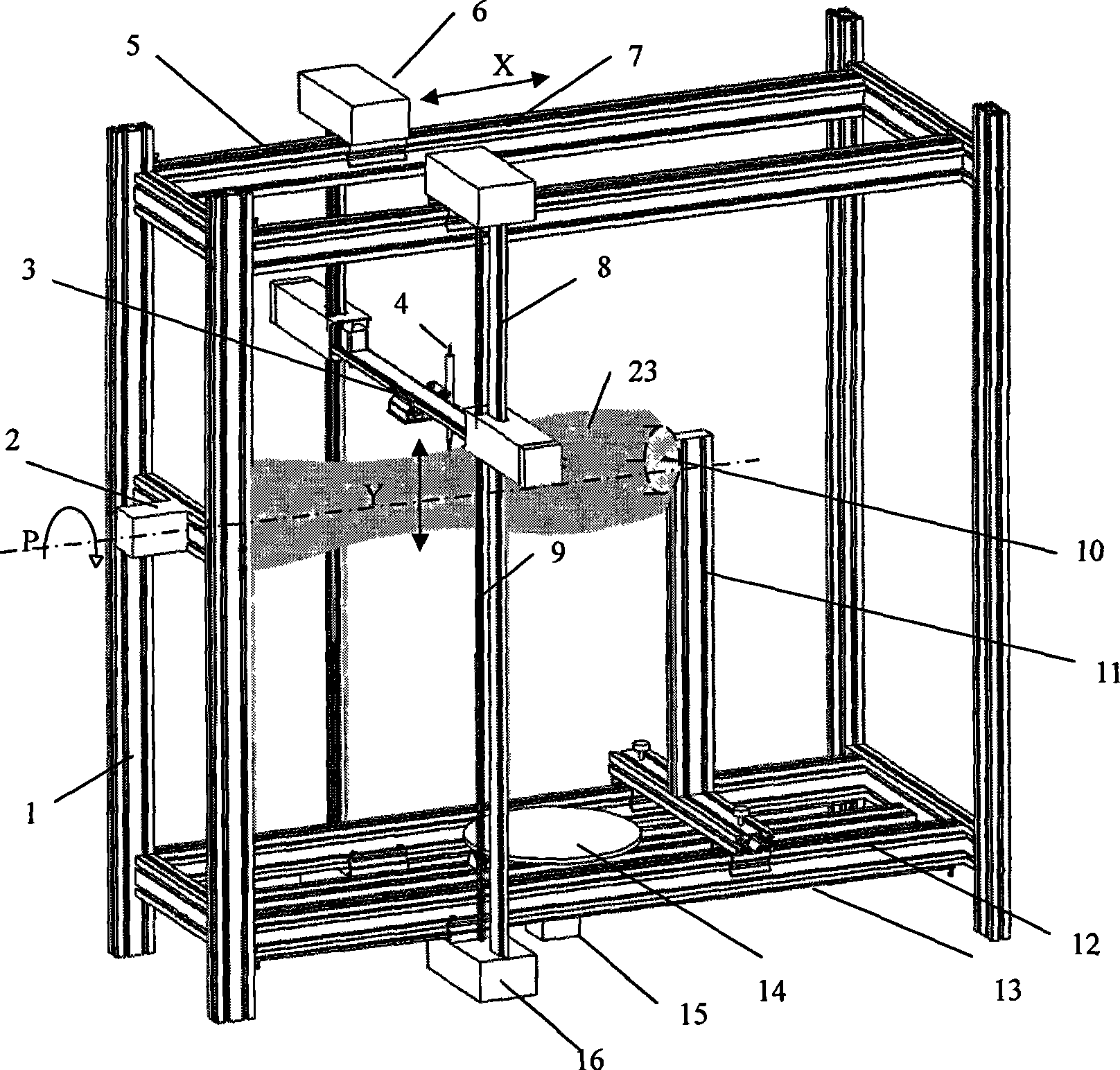

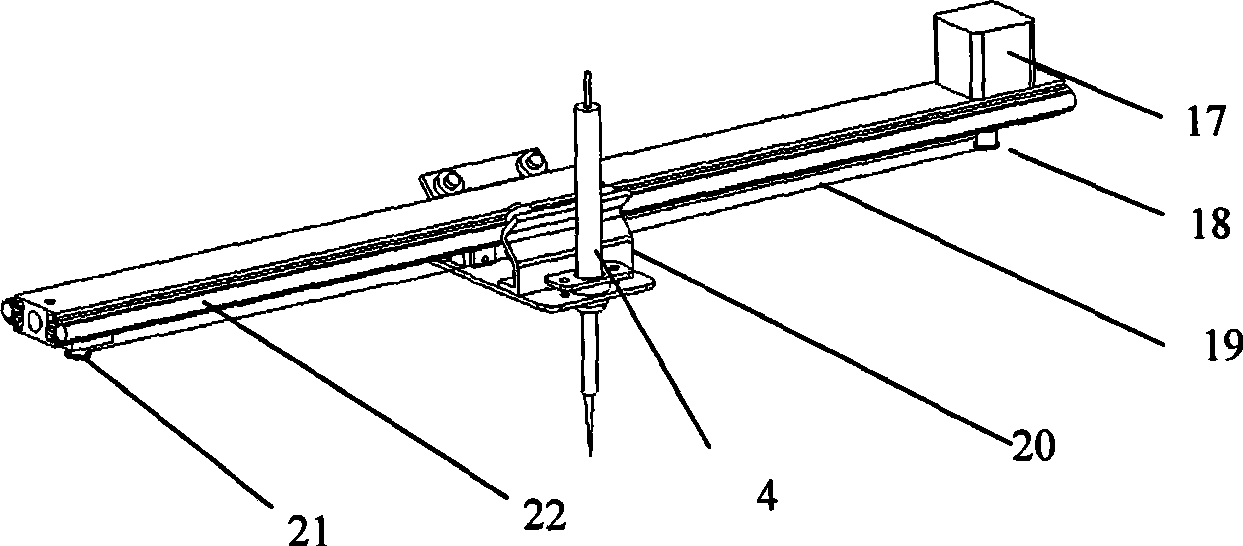

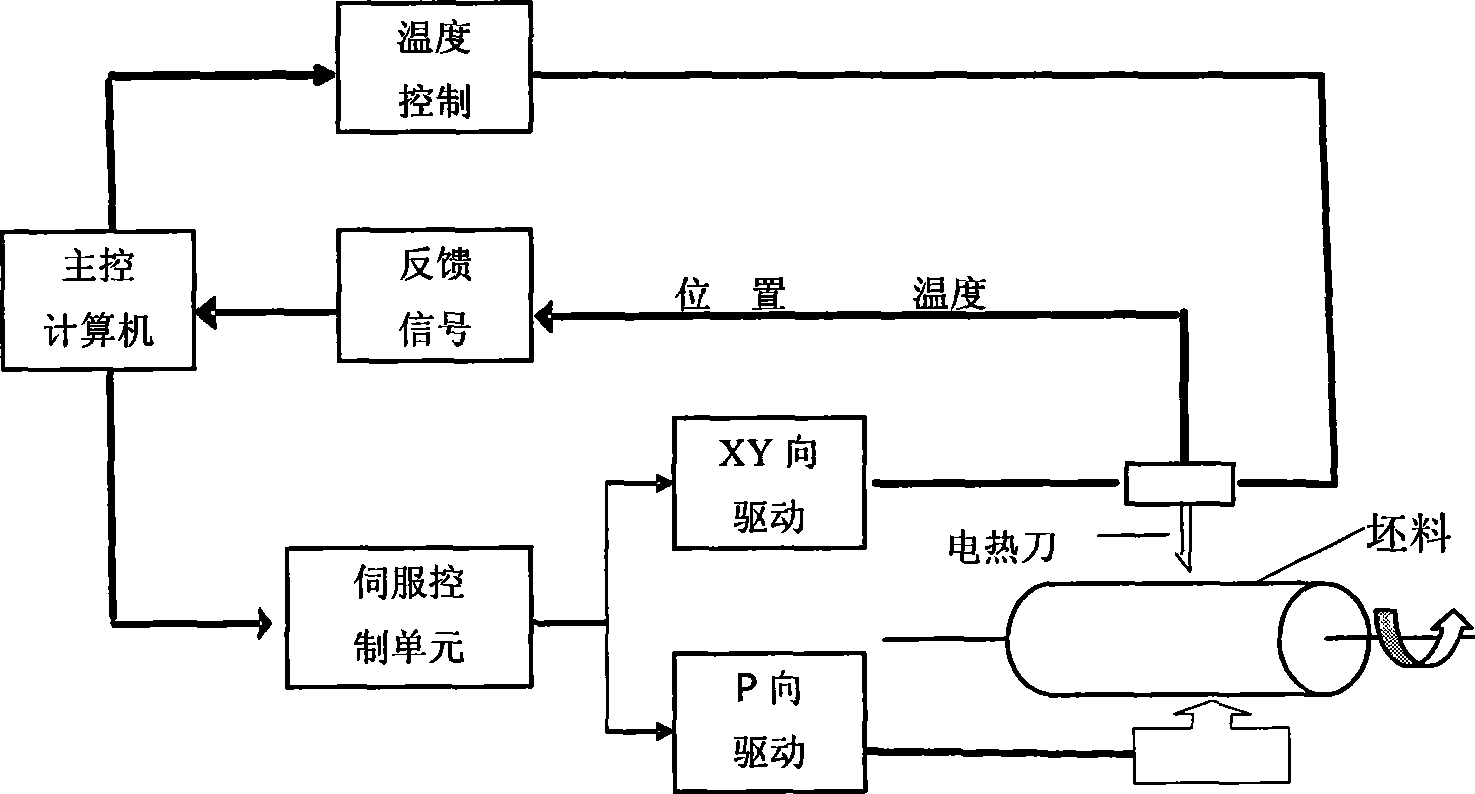

[0045] see figure 1 , figure 2 , image 3 The three-dimensional rapid prototyping equipment for foamed plastics of the present invention consists of a two-dimensional planar motion mechanism of an electric heating knife; a blank fixing and rotating mechanism; an auxiliary vertical rotating mechanism; an electric heating knife and a computer control system ( image 3 )composition.

[0046] The computer controls the two-dimensional (x, y) plane motion processing mechanism driven by six stepping motors; the rotatable blank 23 fixed mechanism driven by the rotary motor 2 realizes the rotation of the blank, and cooperates with the above-mentioned two-dimensional plane motion to form a machine controlled by the computer. The three-dimensional fixed-angle or fixed-thickness layered processing mode of the electric heating knife; the processing devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com