Reconfigurable static reactive compensation/DC deicing composite apparatus monitoring system

A technology of static reactive power compensation and monitoring system, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problem of no such device application, achieve consistency, simple device operation, and avoid misoperation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: The working mode of the composite device is restructured into the mode of the static var compensation device

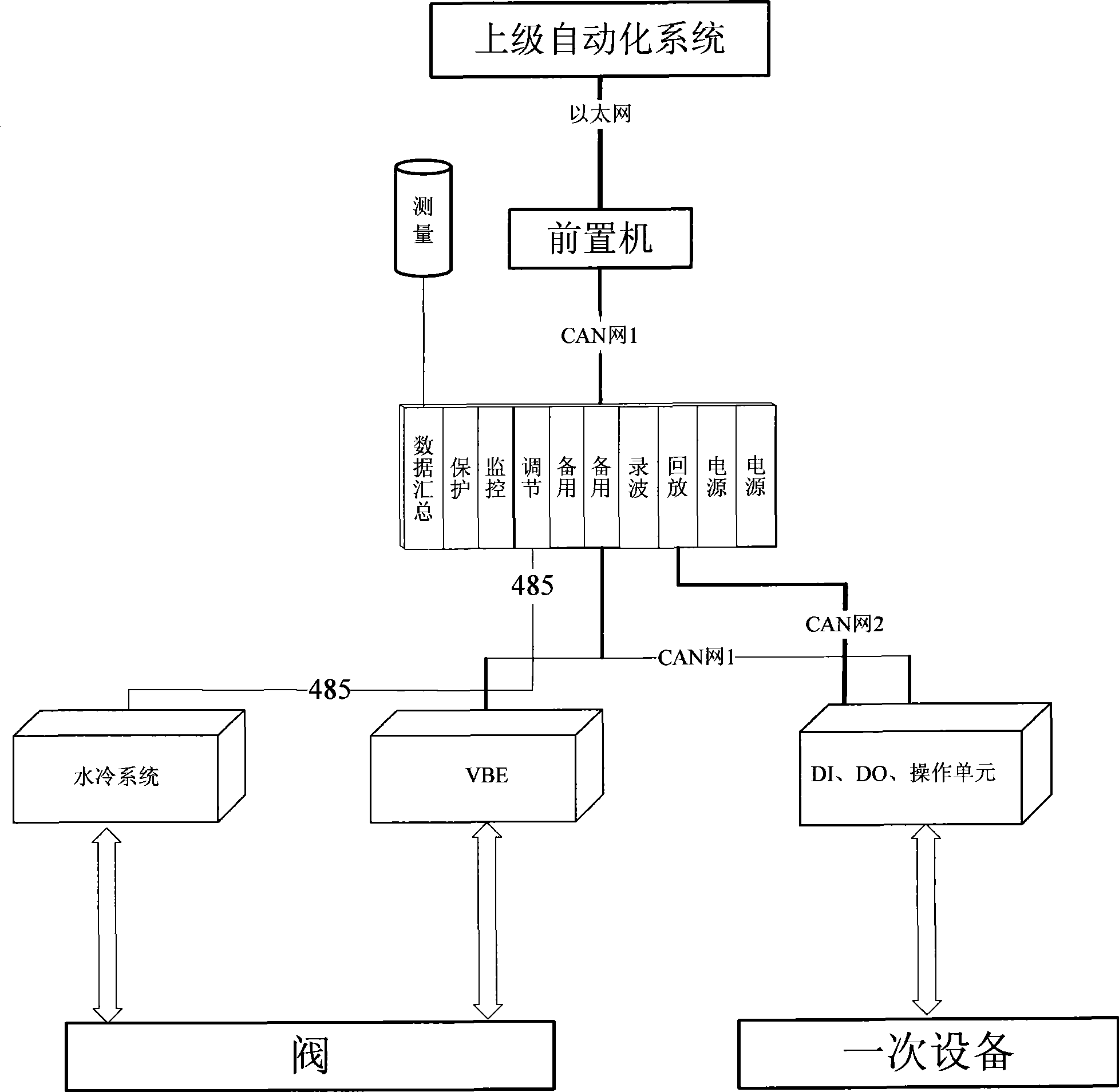

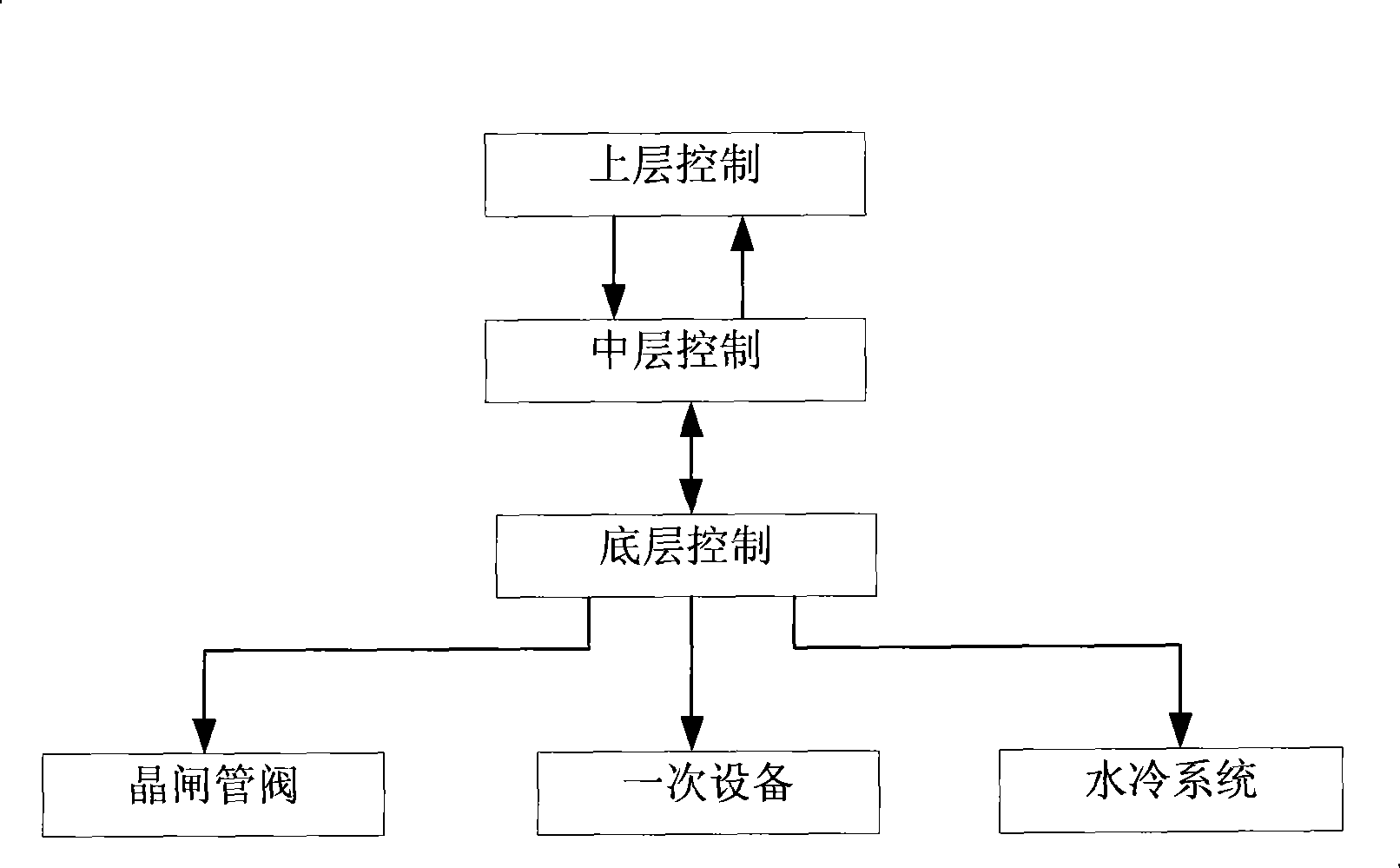

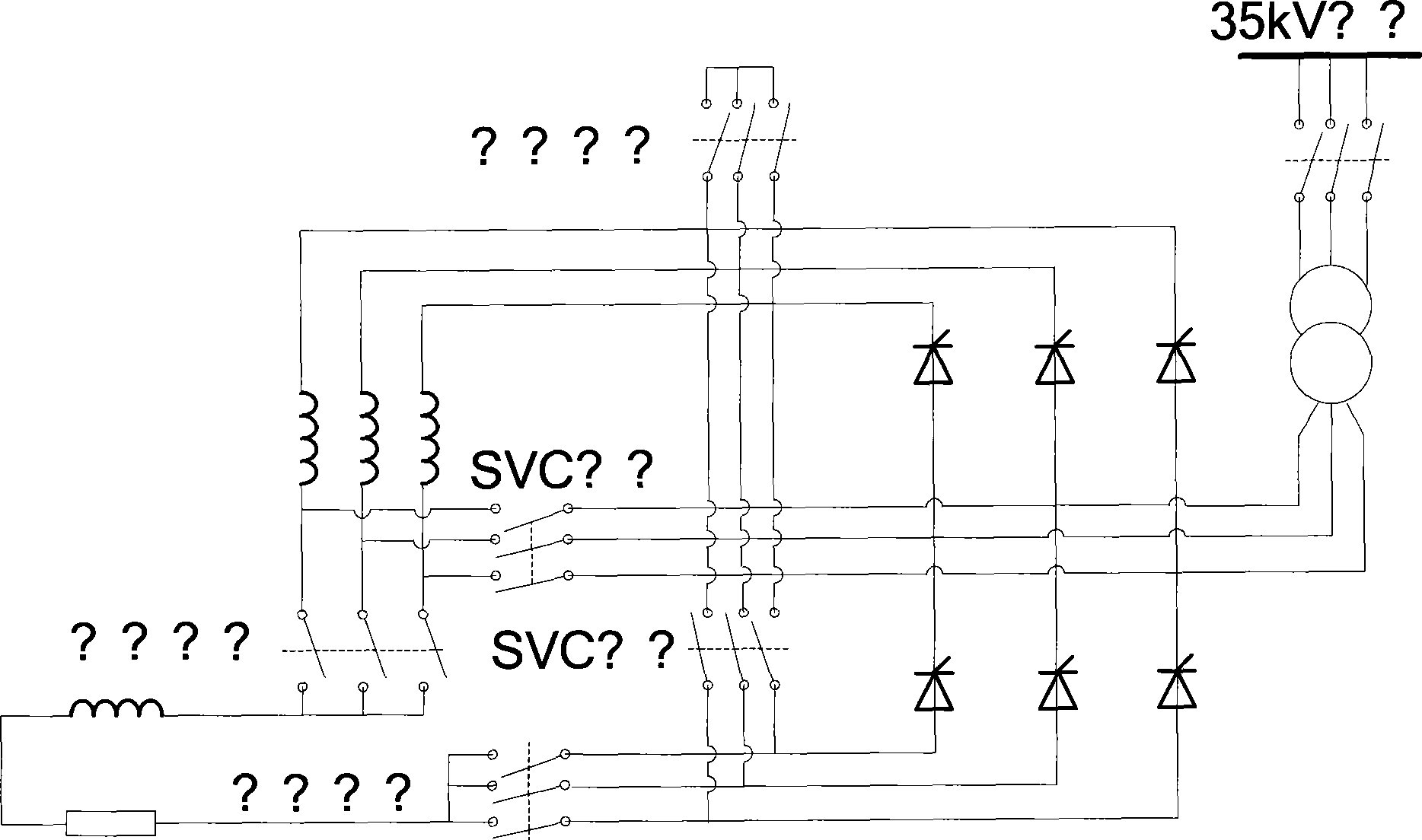

[0023] as attached Figure 4 As shown, the specific realization method of reconfiguring the working mode of the compound device into a static var compensation device is given. The monitoring system closes the SVC knife switch and opens the ice-melting knife switch after receiving the SVC working mode switching command and the knife switch automatic operation command from the operator on duty. After the knife gate operation is completed, the primary equipment connection method is as follows: the wiring of the thyristor valve group forms an anti-parallel connection, three phase-controlled reactors are respectively connected in series behind each phase of the thyristor valve group, and the three-phase thyristor valve group is connected in a delta connection form. The low voltage side of the rectifier transformer. The entire reconfiguration process doe...

Embodiment 2

[0024] Example 2: The working mode of the compound device is reconfigured to the mode of the DC ice-melting device

[0025] as attached Figure 5 As shown, the specific implementation method of reconfiguring the working mode of the compound device into a DC ice melting device is given. The monitoring system opens the SVC knife switch and closes the ice-melting knife switch after receiving the ice-melting working mode switching command and the knife switch automatic operation command from the operator on duty. After the knife switch operation is completed, the primary equipment connection method is: the positive and negative poles of two sets of thyristor valve groups are connected end-to-end to form a series connection form, and three phase-controlled reactors are connected in parallel as smoothing reactors to the output side of the DC bus. The thyristor valve group has a large margin in the first design, and the reconfiguration method does not need to increase the capacity o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com