Self-aligning gate construction nano field-effect transistor and preparation thereof

A field effect transistor and gate structure technology, applied in the field of self-aligned field effect transistors, can solve problems such as the inability to freely select metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

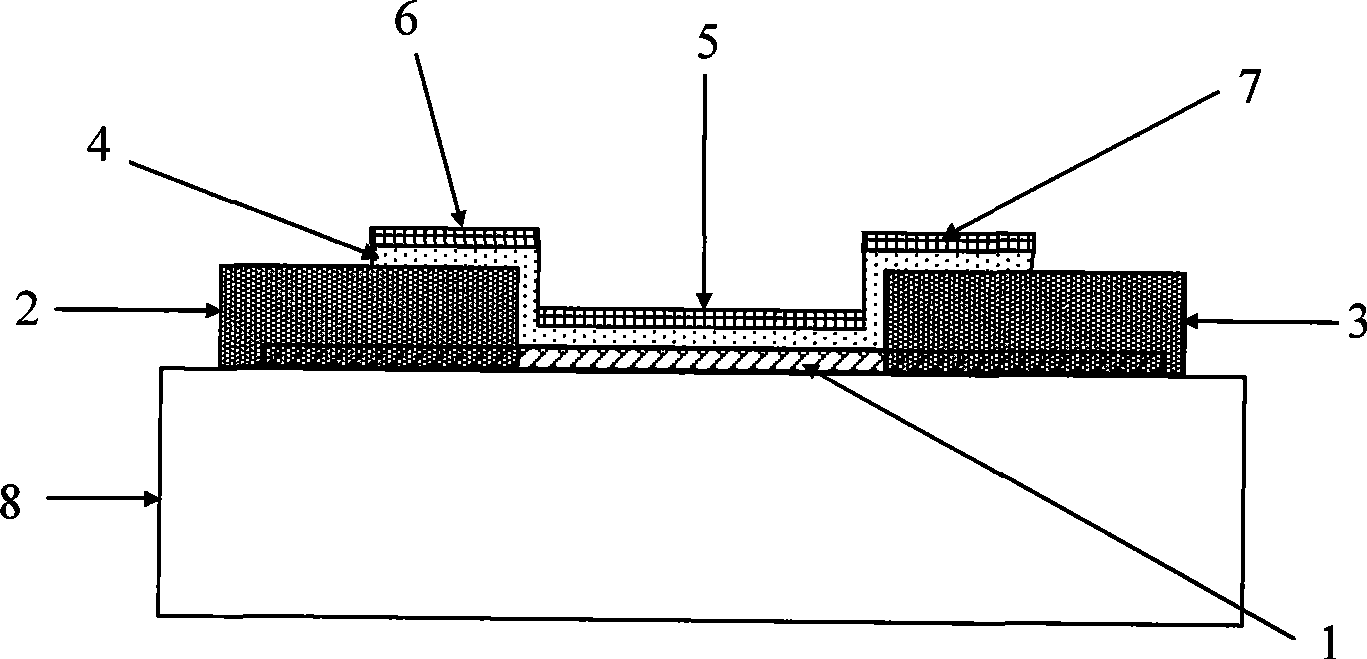

[0031] Such as figure 1 The shown metal scandium as the source and drain electrodes, HfO 2 The n-type self-aligned carbon nanotube field effect transistor is a gate dielectric and metal Ti is a gate electrode. The two Sc electrodes on the carbon nanotubes 1 distributed on the insulating substrate 8 are source electrodes 2 and drain electrodes 3 respectively, the gate dielectric layer is a hafnium oxide film 4 grown by ALD, and the gate electrode layer is a metal film grown by evaporation or sputtering , the portion 5 between the source and drain electrodes is disconnected from the portions 6 and 7 above the source and drain electrodes. Concrete preparation steps are as follows:

[0032] 1. Form the shape of the source and drain electrodes on the semiconductor carbon nanotubes by photolithography, evaporate a layer of Sc metal layer with a thickness of 80 nanometers as the source and drain electrode layers, and then put the sample into acetone to remove the unnecessary The m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com