Method for preparing polyhydroxy taxone and paclitaxel

A technology of polyhydroxytaxane and paclitaxel, which is applied in the field of natural product development or the manufacture of pharmaceutical raw materials, can solve the problems of waste of precious natural resources, etc., and achieve the effect of increasing resource utilization, reducing loss, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

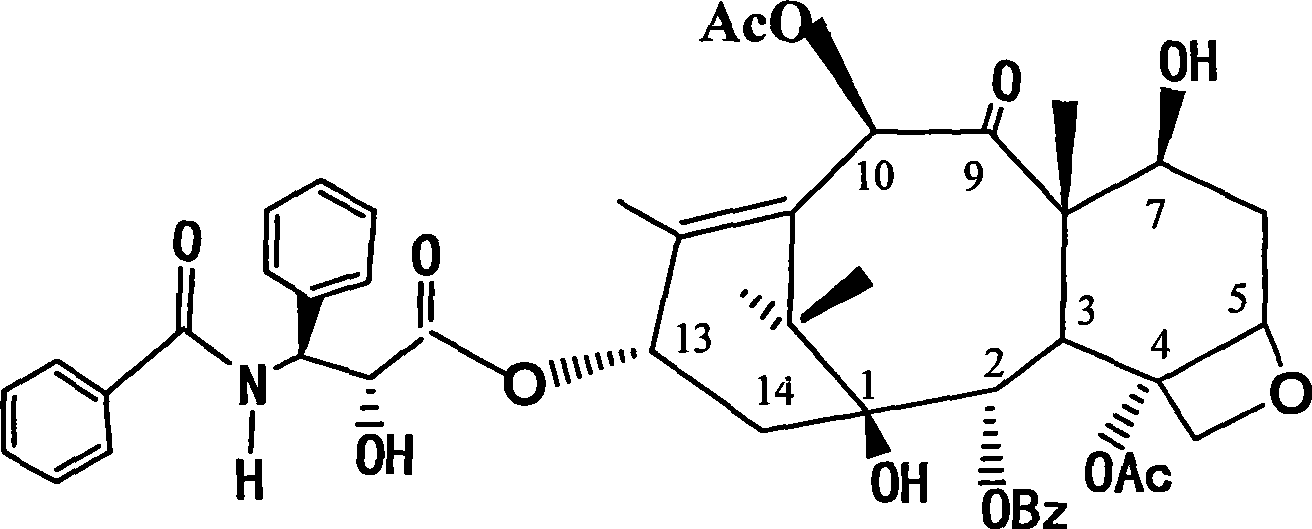

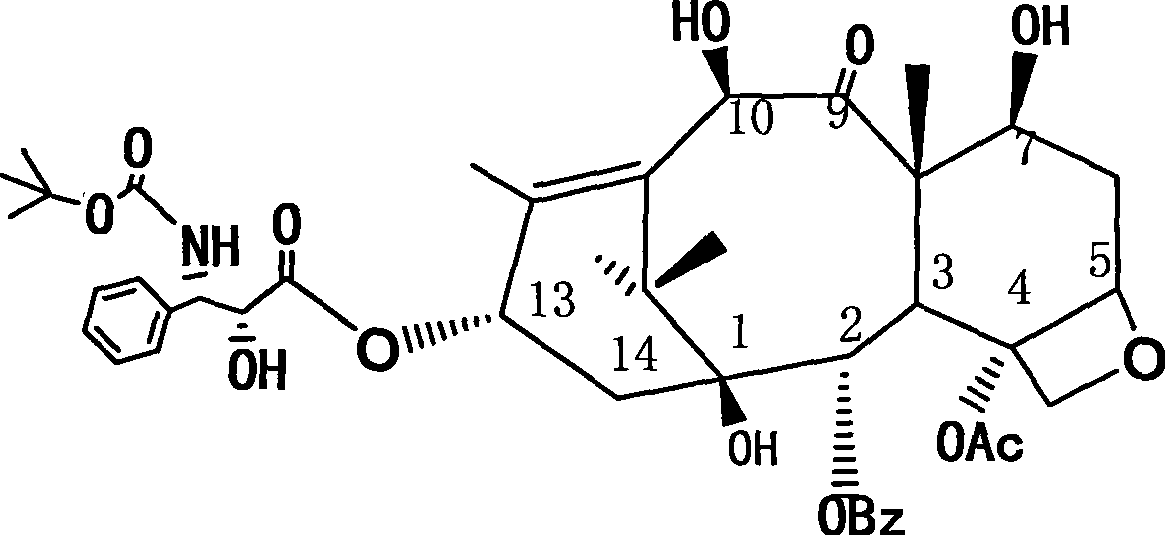

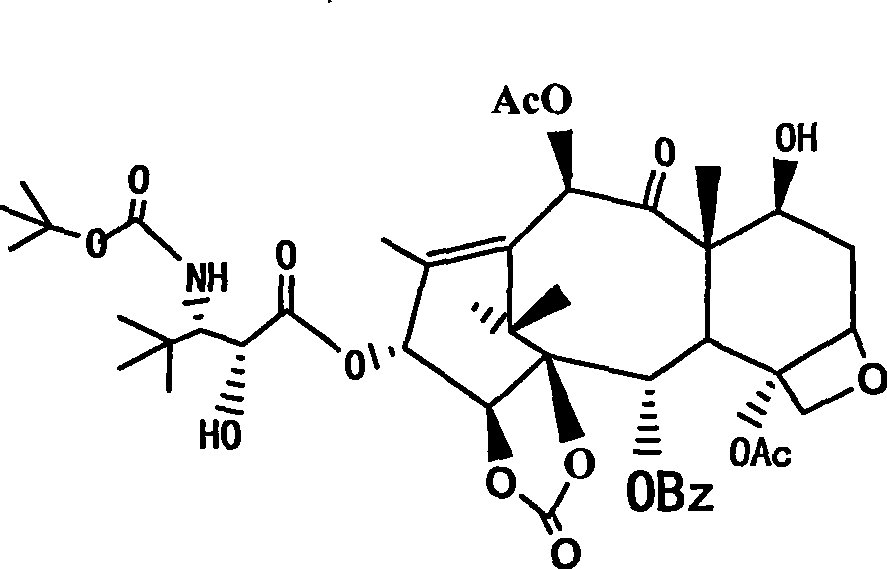

Image

Examples

Embodiment 1

[0045] Example 1 Simultaneous preparation of paclitaxel and polyhydroxytaxane from Chinese yew branches and leaves extract (1) Resin column separation step: get 10 g of Chinese yew branches and leaves methanol extraction concentrated extract, and analyze by HPLC containing 0.2% paclitaxel ( 20 mg), containing about 5.7% (570 mg) of baccatin VI, dissolved in methanol, loaded onto the resin column of non-polar macroporous styrene adsorption resin XAD16, washed with 30% methanol-containing aqueous solution, and washed away the water-soluble Impurities or pigments; then eluted with 3 times the column volume of 50% methanol-containing aqueous solution, collected the eluate, evaporated the methanol to dryness, added an equal volume of ethyl acetate as the extraction solvent for liquid-liquid extraction, collected ethyl acetate The ester layer was evaporated to dryness to obtain 1.45g of macroporous resin column separation crude product, which contained 1.3% (18.8 mg) of paclitaxel an...

Embodiment 2

[0051] Example 2 Simultaneous preparation of paclitaxel and polyhydroxytaxane from Chinese yew cell culture extract

[0052] (1) Resin column separation step: take 5 g of the concentrated extract from Taxus chinensis cells extracted with methanol, and analyze by HPLC, containing 1% (50 mg) of paclitaxel and about 16% (800 mg) of Yunnanningin. Dissolve in methanol, load on the resin column of non-polar macroporous styrene adsorption resin XAD1180, wash with methanol containing 20% aqueous solution to wash away water-soluble impurities or pigments; then use 3 times column volume with 80% methanol aqueous solution Elution, collect the eluent, evaporate the methanol to dryness, add an equal volume of chloroform for liquid-liquid extraction, collect the chloroform layer, evaporate to dryness, and obtain 2.65 g of the crude product separated by the macroporous resin column, which contains 1.8% paclitaxel by HPLC analysis (47mg), containing about 30% (795mg) of Yunnan Ning; the yie...

Embodiment 3

[0059] Example 3 Simultaneous preparation of paclitaxel and polyhydroxytaxane from southern yew branches and leaves extract

[0060] (1) Resin column separation step: Get 1Kg of the concentrated extract after the methanol extraction of the branches and leaves of Taxus chinensis, containing 0.18% (1.8g) of paclitaxel and about 5.5% (55g) of baccatin VI (BVI) through HPLC analysis. Dissolve it with methanol, load it on the resin column of non-polar macroporous styrene adsorption resin XAD16, wash it with an aqueous solution containing 40% methanol to wash away water-soluble impurities or pigments; then use 3 times the volume of the column with an aqueous solution containing 70% methanol Elution, collect the eluate, evaporate the methanol to dryness, add an equal volume of dichloromethane as the extraction solvent for liquid-liquid extraction, collect the dichloromethane layer, evaporate to dryness, and obtain 1.43g of macroporous resin column separation crude product, According ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com