Preparation method of high-purity superfine metal molybdenum powder

A metal molybdenum powder, high-purity technology, applied in the field of preparing high-purity ultra-fine metal molybdenum powder, can solve the problems of high treatment cost, ecological environment threat, incomplete treatment, etc., and achieve the effects of high added value, emission reduction, and high impurity content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

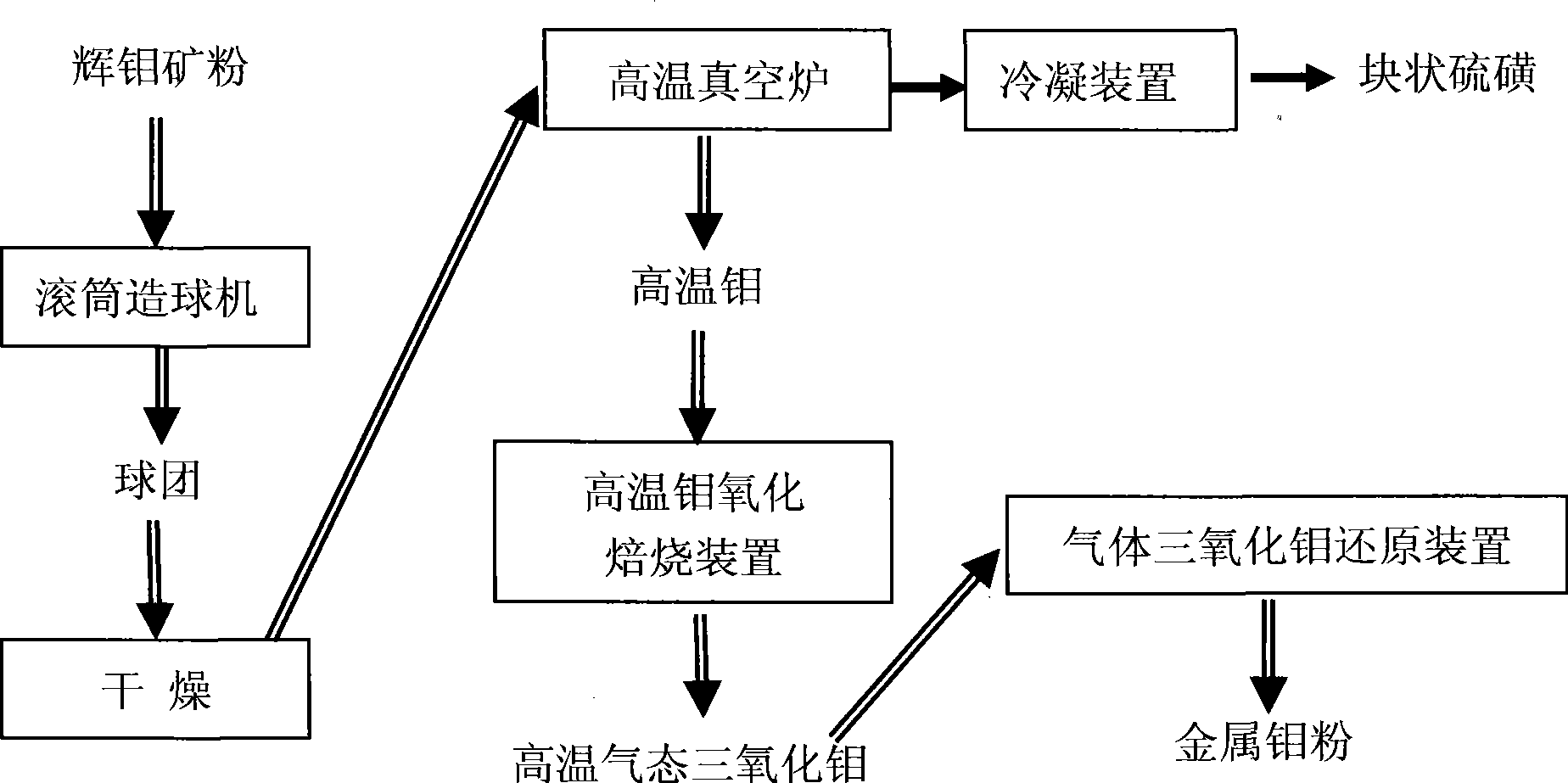

[0025] Such as figure 1 Shown: the method for preparing high-purity ultrafine metal molybdenum powder of the present invention, its concrete process step is:

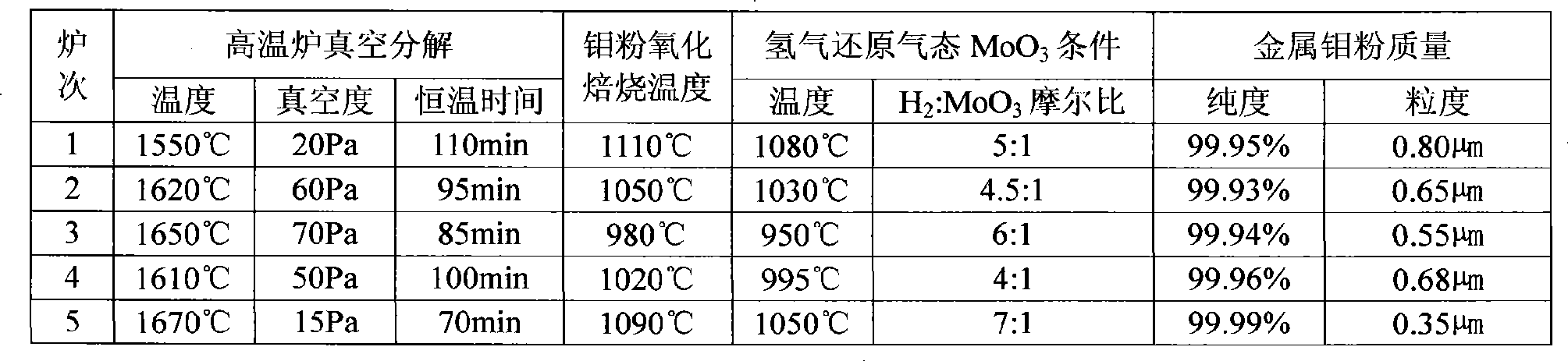

[0026] (1) First, the molybdenite is pelletized by a drum pelletizer with a particle size of about 5mm to 15mm; due to the large amount of gas generated during the vacuum decomposition process, if the particle size of the powder is too small, it is easy to be entrained by the airflow in the vacuum, so , the present invention also needs to make the molybdenite powder into a ball or a block, and the current disc pelletizer or drum pelletizer can produce the pellets required by the present invention, and the particle size is preferably 1mm to 20mm; The pellets are dried; the dried pellets are sent to a high-temperature vacuum furnace for vacuum decomposition. According to research, when the temperature is selected to be 1500°C to 1700°C during the process of decomposing molybdenite in a high-temperature vacuum furnace, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com