Steel rail defect detection method by electromagnetical ultrasonic technology and device thereof

An electromagnetic ultrasonic and defect detection technology, applied in the direction of measuring devices, using ultrasonic/sonic/infrasonic waves, using sound waves/ultrasonic/infrasonic waves to analyze solids, etc., can solve the problems of reduced environmental adaptability, limited detection speed, and increased detection costs. Achieve the effects of strong environmental adaptability, improved detection speed, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

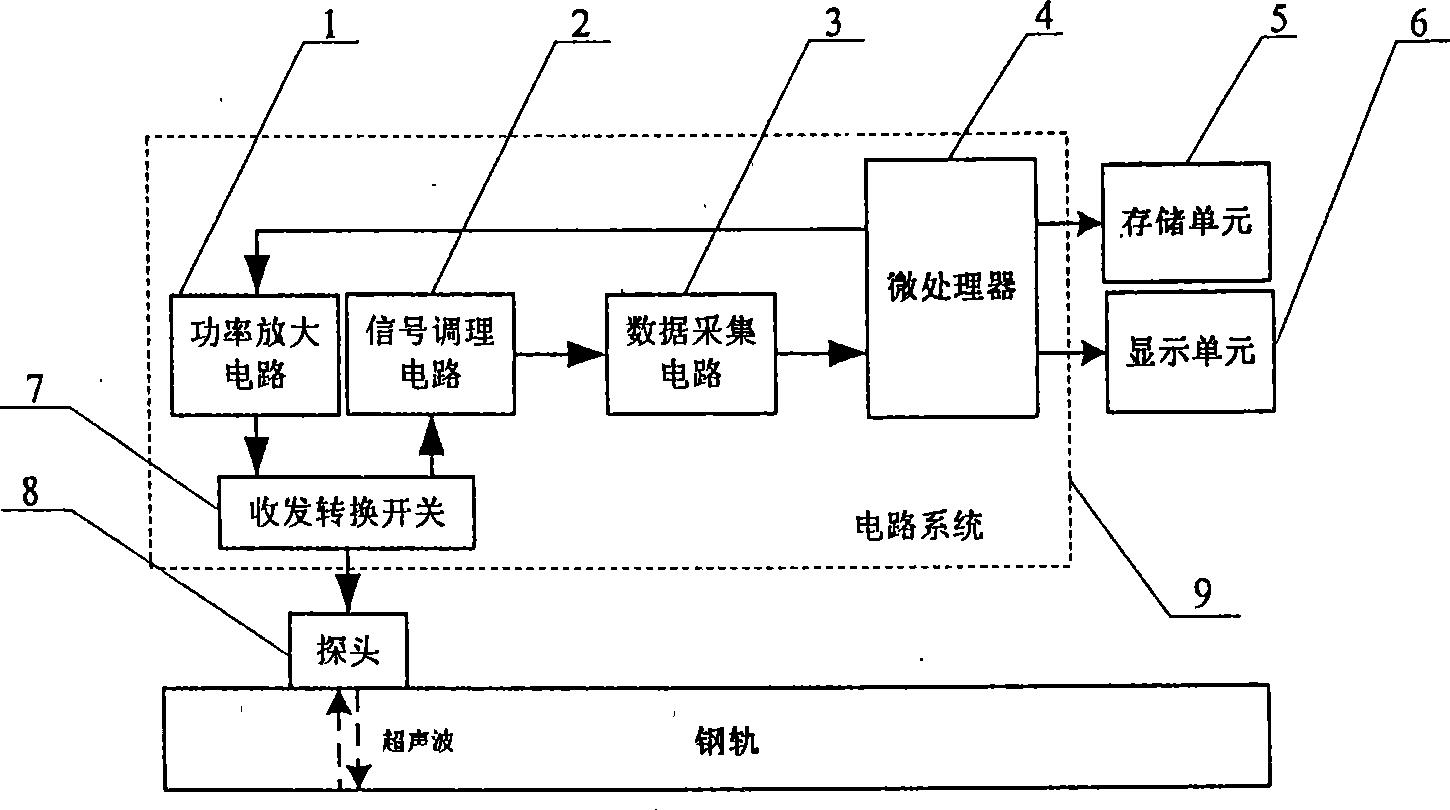

[0033] Embodiment 1, combining figure 1 , the present invention is an electromagnetic ultrasonic technology rail defect detection device, which is composed of a probe (8), a circuit system (9), a storage unit (5) and a display unit (6). The probe (8) is connected to the circuit system (9), and the circuit system (9) is respectively connected to the storage unit (5) and the display unit (6). The circuit system (9) includes a transceiving switch (7), a power amplifier circuit (1), a signal conditioning circuit (2), a data acquisition circuit (3) and a microprocessor (4). Described transceiving changeover switch (7) connects power amplifying circuit (1) and signal conditioning circuit (2) respectively, and power amplifying circuit (1) connects microprocessor (4), and signal conditioning circuit 2 connects data acquisition circuit (3) , the data acquisition circuit (3) is connected to the microprocessor (4), and the microprocessor (4) is respectively connected to the storage unit...

Embodiment 2

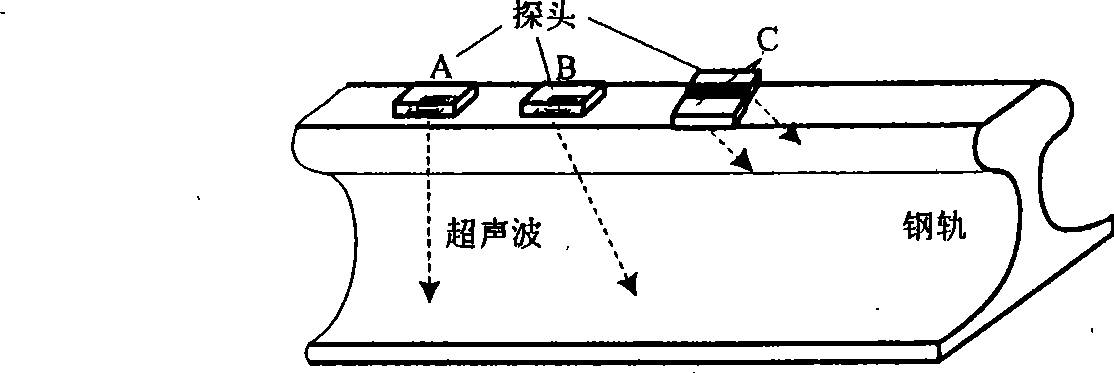

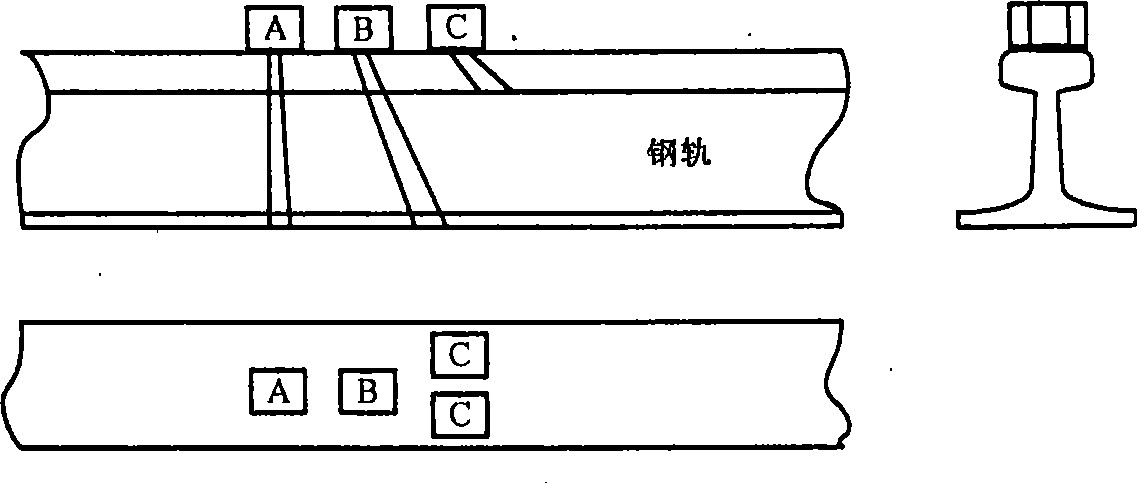

[0035] Example 2, combined with figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , the arrangement of the probe on the rail tread of the present invention adopts a special coil, which can easily generate ultrasonic body waves propagating to the inside of the rail, and properly adjust the frequency of the transmitted pulse, so that the ultrasonic wave can be injected into the rail at a certain angle. exist figure 2 , 3 Among them, A, B, and C are ultrasonic transducers composed of transmitting coils, magnets, and the rail itself. The transducers are placed on the rail tread, and defects at different positions of the rail can be detected more comprehensively by using different emission angles.

[0036] Probe A emits ultrasonic body waves perpendicular to the rail tread, which can detect rail waist and rail bottom defects; probe B is obliquely incident to the length of the rail, and can detect damage to screw holes; two probes C are obliquely incident to the length o...

Embodiment 3

[0039] Example 3, combined with Figure 5 , The excitation principle of the electromagnetic ultrasonic oblique incident body wave of the present invention is: the electromagnetic ultrasonic oblique incident body wave probe is composed of a magnet and an electromagnetic ultrasonic zigzag coil, and the working frequency is 1 MHz. The incident angle of the sound beam of the probe is determined by the wavelength of the sound wave and the turn spacing of the meandering coil. Reasonable adjustment of the transmission frequency and the turn spacing of the meandering coil can make the ultrasonic wave incident in a suitable direction. Let the incident angle of the obliquely incident body wave be θ, then

[0040] sin θ = λ 2 l

[0041] Where λ - the wavelength of the sound wave;

[0042] l—the turn spacing of the meander coil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com