Monotubular anaerobic-aerobic composite microencapsulation biological fluidized bed automatic control apparatus

A biological fluidized bed and anaerobic fluidized bed technology, applied in the field of single-cylinder anaerobic-aerobic composite microencapsulated biological fluidized bed automatic control equipment, can solve the problem of high energy consumption, difficult surface properties, shape and pore structure Manual control of transformation, high density and other problems, to achieve the effect of large effective volume, innovative, convenient addition and recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

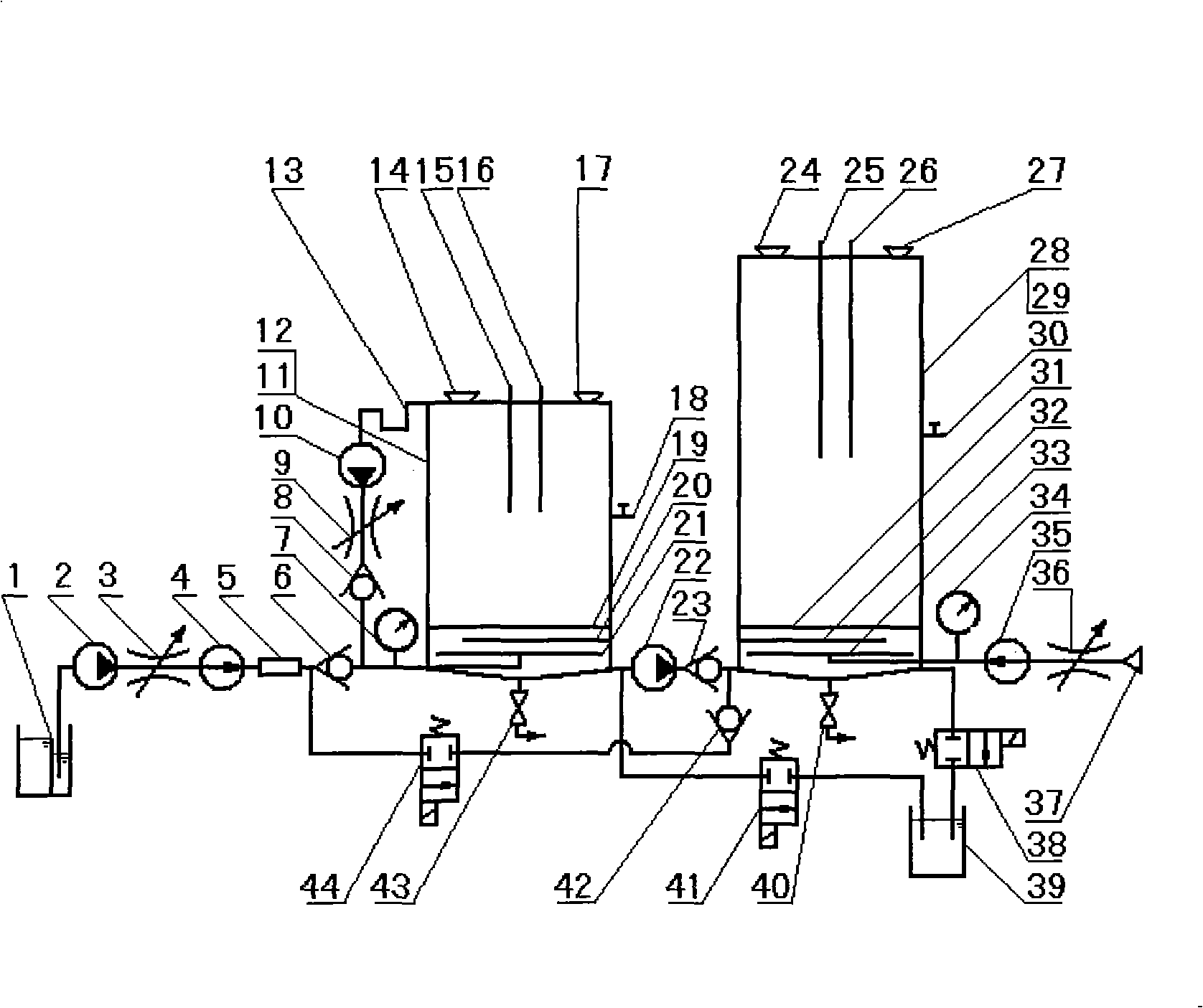

[0010] The present invention focuses on the following factors: (1) due to the combination of biological microcapsule technology, the present invention uses the entire fluidized bed as a reaction zone, without the need to set up a special settling zone, settling zone and mud-water separation zone in addition. It overcomes the shortcomings of the three-phase separation of solid, liquid and gas in the general activated sludge biological fluidized bed. Considering that the general activated sludge biological fluidized bed has a large height-to-diameter ratio, resulting in additional waste of power and effective volume, Therefore, in the present invention, under the same working volume, the aspect ratio of the fluidized bed is designed to be 1.5-2, so that the fluidized state can be realized under the action of relatively small air flow or water flow. Considering that aerobic treatment generally has a large amount of treatment and takes a long time, the volume of the aerobic part is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com