Dry powder biological demulsifying agent and Bacillus alcaligenes applied to petroleum extraction

A technology of biological demulsifier and Alcaligenes, applied in the direction of microorganism-based methods, microorganisms, biological water/sewage treatment, etc., can solve the problems of health impact, increased treatment cost, difficult to remove, etc., and achieve a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Alcaligenes screening:

[0021] Take 3g of oil-contaminated Karamay Oilfield soil and add it to 125mL of the following medium (L -1 ): NaNO 3 8.0g, K 2 HPO 4 2.0g, KH 2 PO 4 3.0g, MgSO 4 ·7H 2 O 0.2g, crude oil 4% (V / V), CaCl 2 2H 2 O 1.0g, MnSO 4 1.0 g, EDTA 1.4 g, pH=7.0. Cultivate in a shaker with a temperature of 30-35°C and a rotation speed of 130-150rpm, with a cycle of 5-7 days, and after 3 cycles, a strain that can be used for petroleum is successfully isolated from it by dilution coating method. Emulsion-breaking Alcaligenes (see figure 1 , the magnification of the sample in the figure is 10,000).

Embodiment 2

[0023] Preparation and use of dry powder biodemulsifier:

[0024] The whole culture solution of Alcaligenes was centrifuged at a high speed of 10000rpm to obtain a wet bacterial culture mixture, which was baked at 105°C for 24 hours and ground to obtain a dry powder (see figure 2 ). The dry powder biological demulsifier can be used at a temperature of 35-75°C, the dosage is 100-200mg / L, shake vigorously for 200 times, and stand for 2.5 hours to observe the demulsification effect.

Embodiment 3

[0026] Changes of surface tension and dehydration rate of Alcaligenes whole culture solution with culture time:

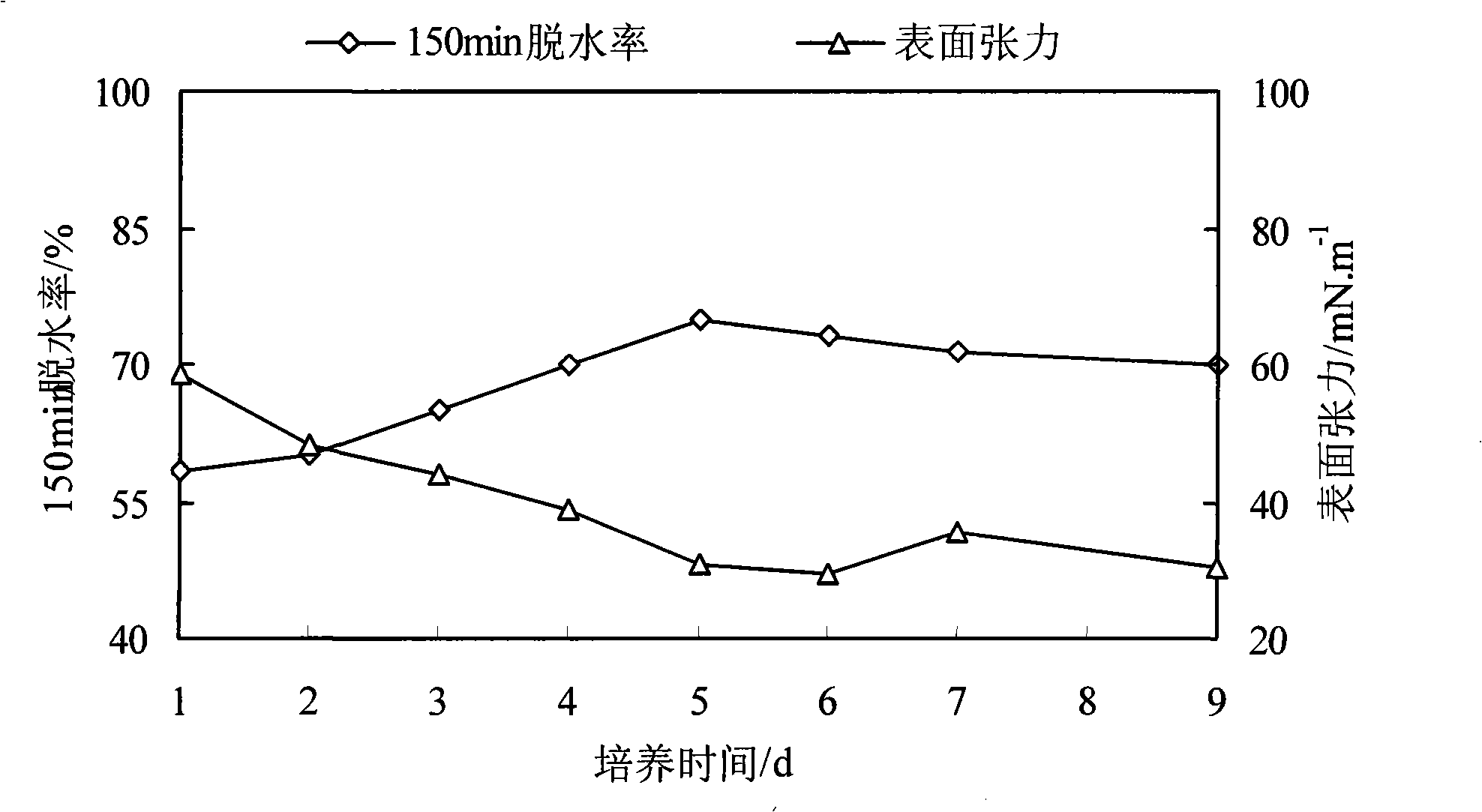

[0027] Use a surface tensiometer to measure the surface tension of the Alcaligenes full culture solution for different culture times, and add the full culture solution to the emulsion at a dosage of 10% (V / V), shake it vigorously for 200 times, and heat it at 35°C. Let it stand for 2.5 hours, observe its demulsification effect, the results are shown in image 3 .

[0028] Depend on image 3 It can be seen that the surface tension of the whole culture solution of Alcaligenes dropped from the initial 56.3mN / m to the lowest value of 29.2mN / m on the 6th day during the cultivation process, which shows that it has generated a certain biological surface activity during the cultivation process. agent. The demulsification effect also changed with the culture time. At the beginning of inoculation, the whole culture solution had almost no demulsification ability, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com