Method for preparing combined modified catalyst for processing coloring agent waste water

A dye wastewater and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., to achieve no secondary pollution, expand potential difference, and mild reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

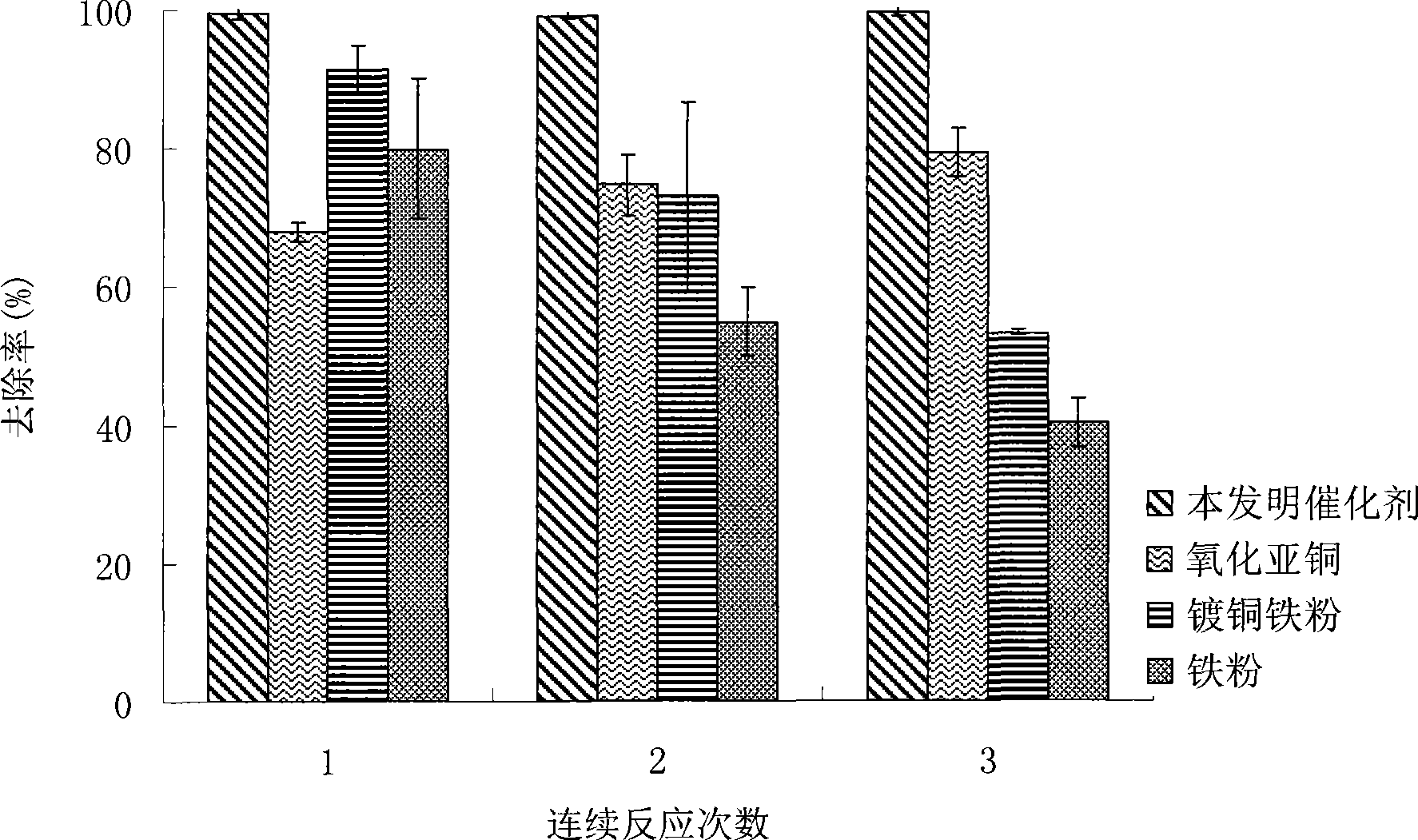

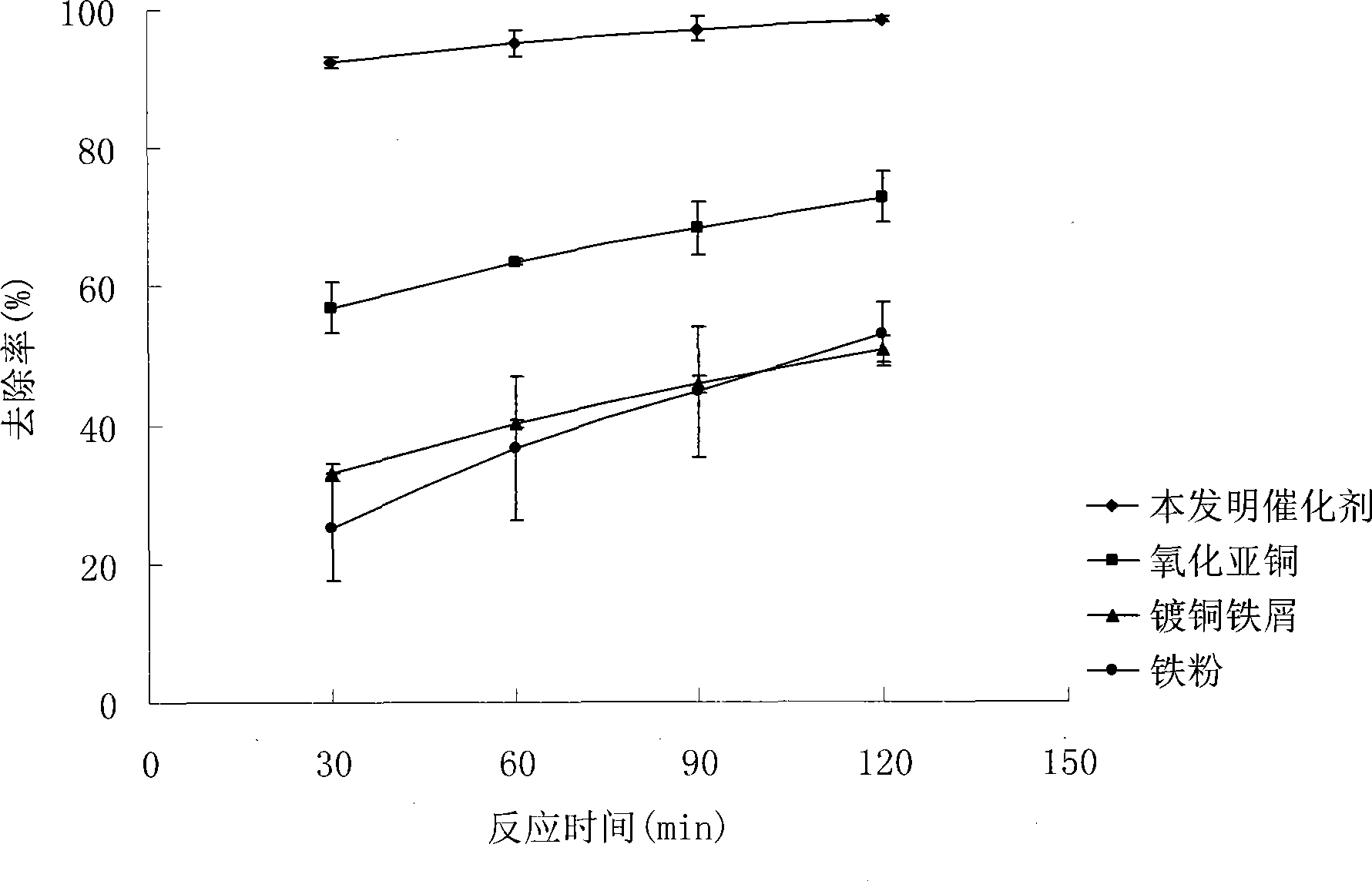

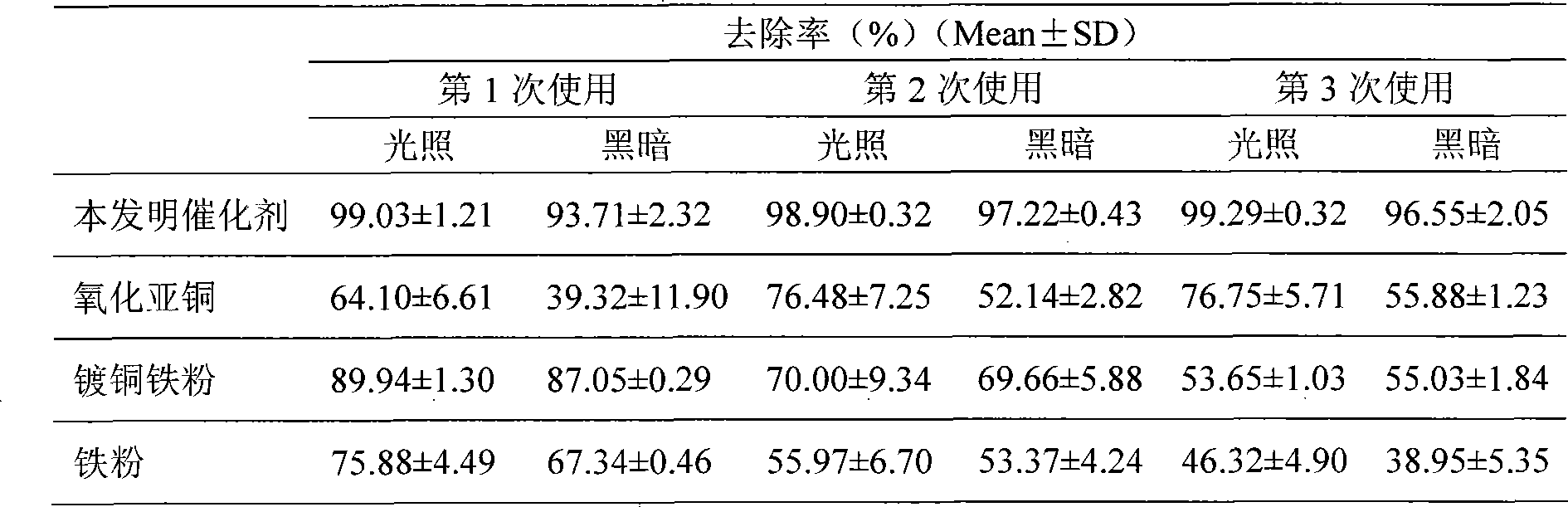

Examples

Embodiment 1

[0022] Catalyst method: add 100mL hydrazine hydrate to 200mL copper sulfate pentahydrate solution (concentration: 0.5mol / L) under vigorous stirring and age for 30min to obtain a reddish-brown suspension, in which the reddish-brown precipitate is mainly cuprous oxide and elemental copper; then slowly add 20g of industrial iron powder (purchased from Shenyang Daxing Metal Material Factory), stir for 2min, filter to obtain a precipitate, wash the precipitate with distilled water, and dry at 80°C to obtain a taupe composite powder. That is the catalyst. The filtrate obtained during the filtration can be reused.

Embodiment 2

[0035] The difference from Example 1 is that

[0036] Catalyst method: add 80mL hydrazine hydrate to 300mL copper sulfate pentahydrate solution (concentration: 0.2mol / L) under vigorous stirring and age for 15min, then slowly add 15g industrial iron powder, stir for 5min, and filter to obtain the precipitate. The precipitate was washed with distilled water and dried at 70°C to obtain the catalyst.

Embodiment 3

[0038] Catalyst method: add 150mL hydrazine hydrate to 250mL copper sulfate pentahydrate solution (concentration: 0.4mol / L) under vigorous stirring and age for 35min, then slowly add 30g industrial iron powder, stir for 4min, and filter to obtain the precipitate. The precipitate was washed with distilled water and dried at 100°C to obtain the catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com