Method for preparing gold alloys-containing catalyst

A technology for alloy catalysts and complex metals, applied in metal/metal oxide/metal hydroxide catalysts, molecular sieve catalysts, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

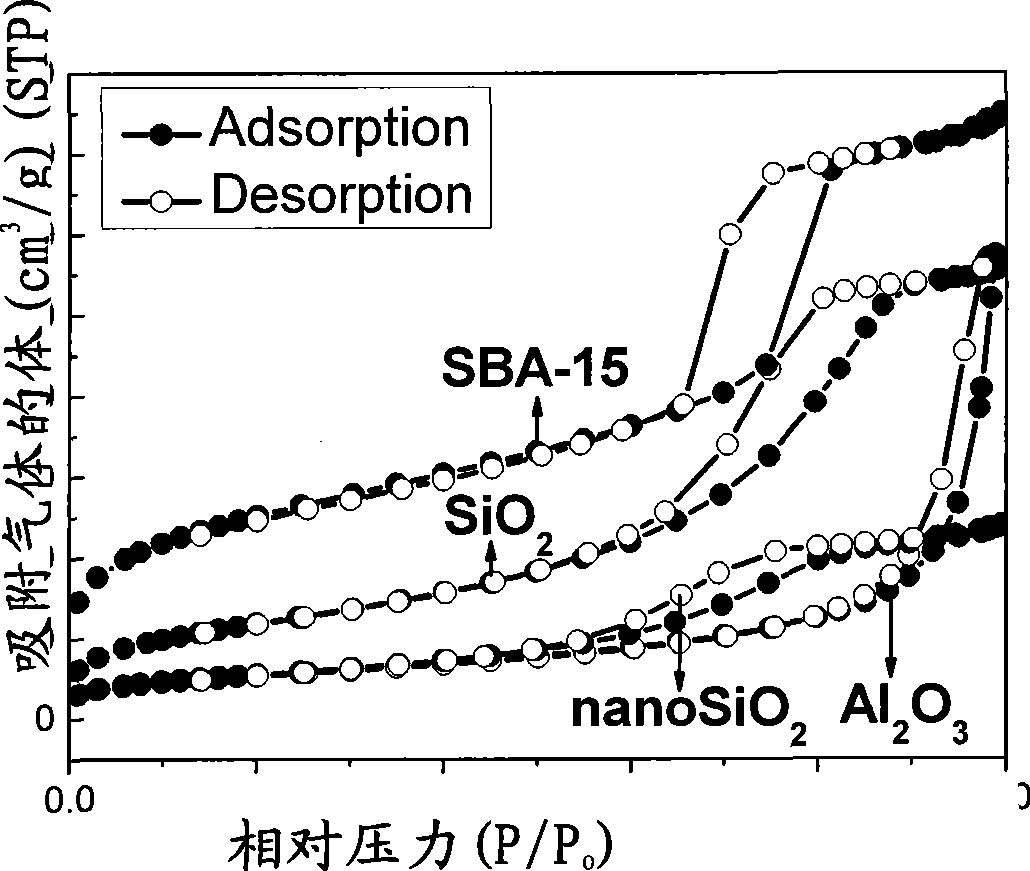

[0051] Example 1. Measure 200 mL of ethanol with a graduated cylinder into a 500 mL three-necked flask, and then add 10.00 g of 3-aminopropyltriethoxysilane (APTES) to prepare a solution. Accurately weigh 4.00g of SBA-15 powder and add it to the above solution. Place the three-necked flask in a water bath, stir magnetically, and reflux at 80°C for 24 hours. Then, it was filtered, washed with ethanol 3 times, and dried in an oven at 60°C for 6 hours. Get APTES-SBA-15.

Embodiment 2

[0052] Example 2. Measure 200 mL of toluene in a 500 mL three-necked flask with a graduated cylinder, and then add 10.00 g of 3-aminopropyltrimethoxysilane (APTMS) to prepare a solution. Accurately weigh 4.00 g of amorphous silica powder and add it to the above solution. Place the three-necked flask in a water bath, stir magnetically, and reflux at 80°C for 24 hours. Then, it was filtered, washed with toluene 3 times, and dried in an oven at 60°C for 6 hours. Get APTMS-SiO 2 .

Embodiment 3

[0053] Example 3. Measure 200 mL of isooctane in a 500 mL three-necked flask with a graduated cylinder, and then add 10.00 g of 3-mercaptopropyltrimethoxysilane (MPTMS) to prepare a solution. Accurately weigh 4.00g of amorphous nano silicon oxide powder and add it to the above solution. Place the three-necked flask in a water bath, stir magnetically, and reflux at 80°C for 24 hours. Then, it was filtered, washed with isooctane 3 times, and dried in an oven at 60°C for 6 hours. Get MPTMS-nanoSiO 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com