Biomass compact curing moulding process and special equipment therefor

A technology of solidifying and forming biomass, applied in the direction of biofuel, material forming press, solid fuel, etc., can solve the problems of low production efficiency, easy breakage, slow accumulation of economic benefits of enterprises, etc., and achieves the improvement of tissue density, The effect of enhancing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

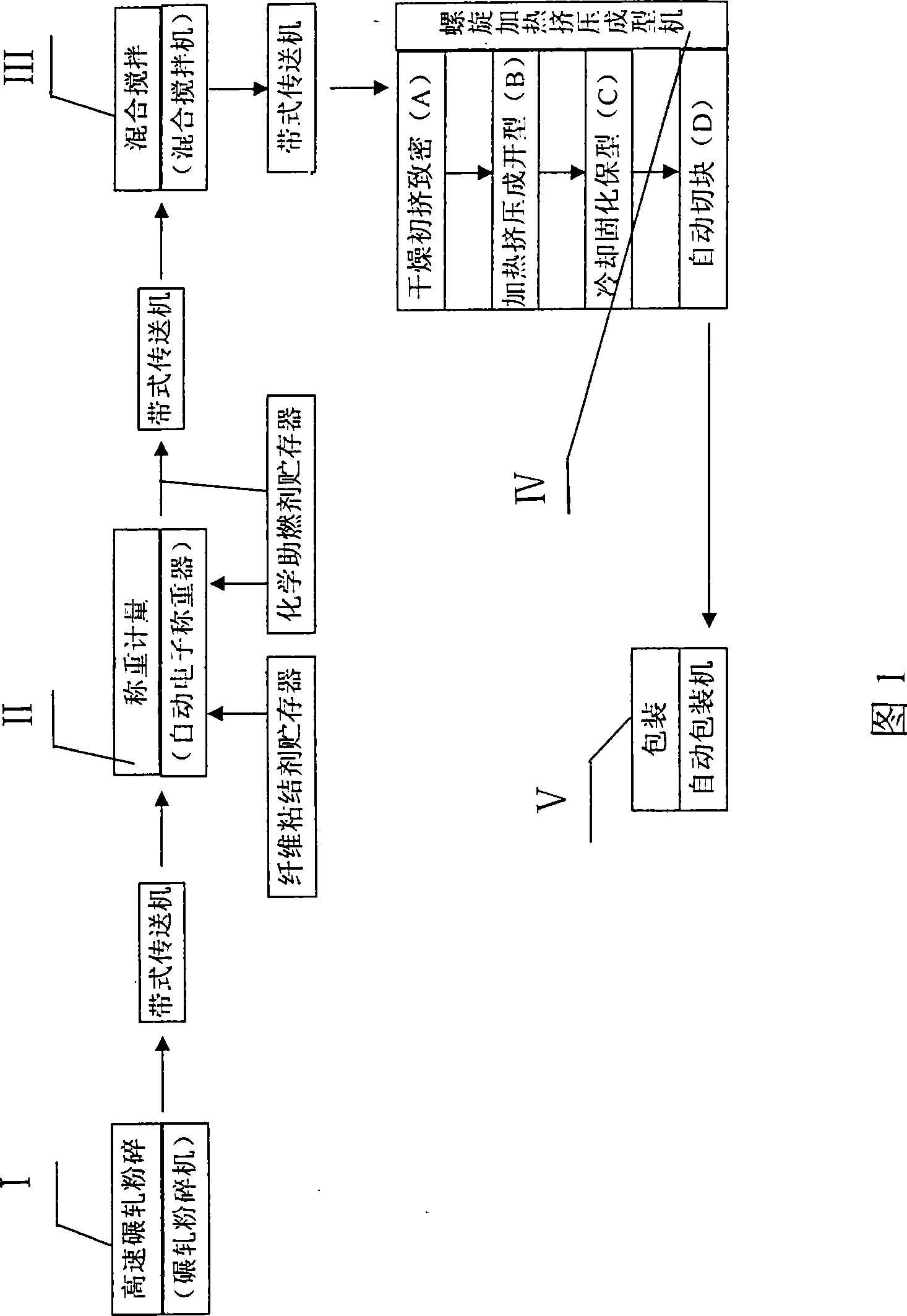

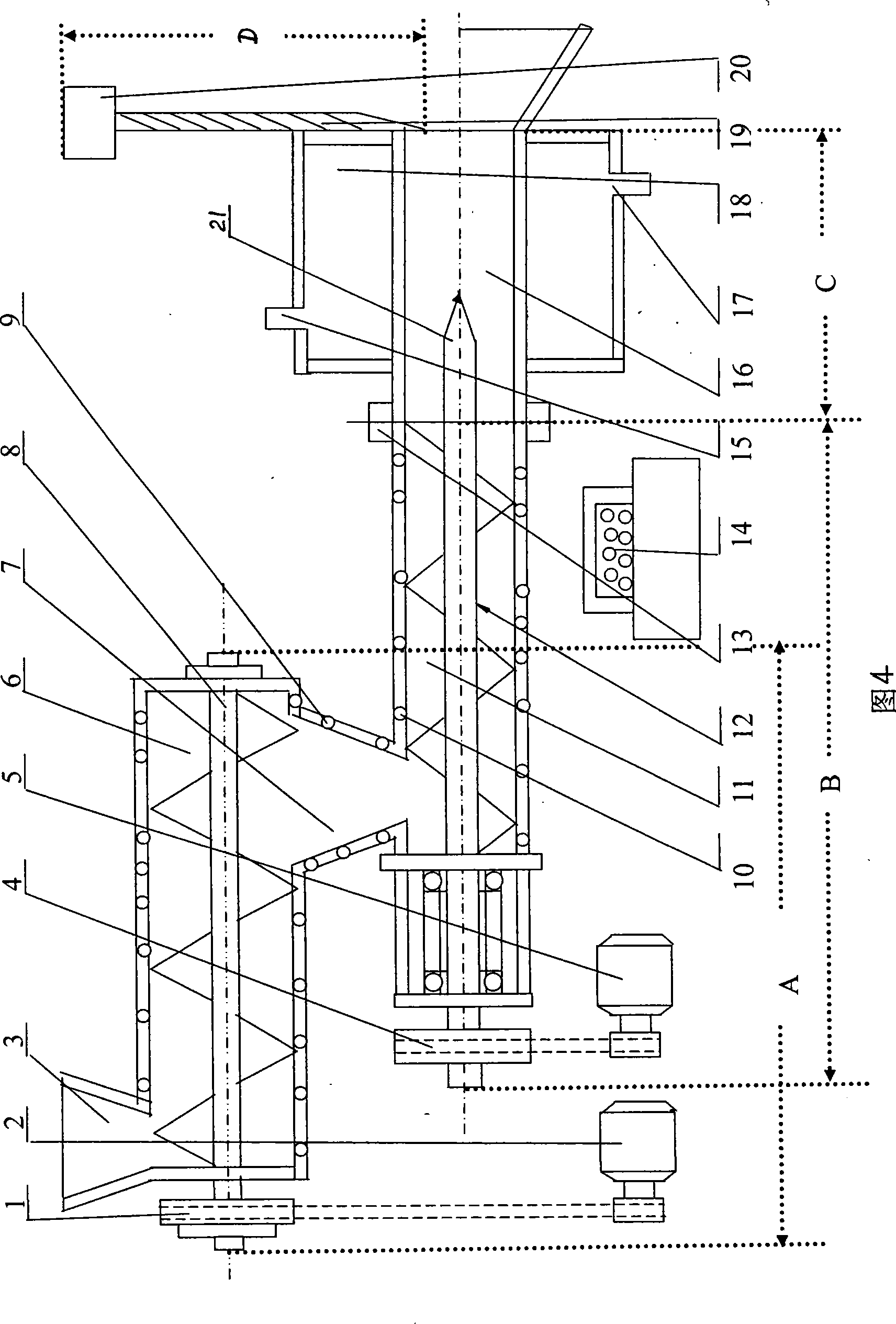

[0040] As shown in accompanying drawing 1: the process step of dense solidification molding of biomass of the present invention includes the following processing steps: high-speed rolling and crushing I, weighing and measuring II, mixing and stirring III, spiral hot pressing forming IV, automatic packaging V, the above five processes They are connected by a belt conveyor.

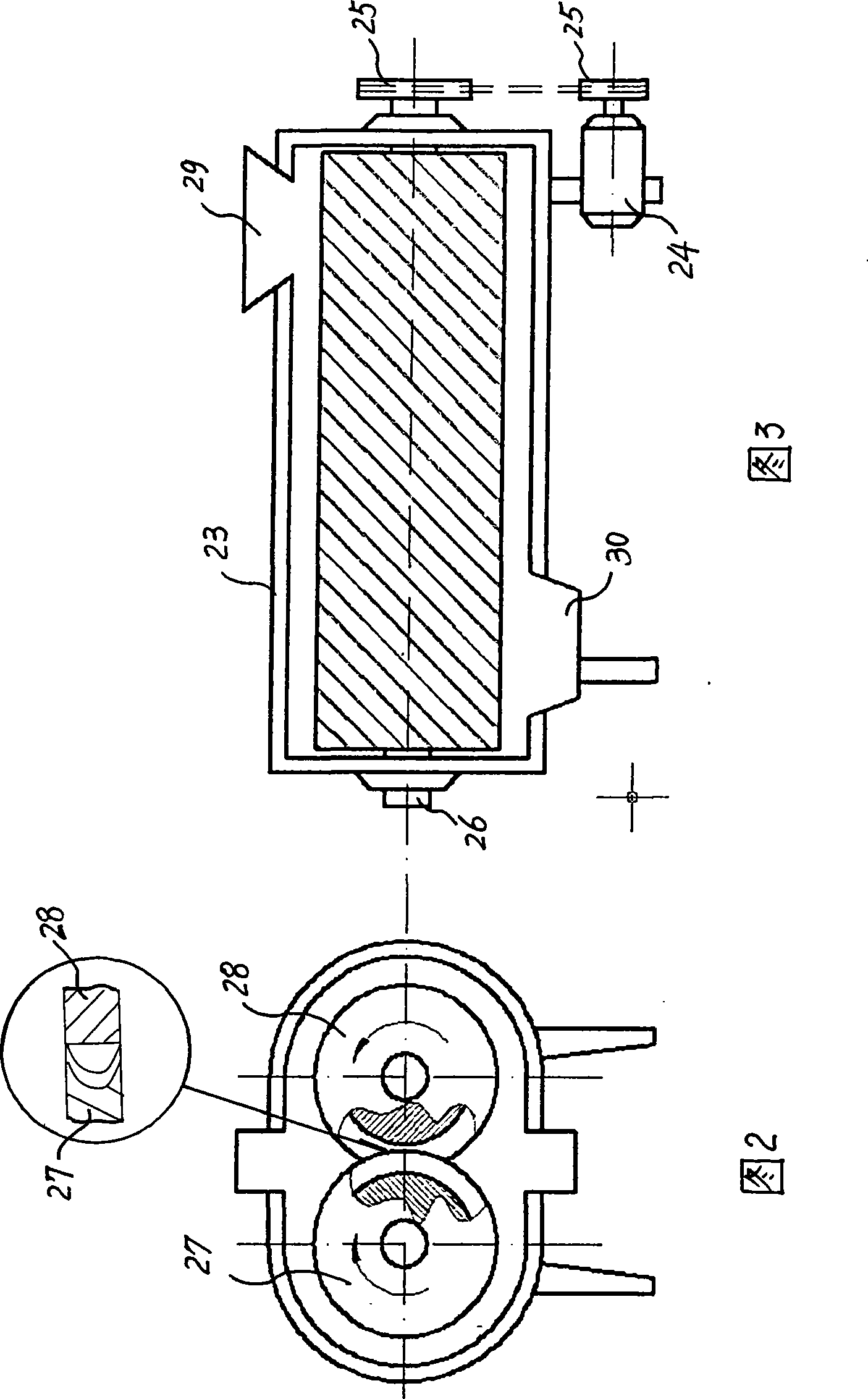

[0041] As shown in accompanying drawings 2 and 3: the high-speed rolling mill is composed of a housing 23, a motor 24, a pulley 25, a rotating shaft 26, a grooved active rolling roll 27, and a convex toothed passive rolling roll 28. , the grooved active rolling roll 27 and the passive rolling roll 28 with convex teeth arranged on the rotating shaft 26 are installed in the housing 23, with a feed inlet 29 and a discharge opening on the top of the housing 23. Port 30, the equipment implements rolling and crushing operations through two active rolling rolls 27 and passive rolling rolls 28 that rotate synchrono...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com