Aberration evaluation pattern,aberration evaluation method,aberration correction method,electron beam drawing apparatus,electron microscope,master,stamper

A technology for drawing equipment and aberration correction, applied in optomechanical equipment, microlithography exposure equipment, circuits, etc., can solve the problems of increasing aberration, difficulty in manufacturing reference samples, and tedious scanning of electron beams accurately, and achieve high The effect of recording density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

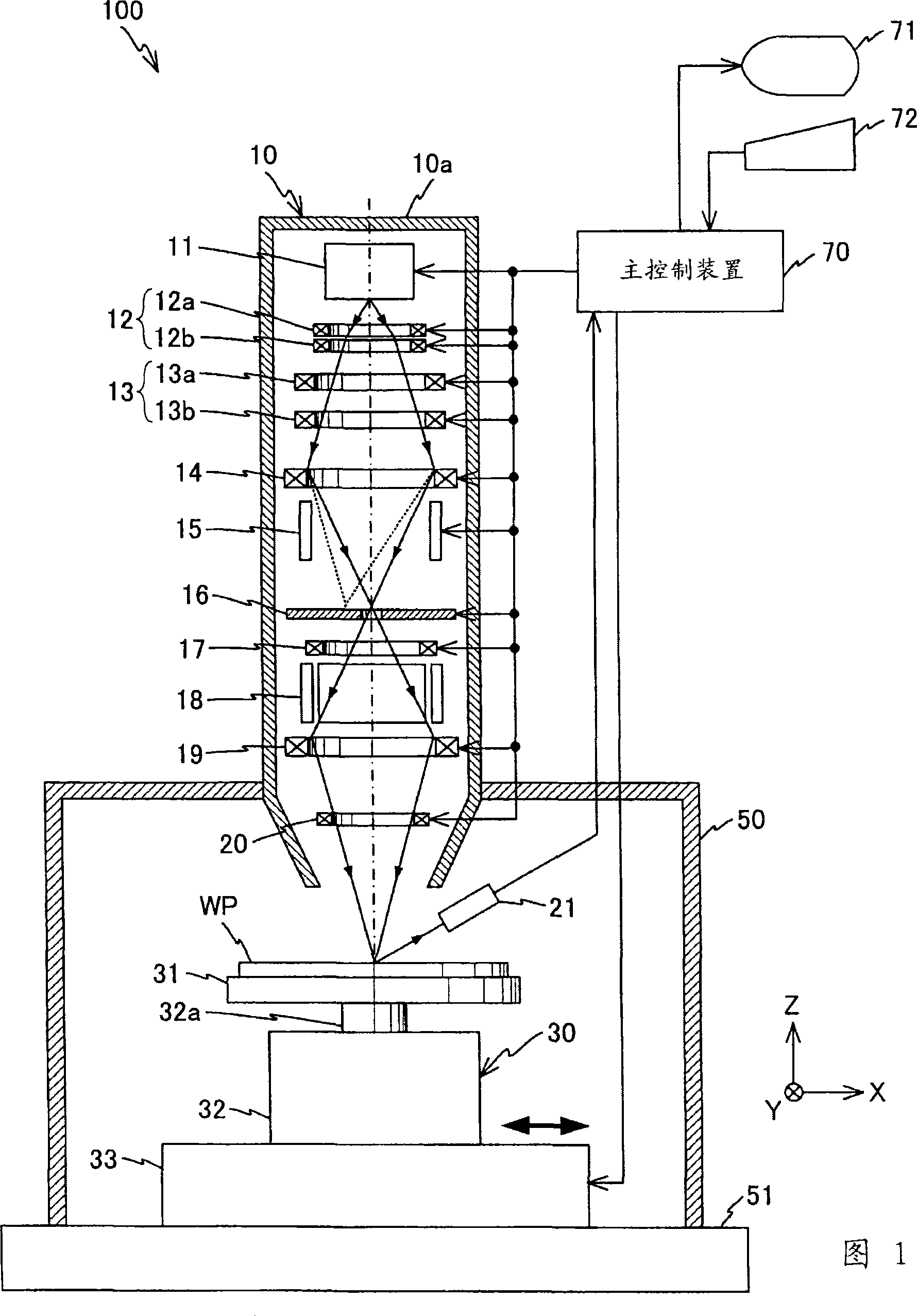

[0110] Hereinafter, a first embodiment of the present invention is described with reference to FIGS. 1 to 9 . FIG. 1 is a schematic diagram illustrating a drawing device 100 according to a first embodiment of the present invention. Depicting device 100 is achieved by, for example, at 10 -4 A device that irradiates an electron beam on a sample under a vacuum of Pa to draw a fine pattern on the drawing surface of the sample formed by coating a resist material.

[0111] As shown in FIG. 1 , the depiction apparatus 100 includes a turntable unit 30 on which a sample is mounted, an irradiation apparatus 10 for irradiating electron beams on the sample, a vacuum chamber 50 for accommodating the turntable unit 30, and a vacuum chamber for accommodating the turntable unit 30. The main control device 70 that controls these components of the drawing apparatus 100 is integrated.

[0112] The vacuum chamber 50 is a hollow member having a rectangular shape with an open bottom (−Z direction...

no. 2 example

[0146] Next, refer to Figure 10 to 15 describe the second embodiment of the present invention. It should be noted that the same reference symbols are used for the same or equivalent components as those of the first embodiment, and descriptions of these components are omitted or reduced.

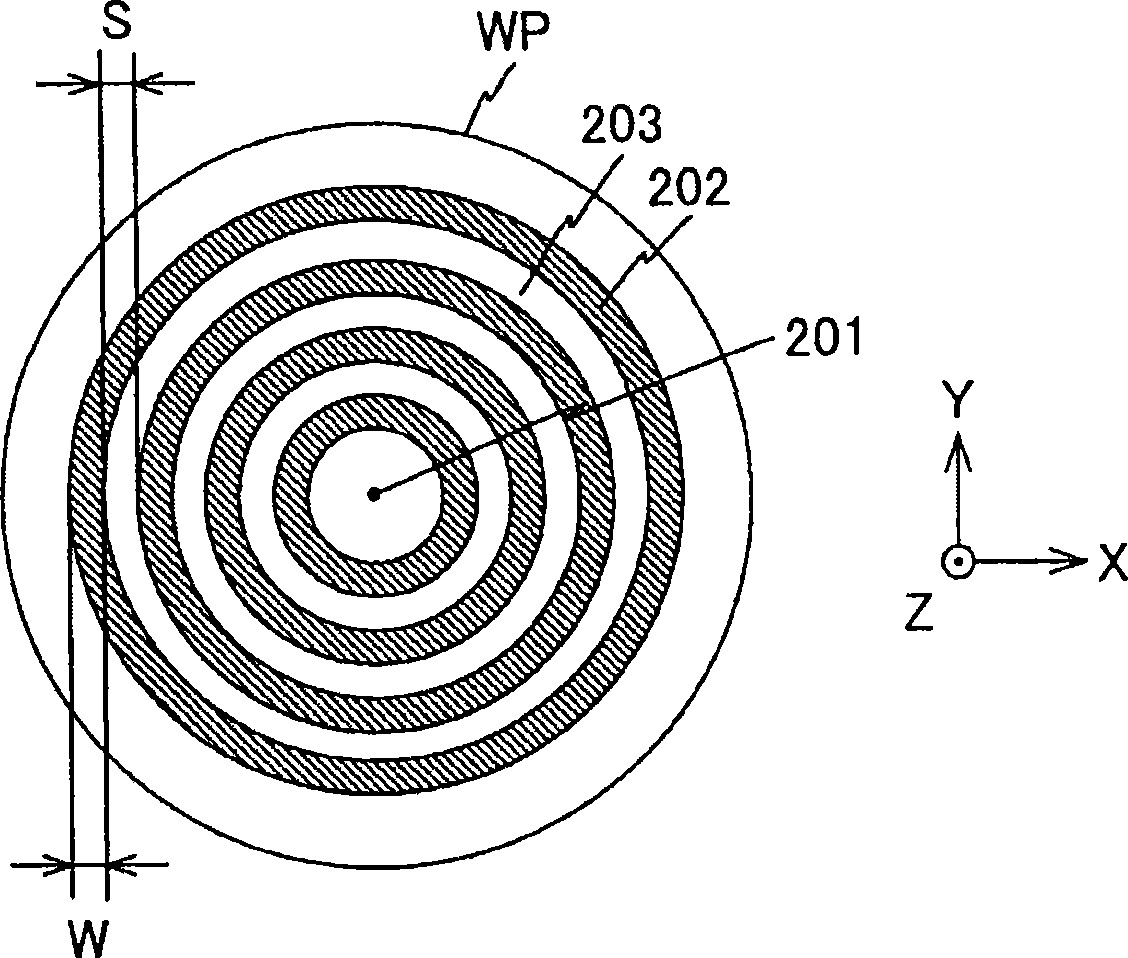

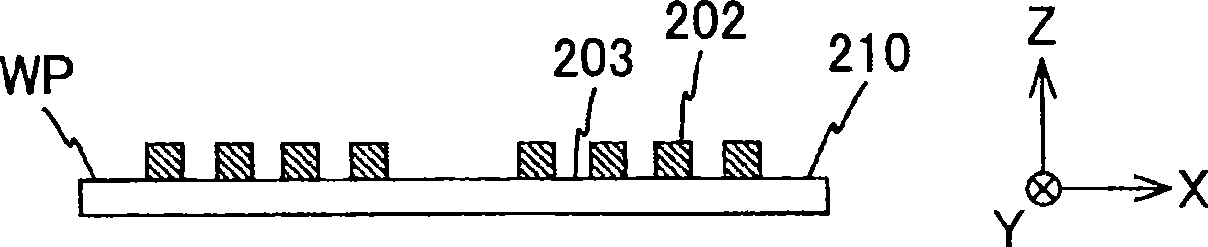

[0147] Figure 10 It is a flowchart showing a series of processes implemented by the main control device 70 in the irradiation device 10 when performing the astigmatism correction method according to the second embodiment of the present invention. In the following, the description is based on Figure 10 The astigmatism correction method of the illumination system within the illumination apparatus 10 is illustrated. suppose Figure 11 The reference sample WP shown is mounted on the rotating stage 31 of the drawing device 100, the x, y coordinate system with the origin at the center of the reference sample WP and the x', y' coordinate system rotated by 45 degrees relative to the x, y coord...

no. 3 example

[0167] Next, refer to Figures 17A to 18B A third embodiment of the present invention will be described. It should be noted that the same reference symbols are used for the same or equivalent components as those of the first and second embodiments, and descriptions of these components are omitted or reduced.

[0168] The difference between the aberration correction method of the third embodiment of the present invention and the aberration correction method of the above-mentioned second embodiment is that Figure 10 The focus adjustment process in step 201. Hereinafter, this focus adjustment method is described.

[0169] Here, since the positional relationship between the objective lens 19 and the turntable 31 is fixed, when the focusing position of the electron beam receiving the refractive power through the objective lens 19 is focused near the upper surface of the turntable 31, the The current value (hereinafter referred to as the DAC value) is defined as the reference DA...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com