Friction braking material and preparation method thereof

A technology for friction brake materials and friction performance, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as complicated process and long preparation time, and achieve the effects of simplifying process, reducing cost and shortening preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The preparation method of the friction brake material provided by the invention comprises mixing short carbon fiber, binder, silicon powder and graphite powder to obtain a mixture; molding the mixture to obtain a compact; and sintering the compact in an inert atmosphere .

[0016] The short carbon fiber, binder, silicon powder and graphite powder can be mixed by conventional mixing methods. In order to mix the various components more uniformly, preferably, the fiber, the binder, the silicon powder and the carbon powder are mixed in a mixer. The mixing temperature can be 10-40°C, preferably 20-30°C; the mixing time can be 1-40 minutes, preferably 3-25 minutes. During the mixing process, the various raw materials are mixed evenly, so that the short carbon fibers are evenly dispersed in the final material.

[0017] When mixing, based on 100 parts by weight of fiber, the amount of binder can be 20-300 parts by weight, preferably 50-250 parts by weight; the amount of silic...

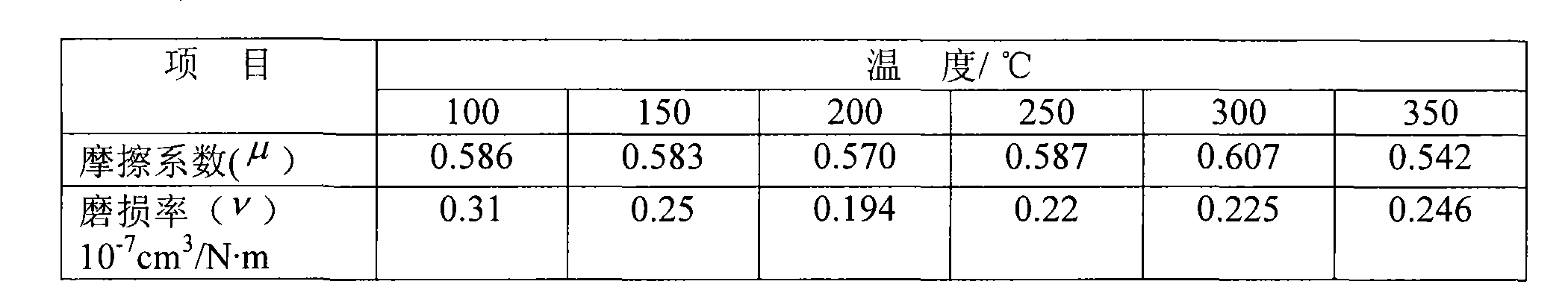

Embodiment 1

[0028] This embodiment is used to illustrate the friction brake material provided by the present invention and its preparation method.

[0029]100 parts by weight of polyacrylonitrile-based short carbon fibers (type T700, Changzhou Wujin Huadong Special Fiber Factory, with an average diameter of 6 microns and an average length of 10 cm), 200 parts by weight of modified phenolic resin (FB-2, Xi'an Taihang Fire-retardant Polymer Research Institute, particle size is 120 mesh), 300 parts by weight silicon powder (particle size is 120 mesh), 250 parts by weight graphite powder (Qingdao Tiansheng Graphite Co., Ltd., particle size is 120 mesh), 50 parts by weight silicon carbide ( Particle size is 160 mesh), 50 parts by weight of silicon dioxide (particle size is 160 mesh) and 50 parts by weight of silicon nitride (particle size is 120 mesh) in a mixer (JF810SJ plow rake mixer, Jilin University Institute of Mechanical and Electrical Equipment ) at 22° C. for 10 minutes to obtain a mi...

Embodiment 2

[0034] This embodiment is used to illustrate the friction brake material provided by the present invention and its preparation method.

[0035] 100 parts by weight of pitch-based carbon fiber (T300, Lanzhou Jintan Carbon Fiber Research Institute, with an average diameter of 8 microns and an average length of 7 cm), 60 parts by weight of phenolic resin (PF-6818, Yingkou Shengquan Haworth Chemical Co., Ltd. company, particle size is 160 mesh), 80 parts by weight of silicon powder (particle size is 160 mesh) and 100 parts by weight of graphite powder (Qingdao Tiansheng Graphite Co., Ltd., particle size is 160 mesh) in the mixer (JF810SJ rake type mixer , Jilin University Institute of Mechanical and Electrical Equipment) mixed at 30°C for 20 minutes to obtain a mixture.

[0036] The above mixture was pressed into a rough billet in a metal mold, and the pressing conditions included: pressing pressure of 20 MPa, pressing speed of 5 mm / min, pressing temperature of 30° C., and pressin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thermal diffusivity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com