Clostridium for synthesizing glutathion and construction method and use thereof

A technology of glutathione and clostridium, which is applied in the field of clostridium for the synthesis of glutathione and its construction and application, can solve the problem of strain production performance conversion rate, yield, production intensity and ability to withstand extreme environments that are difficult to meet industrial Production requirements and other issues, to achieve the effect of increasing butanol production intensity, improving downstream processing, and improving the ability to utilize starch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

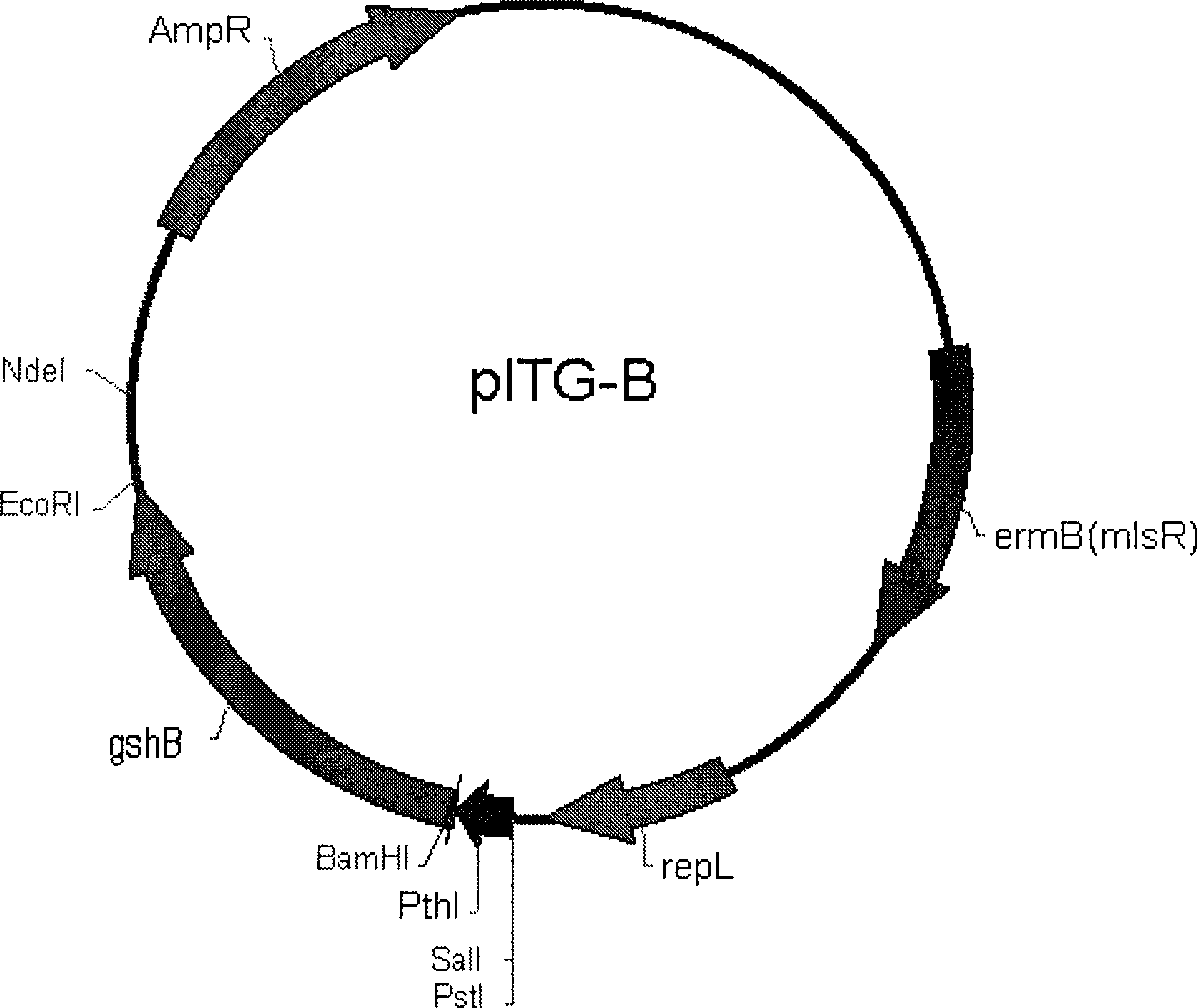

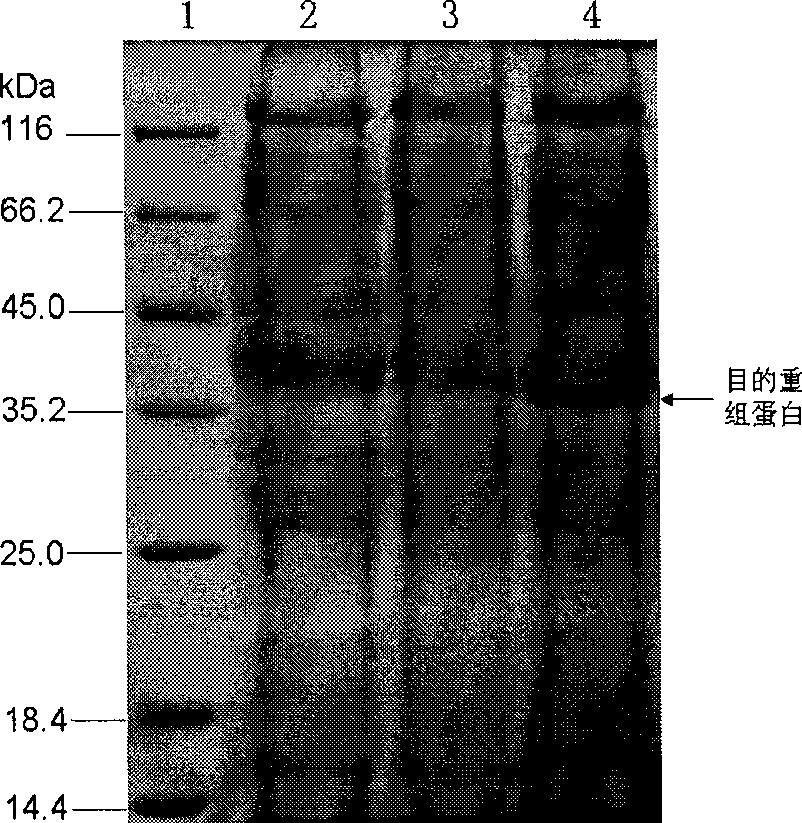

[0035] Embodiment 1, construct the clostridium acetobutylicum of synthetic glutathione

[0036] The bacterial genome extraction kit was used to extract the chromosomal DNA of E.coli JM109 in the middle and late stages of logarithmic growth, and use this as a template to perform PCR amplification with the following primers:

[0037] gshB-F:5'-ttcaga ggatcc ATGATCAAGCTCGGCATCGTG-3' (the chemical line part is BamH I recognition site);

[0038] gshB-R:5'-aaggc gaattc TTACTGCTGCTGTAAACGTGCTTC-3' (the underlined part is the EcoR I recognition site).

[0039] The high-efficiency fidelity enzyme Primerstart of TaKaRa Company was used for PCR amplification, and the PCR amplification program was: 95°C for 3min; 98°C for 10s, 55°C for 15s, 72°C for 1min, 30 cycles; 72°C for 10min.

[0040] The obtained PCR product was purified using a PCR product recovery kit, and then the purified PCR product was double-enzymatically digested with BamH I and EcoR I from Fermetas, and after standing...

Embodiment 2

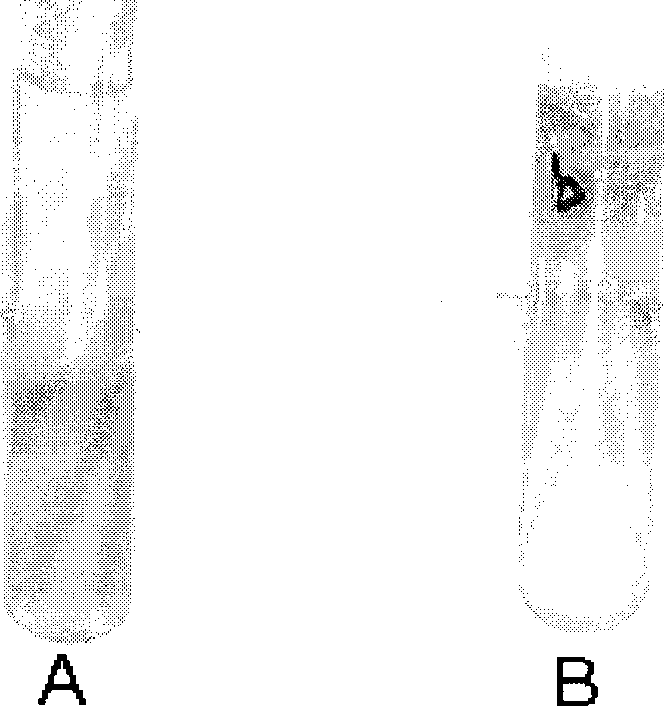

[0054] Embodiment 2, utilize Clostridium acetobutylicum (Clostridium acetobutylicum) SMB-1 (pITG-B) to produce butanol by fermentation

[0055] Clostridium acetobutylicum (Clostridium acetobutylicum) SMB-1 (pITG-B) was statically cultured in RCM medium at 37° C. to logarithmic phase, and used as fermentation seed solution 1.

[0056] The fermented seed liquid 1 was inoculated into a 7L fermenter equipped with 3L corn starch medium according to the volume percentage of 5% for fermentation. The fermentation temperature was 35°C, 37°C, and 39°C respectively, and the fermentation method was static fermentation; The time is 36 hours. Clostridium acetobutylicum (Clostridium acetobutylicum) SMB-1 (pIMP1) was used as a control. The fermented broth after fermentation was detected by liquid chromatography, and the results are shown in Table 1. Liquid chromatography detection condition is: sample pretreatment: 12000rpm centrifuges 1min, gets supernatant, filters with 0.22 μm filter mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com