Method for producing pyromelane type nano-TiO2 powder with Ti(SO4)2 hydrothemal method

A nano-powder, brookite-type technology, applied in the fields of photocatalysis and material chemistry, can solve the problems of difficulty in synthesis, neglect of structure and performance, and difficulty in preparing brookite-type TiO2, and achieve the effect of good photocatalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

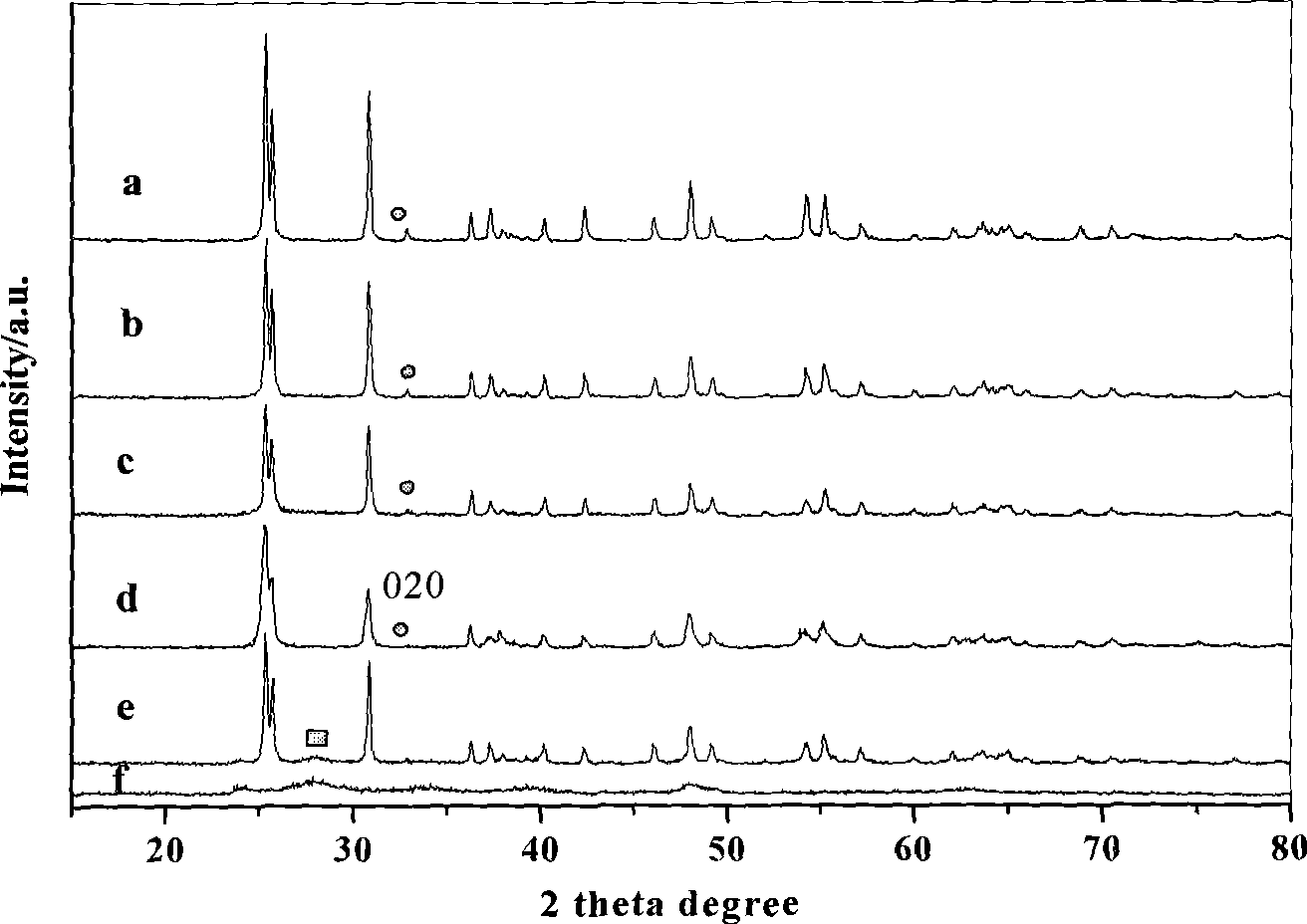

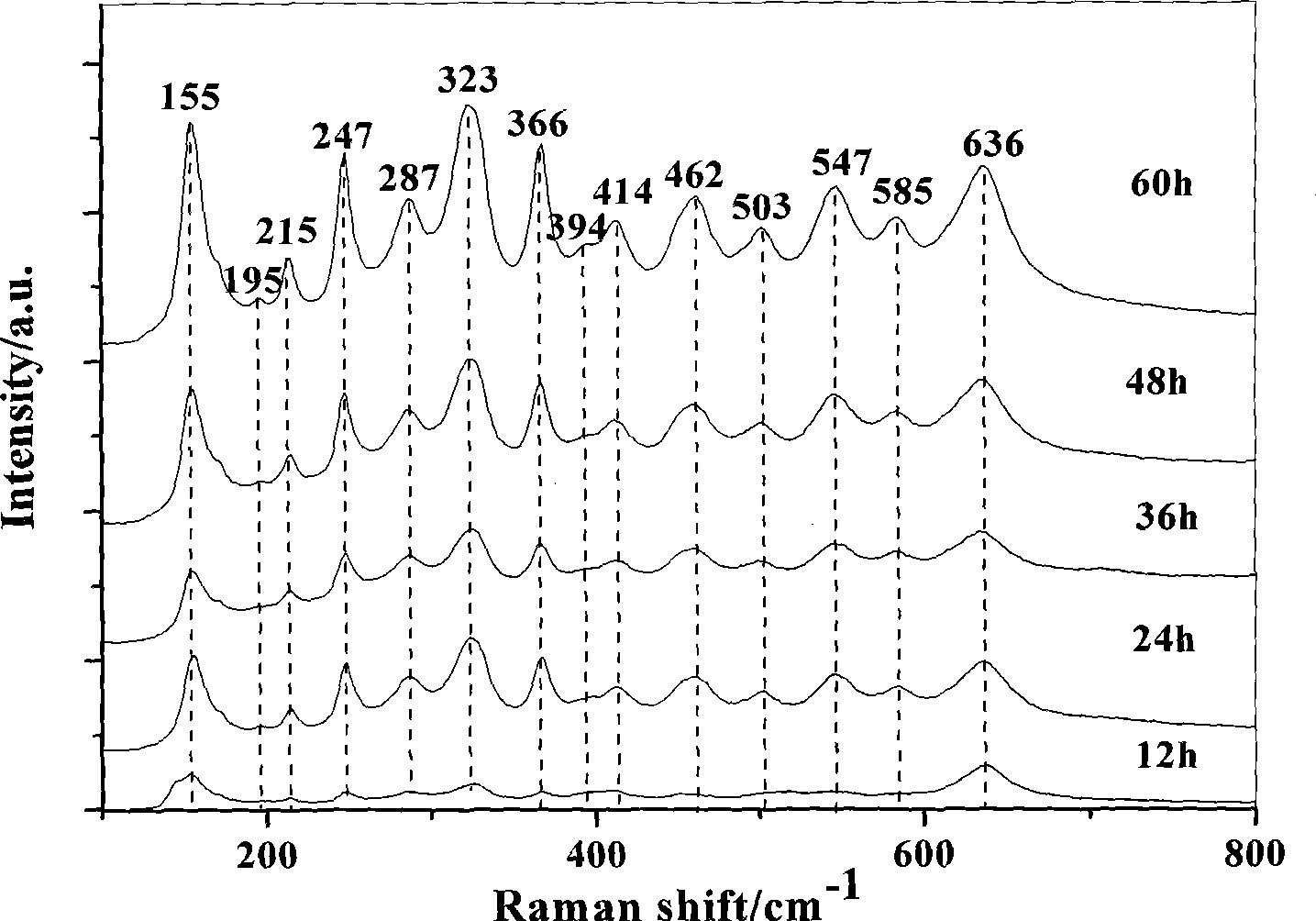

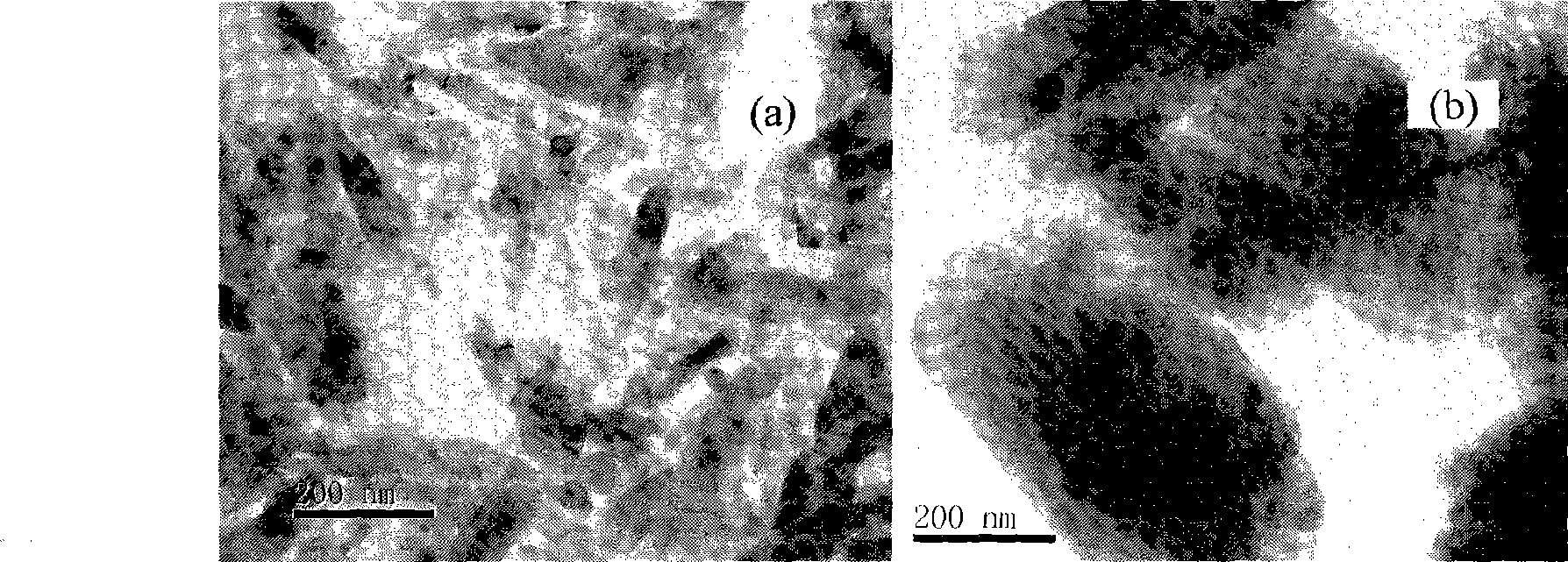

[0019] Take 1mol / L of Ti(SO 4 ) 2 Transfer 120 mL of the solution to a 500 mL beaker. During stirring with a magnetic stirrer at room temperature, 250 mL of a newly prepared 2 mol / L NaOH solution was added dropwise to the Ti(SO 4 ) 2 solution in a beaker. NaOH and Ti(SO 4 ) 2 The molar ratio of 5:1. During the titration process, a white precipitate was formed, and the stirring was continued for 5 hours, and it was allowed to stand overnight. washed several times by centrifugation, with BaCl 2 Solution test without SO 4 2- exists, and the solution pH=10.61 at this time. The precursor obtained from the above reaction was evenly transferred to six 100mL high-pressure hydrothermal reaction kettles marked with different serial numbers, and then placed in an electric constant temperature blast drying oven. The reaction kettle was taken out after 180°C hydrothermal reaction for different times, and the reaction kettle was taken out and cooled to room temperature naturally....

Embodiment 2

[0027] Take 1mol / L of Ti(SO 4 ) 2Transfer 120 mL of the solution to a 500 mL beaker. During stirring with a magnetic stirrer at room temperature, 200 mL of a newly prepared 2 mol / L NaOH solution was added dropwise to the Ti(SO 4 ) 2 solution in a beaker. NaOH and Ti(SO 4 ) 2 The molar ratio of 3:1. During the titration process, a white precipitate was formed, and the stirring was continued for 5 hours, and it was allowed to stand overnight. washed several times by centrifugation, with BaCl 2 Solution test without SO 4 2- exist. The precursor obtained from the above reaction was evenly transferred to six 100mL high-pressure hydrothermal reaction kettles marked with different serial numbers, and then placed in an electric constant temperature blast drying oven. The reaction kettle is taken out after 150°C hydrothermal reaction for different times, and the reaction kettle is naturally cooled to room temperature, washed, and the product is dried in an electric constant ...

Embodiment 3

[0029] Take 1mol / L of Ti(SO 4 ) 2 Transfer 120 mL of the solution to a 500 mL beaker. During stirring with a magnetic stirrer at room temperature, 250 mL of a newly prepared 2 mol / L NaOH solution was added dropwise to the Ti(SO 4 ) 2 solution in a beaker. NaOH and Ti(SO 4 ) 2 The molar ratio of 4:1. During the titration process, a white precipitate was formed, and the stirring was continued for 5 hours, and it was allowed to stand overnight. washed several times by centrifugation, with BaCl 2 Solution test without SO 4 2- exist. The precursor obtained from the above reaction was evenly transferred to six 100mL high-pressure hydrothermal reaction kettles marked with different serial numbers, and then placed in an electric constant temperature blast drying oven. The reaction kettle was taken out after being hydrothermally reacted at 180°C for different times. After taking out the reaction kettle, it was naturally cooled to room temperature, washed, and the product was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com