Process for producing spherical FeOOH nano-powder

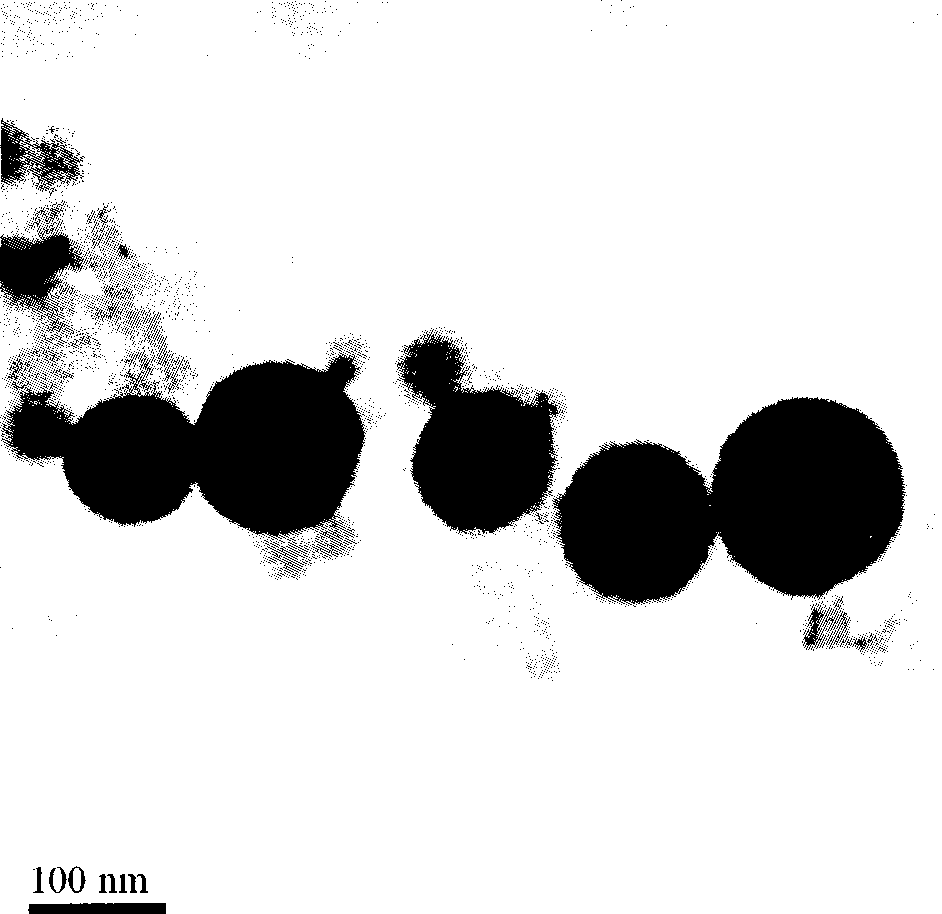

A nano-powder and spherical technology, which is applied in the field of preparation of spherical FeOOH nano-powder, can solve the problems of uneven average particle size, complex synthesis steps, and low purity of spherical powder, and achieve low cost, short reaction time, and high purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

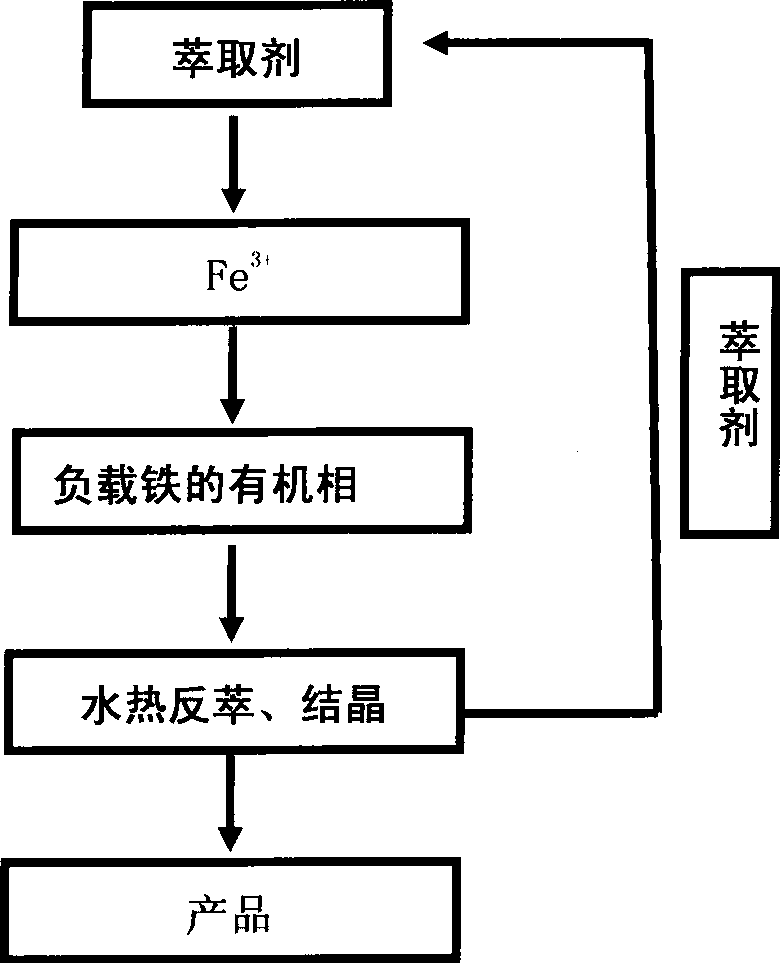

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of spherical FeOOH nanopowder, comprising the steps of:

[0026] (1) Under stirring, tributyl phosphate, isooctyl alcohol, kerosene and 0.2mol·L -1 Fe 3+ Mix the aqueous solution (choose ferric chloride aqueous solution to prepare), adjust pH=2.5, continue to stir after 0.5 hour, put the mixed solution in the liquid separation device, stand still for 10 minutes, separate the organic phase and the aqueous phase of loading metal iron, washing the organic phase loaded with metallic iron for 3 times with distilled water, and then separating the liquids to collect the organic phase loaded with metallic iron;

[0027] (2) The organic phase loaded with metallic iron and the aqueous ammonia solution with pH=8 are uniformly mixed in a volume ratio of 1:1 and then introduced into a high-pressure axe, at a stirring rate of 500 rpm and a temperature of 130°C, The pressure is 0.5Mpa, and the hydrothermal stripping reaction is carried out for 30 minutes;

[00...

Embodiment 2

[0031] A preparation method of spherical FeOOH nanopowder, comprising the steps of:

[0032] (1) Under stirring, tributyl phosphate, B liquid and 0.05mol·L -1 Fe 3+ Mix the aqueous solution (choose ferric chloride aqueous solution to prepare), adjust pH=3.0, continue to stir for 0.5 hour, put into the separatory device, stand still for 60 minutes, separate the organic phase and the aqueous phase loaded with metal iron, wash with distilled water Describe the organic phase loaded with metallic iron for 2 times, then separate liquids, collect the organic phase loaded with metallic iron, and the B liquid is isooctyl alcohol and kerosene with a volume ratio of 1:3;

[0033] (2) Mix the organic phase loaded with metallic iron and ammonia water with pH=7 in a ratio of 1:1 by volume and then introduce it into a high-pressure axe. 4.0Mpa, carry out hydrothermal stripping reaction for 60 minutes;

[0034] (3) Naturally cool the reaction system to 20° C., turn on the high-pressure axe...

Embodiment 3

[0037] A preparation method of spherical FeOOH nanopowder, comprising the steps of:

[0038] (1) Under stirring, di(2-ethylhexyl)phosphoric acid, liquid B and 1.0mol·L -1 Fe 3+ Mix the aqueous solution (select ferric nitrate aqueous solution to prepare), adjust pH=0, continue to stir for 1.0 hour, put into the separatory device, stand still for 40 minutes, separate the organic phase and aqueous phase of loading metal iron, wash described loading with distilled water The organic phase of metallic iron was separated for 3 times, and the organic phase loaded with metallic iron was collected. The B liquid was isooctyl alcohol and kerosene with a volume ratio of 1:1;

[0039] (2) The organic phase loaded with metallic iron and the potassium hydroxide aqueous solution of pH=10 are uniformly mixed in a ratio of 4:1 by volume and then introduced into the high-pressure axe. °C, the pressure is 4.0Mpa, and the hydrothermal stripping reaction is carried out for 30 minutes;

[0040] (3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com