High-emperature highly saturated flux density MnZn ferrite material and method for producing magnetic core

A technology of ferrite materials and magnetic cores, applied in the field of soft ferrite materials, can solve the problems of high temperature of magnetic parts, high power consumption of magnetic cores, and reduced energy transmission efficiency, and achieve high saturation magnetic flux density performance and guarantee normal working effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

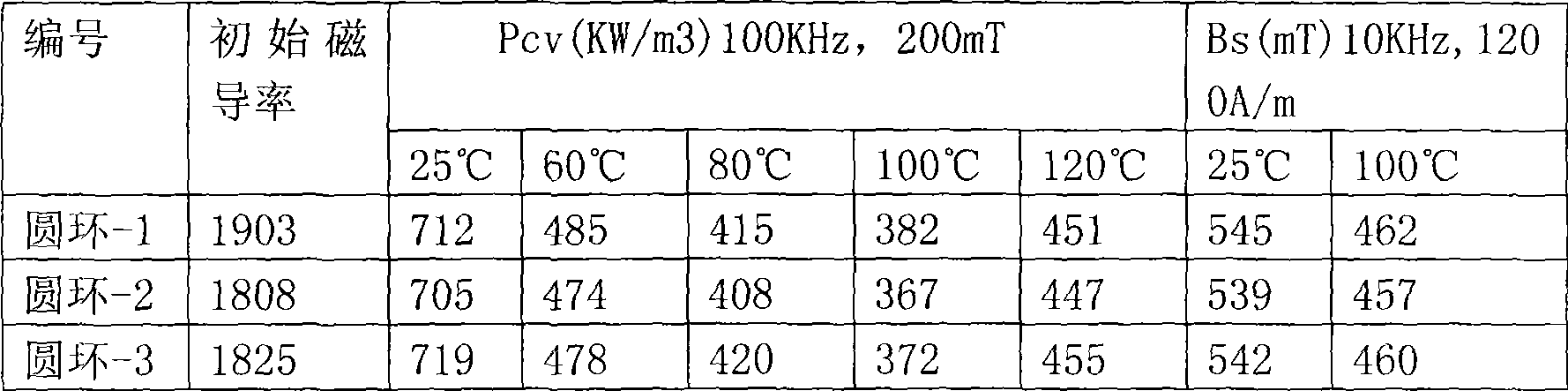

Embodiment 1

[0018] A method for preparing a magnetic core from a MnZn ferrite material includes the steps of primary batching and ball milling, pre-sintering, secondary batching and ball milling, spray granulation to obtain pellets, pressing into a green body, and green body sintering. The main ingredient is iron oxide Fe 2 O 3 50.2mol%, manganese oxide MnO47.9mol%, the balance is zinc oxide ZnO, of which Fe 2 O 3 Using German ThyssenKrupp iron red (purity ≥99.3wt%), MnO is converted into Mn 3 O 4 , Using high-purity Mn from Hunan Jinrui 3 O 4 (Purity≥98.8wt%), ZnO from Haimen, Zhejiang (purity≥99.7wt%) is used for ZnO. Pour the three raw materials into a mixing tank, add dispersant and deionized water, stir and mix thoroughly, and perform ball milling for 3-6 hours. Spray drying and calcination are performed, the calcination temperature is 760-950°C, the calcination time is 40-90 minutes, and the calcination material is obtained. In the main crystalline phase, 100-800 ppm by weight of the fi...

Embodiment 2

[0020]A method for preparing a magnetic core from a MnZn ferrite material includes the steps of primary batching and ball milling, pre-sintering, secondary batching and ball milling, spray granulation to obtain pellets, pressing into a green body, and green body sintering. In the main ingredient, iron oxide Fe is added 2 O 3 55.3mol%, manganese oxide MnO 38.4%, the balance is zinc oxide ZnO, of which Fe 2 O 3 Using German ThyssenKrupp iron red (purity ≥99.3wt%), MnO is converted into Mn 3 O 4 , Using high-purity Mn from Hunan Jinrui 3 O 4 (Purity≥98.8wt%), ZnO from Haimen, Zhejiang (purity≥99.7wt%) is used for ZnO. Pour the three raw materials into a stirring tank, add dispersant and deionized water, stir and mix thoroughly, and perform ball milling for 3-6 hours. Spray drying and calcination are performed, the calcination temperature is 760-950°C, the calcination time is 40-90 minutes, and the calcination material is obtained. In the main crystalline phase, 100-800 ppm by weight ...

Embodiment 3

[0022] A method for preparing a magnetic core from a MnZn ferrite material includes the steps of primary batching and ball milling, pre-sintering, secondary batching and ball milling, spray granulation to obtain pellets, pressing into a green body, and green body sintering. In the ingredients, the main ingredient is iron oxide Fe 2 O 3 52.7mol%, manganese oxide MnO 43.5mol%, the balance is zinc oxide ZnO, of which Fe 2 O 3 Using German ThyssenKrupp iron red (purity ≥99.3wt%), MnO is converted into Mn 3 O 4 , Using high-purity Mn from Hunan Jinrui 3 O 4 (Purity≥98.8wt%), ZnO from Haimen, Zhejiang (purity≥99.7wt%) is used for ZnO. Pour the three raw materials into a stirring tank, add dispersant and deionized water, stir and mix thoroughly, and perform ball milling for 3-6 hours. Spray drying and calcination are performed, the calcination temperature is 760-950°C, the calcination time is 40-90 minutes, and the calcination material is obtained. In the main crystalline phase, 100-800 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com