Chinese herbal medicine immunity enhancement type compound feed for Litopenaeus vannamei

A technology of immune enhancement and compound feed, applied in animal feed, animal feed, food science, etc., to achieve the effect of reducing disease occurrence, reducing use, and improving immune disease resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

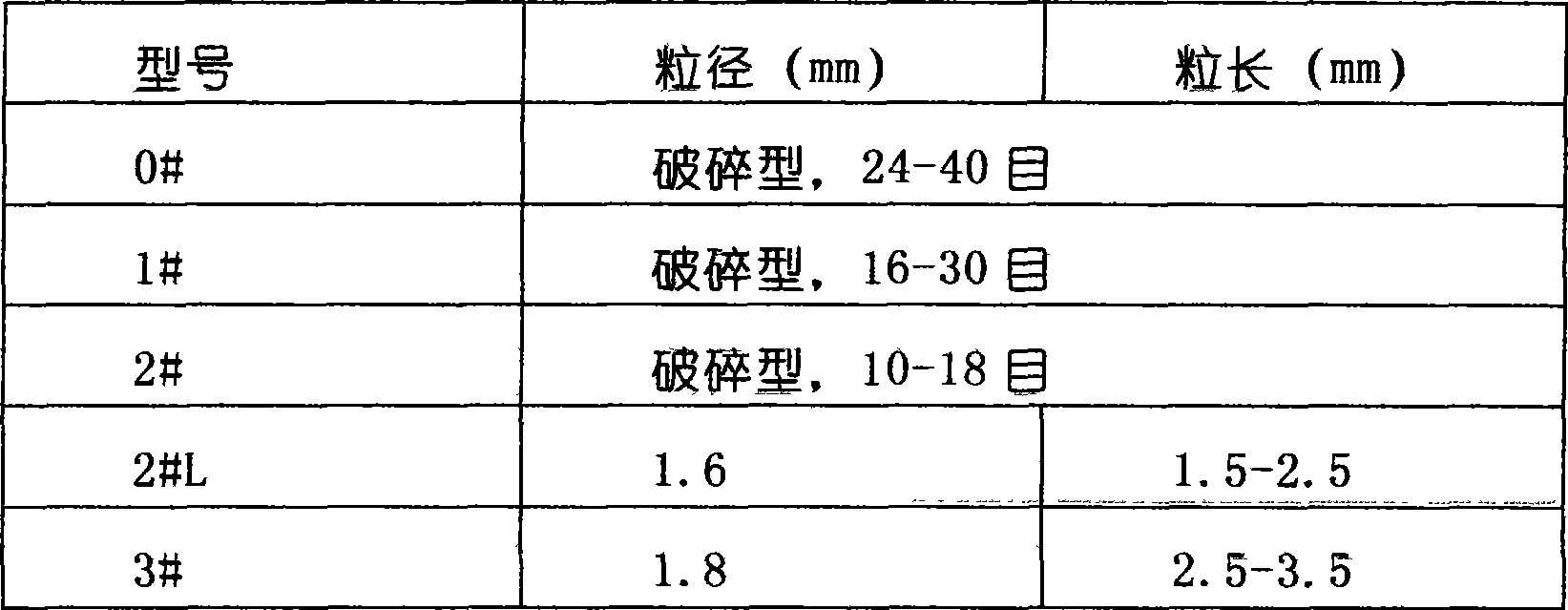

[0019] Embodiment one: produce vannamei compound feed 1#

[0020] Taking 100kg of raw materials to produce compound feed as an example, the weights (kg) of each raw material are:

[0021] Fish meal 35, brewer's yeast 2, corn gluten meal 3, shrimp shell powder 3, blood meal 2, squid paste 3, soybean meal 10, peanut cake 12, flour 23, kelp powder 2, soybean lecithin oil 2, fish oil 1, vannamei shrimp Mixture 2.

[0022] Processing technology: Mix the flour and various raw materials except the vannamei premix until the coefficient of variation C.V. of the mixing uniformity C.V. Proportionally add flour and Penaeus vannamei premix and mix again until the coefficient of variation C.V.<7.5% of the mixing uniformity; the mixture is tempered, the steam pressure of tempering is 0.25Mpa, the tempering temperature is 95°C, and the moisture content of the material The content is 16%, and the material after quenching and tempering is granulated by a hard pellet machine with a ring die of...

Embodiment 2

[0023] Embodiment two: produce vannamei compound feed 2#L

[0024] Taking 100kg of raw materials to produce compound feed as an example, the weights (kg) of each raw material are:

[0025] Fish meal 32, brewer's yeast 2, corn gluten meal 3, shrimp shell powder 3, blood meal 2, squid paste 3, soybean meal 11, peanut cake 13, flour 23, kelp powder 2, soybean lecithin oil 3, fish oil 1, vannamei shrimp Mixture 2.

[0026] Processing technology: Mix the flour and various raw materials except the vannamei premix until the coefficient of variation C.V. of the mixing uniformity C.V. Proportionally add flour and vannamei premix and mix again until the coefficient of variation of mixing uniformity C.V.<7.5%; the mixture is tempered, the steam pressure of tempering is 0.25Mpa, the tempering temperature is 90°C, and the moisture content of the material The content is 16%, and the material after quenching and tempering is granulated by a hard pellet machine with a ring die of 1.6mm; the...

Embodiment 3

[0027] Embodiment three: produce vannamei compound feed 3#

[0028] Taking 100kg of raw materials to produce compound feed as an example, the weights (kg) of each raw material are:

[0029] Fish meal 30, brewer's yeast 2, corn gluten meal 3, shrimp shell powder 3, blood meal 2, squid paste 3, soybean meal 12, peanut cake 13, flour 23, kelp powder 2, soybean lecithin oil 3, fish oil 2, vannamei shrimp Mixture 2.

[0030] Processing technology: Mix the flour and various raw materials except for the vannamei premix until the coefficient of variation C.V. of mixing uniformity <10%, and then pulverize, so that the fineness of the raw materials can reach more than 98% and pass through a 60-mesh standard sieve; Proportionally add flour and vannamei premix and mix again until the coefficient of variation of mixing uniformity C.V.<7.5%; the mixture is tempered, the steam pressure of tempering is 0.25Mpa, the tempering temperature is 90°C, and the moisture content of the material The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com