Technique for producing hot rolling hot forming T type channel steel with teeth

A production process and thermoforming technology, applied in the direction of metal rolling, etc., can solve the problems of reducing product gravity and tensile load, uneven structure, high cost, etc., and achieve the effect of ensuring safety, high gravity and tensile load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

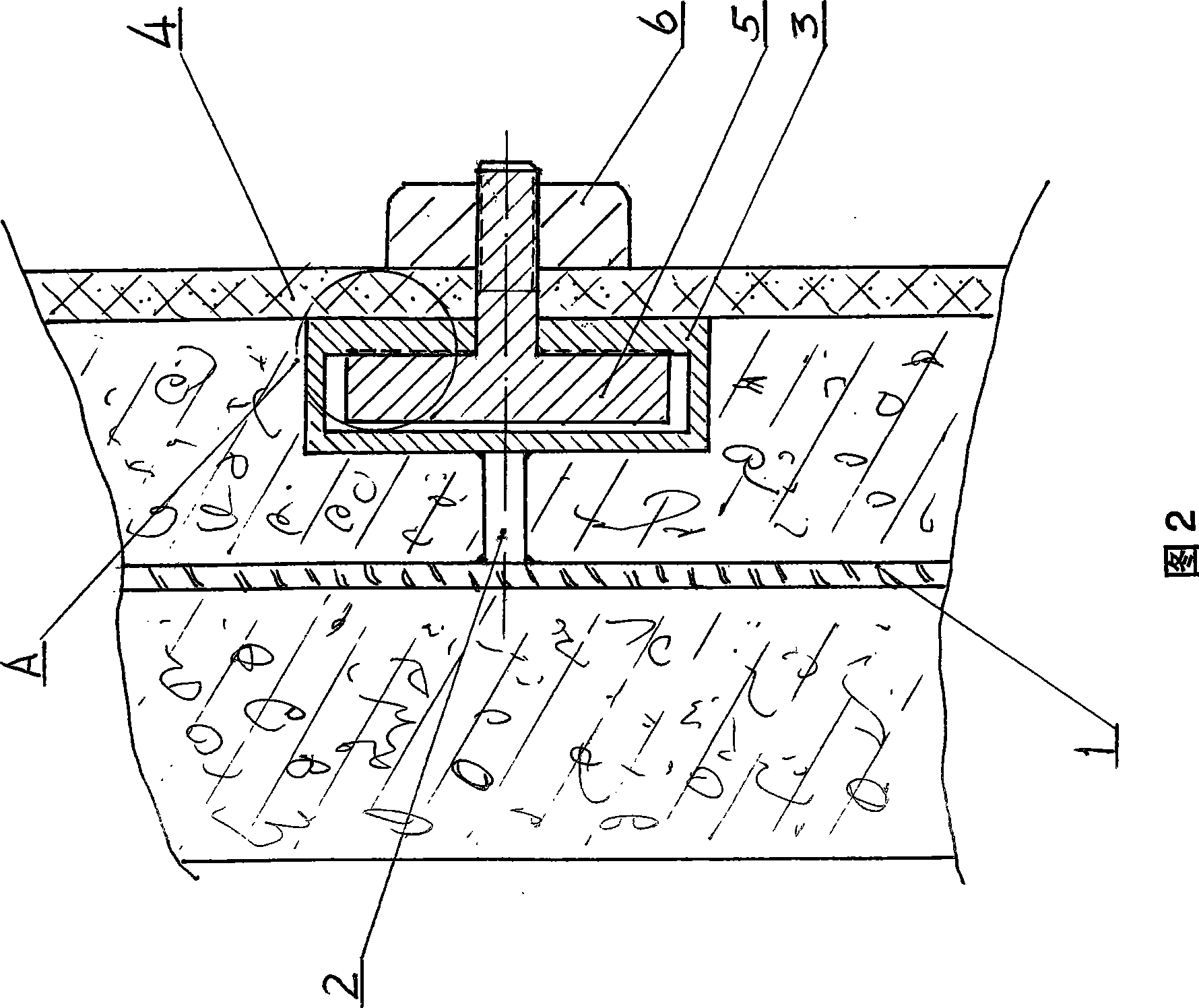

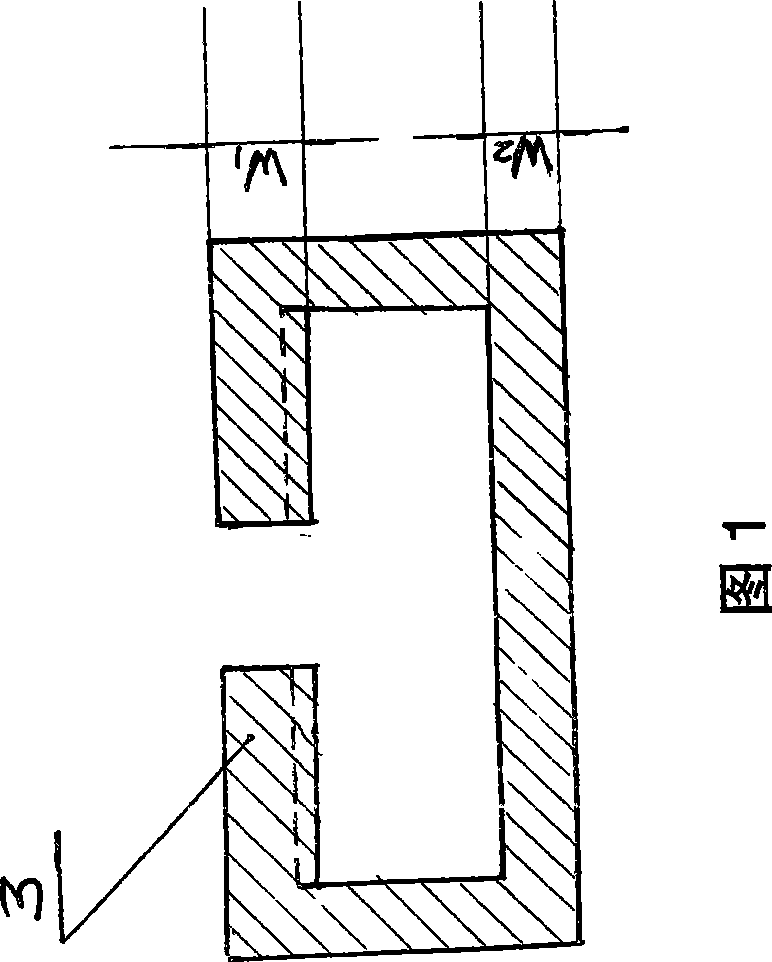

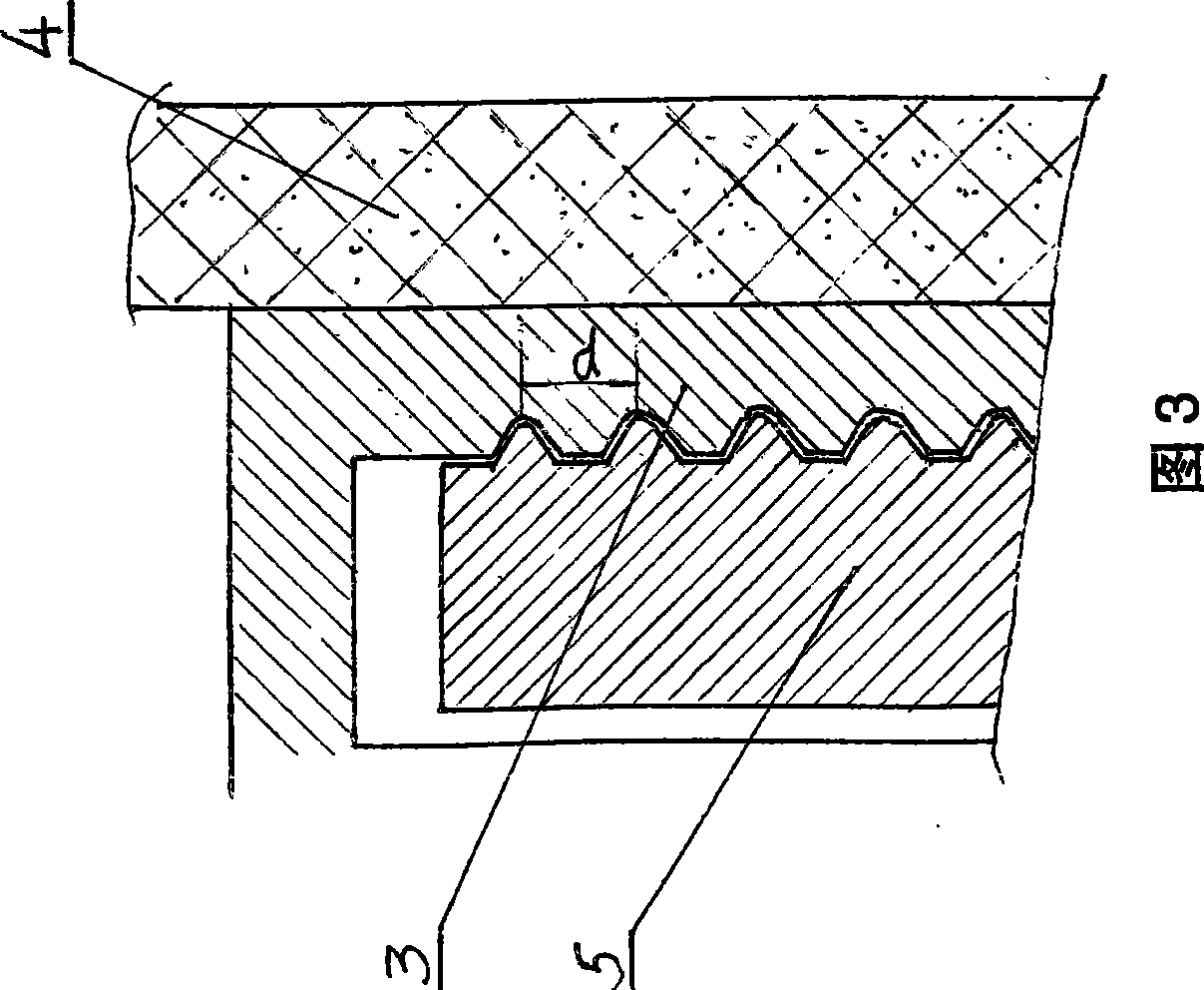

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0023] The material of the hot-rolled and hot-formed toothed T-channel steel can be selected from Q235 steel, which is ordinary carbon steel. On the oxygen top-bottom compound blowing converter, it is smelted according to the conventional method, and the ordinary continuous casting machine is continuously casted into a 75 square billet. As shown in Figure 6, the 75 square billet is heated in the steel rolling heating furnace 7 under the condition of 1200-1250°C, which is suitable for rolling. The heated 75 square billet is passed through 8 rolling mills for nine passes, and the corresponding roll passes are K20, K19, K18, K17, K16, K15, K14, K13 and K12. The arc-shaped billet rolled out from the ninth pass of the blooming mill 8, that is, the last pass (pass type K12), is sent to the middle rolling mill 9 for one pass e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com