Processing system and operation method for phosphor-containing organic wastewater

A technology of organic wastewater and operation method, which is applied in water/sewage treatment, biological water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of not being able to guarantee discharge up to the standard, and reduce operating costs and dosage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

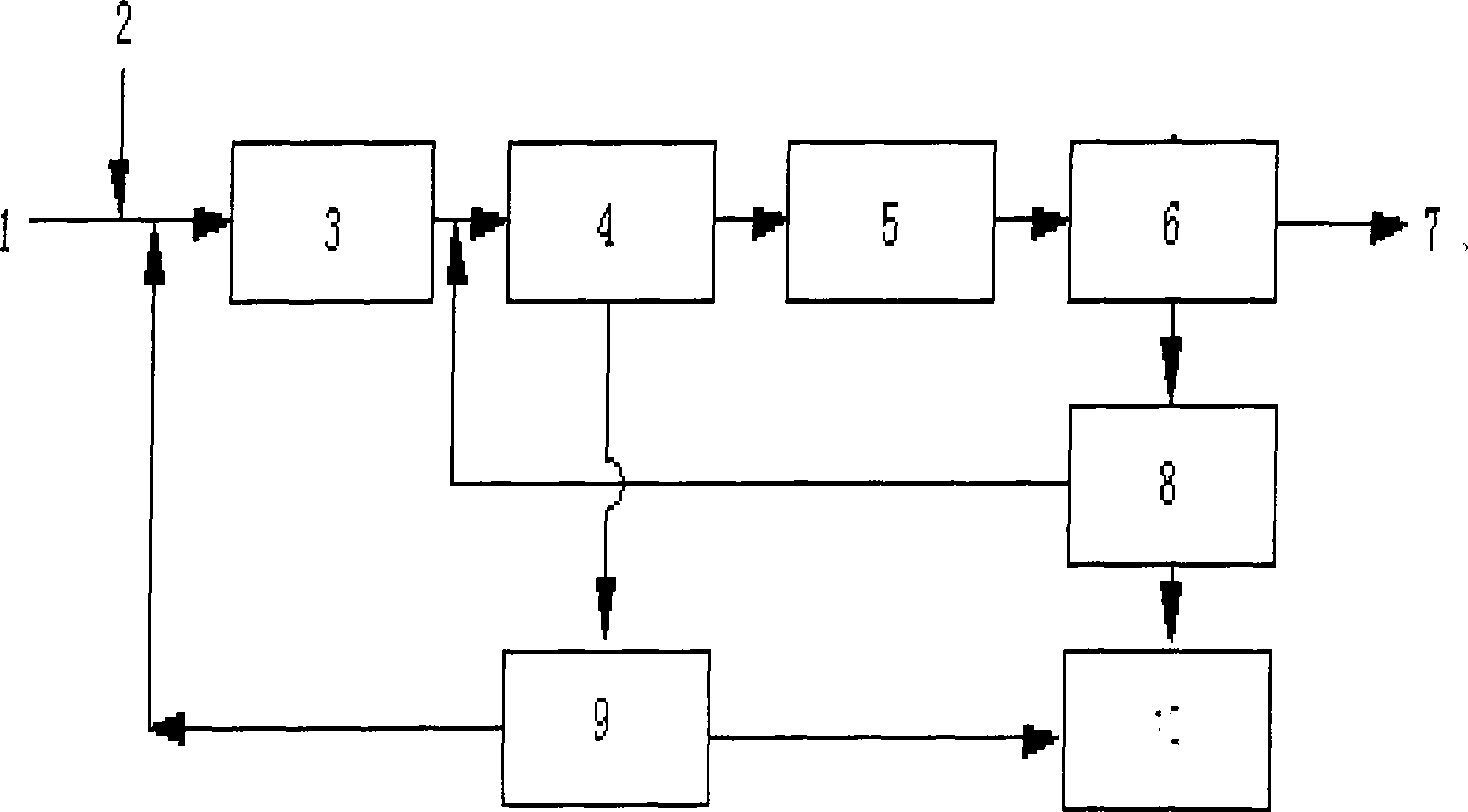

[0028] The water quality of phosphorus-containing organic wastewater 1 COD≥500mg / L, BOD 5 ≥300mg / L, TP≥18mg / L, it enters the mixing reactor 3 (hydraulic retention time 20min), and the FeCl 3(dosing amount 90mg / L) iron salt 2, the mud slag that returns from sludge tank 9 fully mixes, and the phosphorus in the waste water and iron salt generation chemical reaction generates the insoluble sediment of phosphorus, and precipitation is poisonous to aerobic microorganism simultaneously sulfide. Then, the wastewater and sediment discharged from the mixing reactor 3 are mixed with the excess sludge returned from the excess sludge conditioning tank 8, and flow into the sedimentation tank 4 (hydraulic retention time 2.0h) together for sludge-water separation.

[0029] The waste water after chemical phosphorus removal from the sedimentation tank 4 enters the contact oxidation tank 5 (hydraulic retention time 4.5h), where a part of the organic matter is oxidized and degraded into carbon d...

Embodiment 2

[0033] The water quality of phosphorus-containing organic wastewater 1 COD≥2500mg / L, BOD 5 ≥1350mg / L, TP≥33mg / L, it enters the mixing reactor 3 (hydraulic retention time 30min), and the FeCl 3 (dosing amount 180mg / L) iron salt 2, the mud slag that returns from sludge tank 9 fully mixes, and the phosphorus in the waste water and iron salt generation chemical reaction generates the insoluble sediment of phosphorus, and precipitation is poisonous to aerobic microorganism at the same time sulfide. Then, the wastewater and sediment discharged from the mixing reactor 3 are mixed with the excess sludge returned from the excess sludge conditioning tank 8, and flow into the sedimentation tank 4 (hydraulic retention time 3.0h) together for sludge-water separation.

[0034] The waste water after chemical phosphorus removal from the sedimentation tank 4 enters the contact oxidation tank 5 (hydraulic retention time 6.5h), where a part of the organic matter is oxidized and degraded into ca...

Embodiment 3

[0038] The water quality of phosphorus-containing organic wastewater 1 COD≥5000mg / L, BOD 5 ≥3000mg / L, TP≥70mg / L, it enters the mixing reactor 3 (hydraulic retention time 40min), and the FeCl 3 (dosing amount 400mg / L) iron salt 2, the mud slag that returns from sludge tank 9 fully mixes, and the phosphorus in the waste water and iron salt generation chemical reaction generates the insoluble sediment of phosphorus, and precipitation is poisonous to aerobic microorganism simultaneously sulfide. Then, the wastewater and sediment discharged from the mixing reactor 3 are mixed with the excess sludge returned from the excess sludge conditioning tank 8, and flow into the sedimentation tank 4 (hydraulic retention time 4.0h) together for sludge-water separation.

[0039] The wastewater after chemical phosphorus removal from the sedimentation tank 4 enters the contact oxidation tank 5 (hydraulic retention time 9.0 h), where a part of the organic matter is oxidized and degraded into carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com