Lithium ion battery cathode and preparation method thereof and lithium ion battery

A lithium-ion battery, negative electrode technology, applied in battery electrodes, electrode manufacturing, secondary batteries and other directions, can solve the problems of internal short circuit, poor battery cycle performance, battery short circuit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

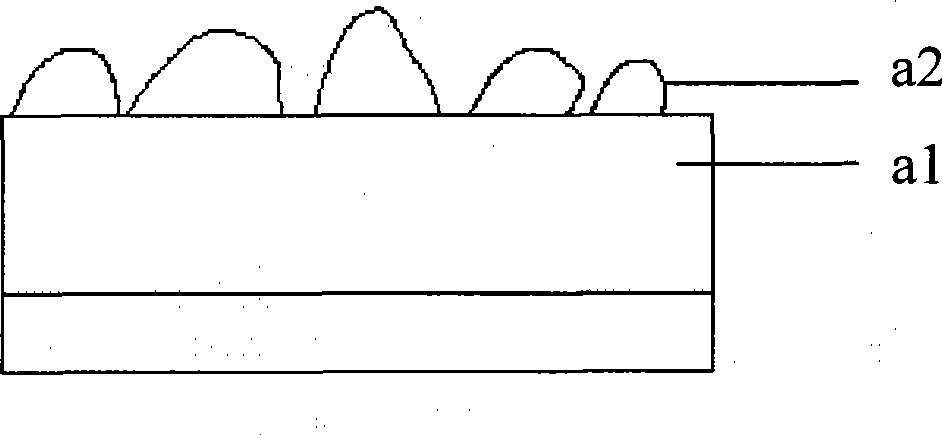

[0020] The preparation method of the lithium ion battery negative electrode provided by the present invention comprises that the slurry containing the negative electrode material is continuously loaded on the negative electrode current collector, and then dried to form a continuous layer on the negative electrode current collector; the slurry containing the negative electrode material is loaded at intervals on the continuous layer, followed by drying to form a discontinuous layer on the continuous layer; and then rolling to obtain a negative electrode.

[0021] The negative electrode collector may be a conventional negative electrode collector in lithium ion batteries, for example, copper foil may be used as the negative electrode collector.

[0022] The slurry containing the negative electrode material can be continuously supported on the negative electrode current collector by conventional methods, for example, various existing coating methods for preparing lithium ion batter...

Embodiment 1

[0038] This example is used to illustrate the preparation of the lithium ion battery negative electrode of the present invention.

[0039] (1) After mixing 30 grams of micron-sized silicon powder (purity 99.99%) and 60 grams of micron-sized conductive copper powder (purity 90%) as the negative electrode active material, add to the solution containing 10 grams of polyvinylidene fluoride (PVDF) In a solution of 200 g of N-methylpyrrolidone (NMP) of the binder, stir evenly under a dry atmosphere to prepare negative electrode slurry.

[0040] (2) Coating the negative electrode slurry obtained in step (1) on the rough electrolytic copper foil current collector, the coating thickness is 80 microns.

[0041] (3) After the pole piece is dried, place it on the vacuum adsorption platform of the screen printing machine, and cover the screen printing plate (100 mesh nylon mesh, the thickness of the screen printing plate is 80 microns) on the coated continuous layer On, the slurry obtaine...

Embodiment 2

[0044] This example is used to illustrate the preparation of the lithium ion battery negative electrode of the present invention.

[0045] (1) 90 grams of micron-sized tin dioxide powder (purity 90%) as the negative electrode active material are added to 200 grams of N-methylpyrrolidone (NMP) dissolved in 10 grams of polyvinylidene fluoride (PVDF) binder solution, stirred evenly under a dry atmosphere to prepare negative electrode slurry.

[0046] (2) Coating the slurry obtained in step (1) on the rough electrolytic copper foil current collector with a coating thickness of 100 microns.

[0047] (3) Using the same method as in step (3) of Example 1, the difference is that the thickness of the discontinuous layer is 40 microns, and the coverage is 32%.

[0048] (4) Calendering after drying, so that the thickness of the continuous layer is 50 microns, and the thickness of the discontinuous layer is 20 microns, and the product is designated as A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com