Electrochemical energy storage device with high capacity and high power using conductive polymer composite

一种导电性聚合物、导电性的技术,应用在使用导电性聚合物复合材料的具有高容量和高功率的电化学贮能装置领域,能够解决电化学装置高容量、降低内电阻、高输出量等问题,达到提高简易性和成本效益的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

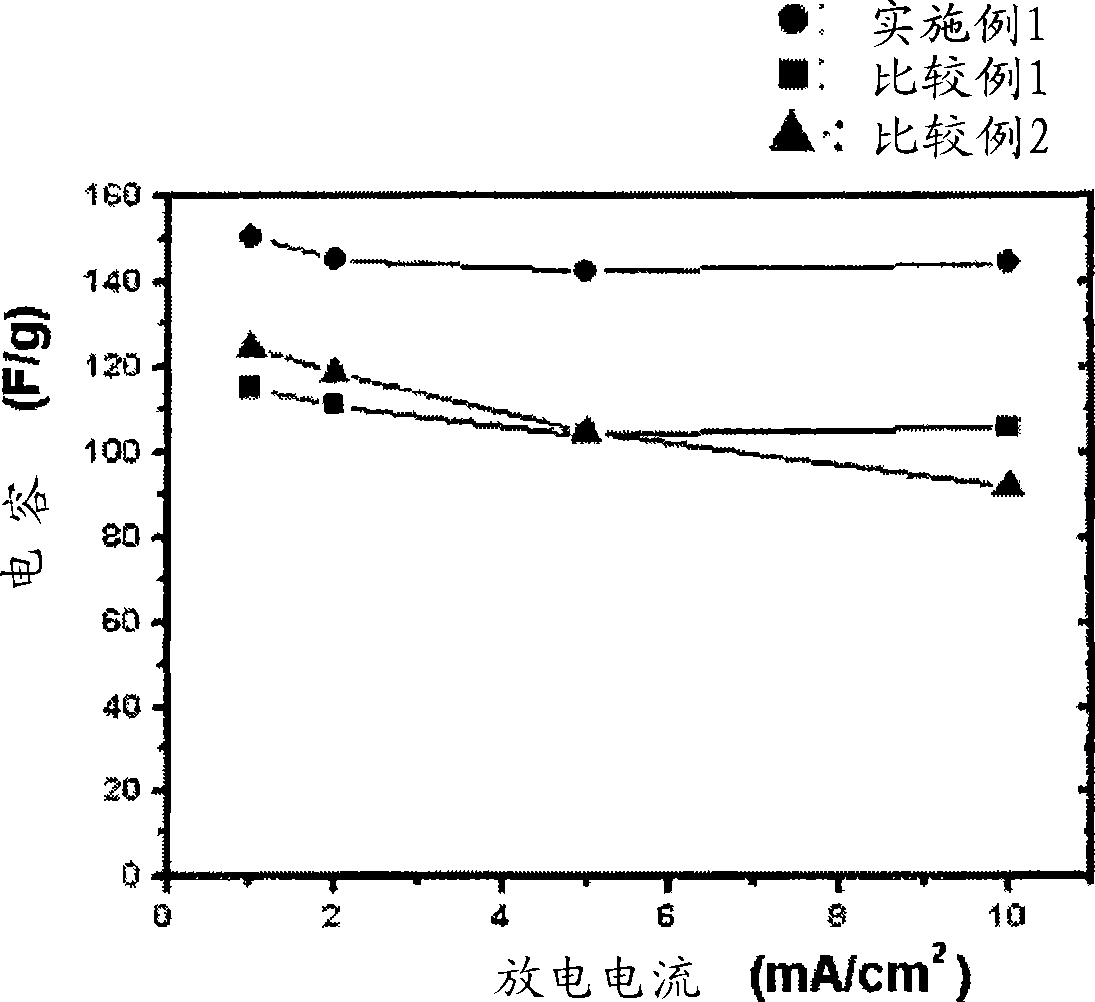

Embodiment 1

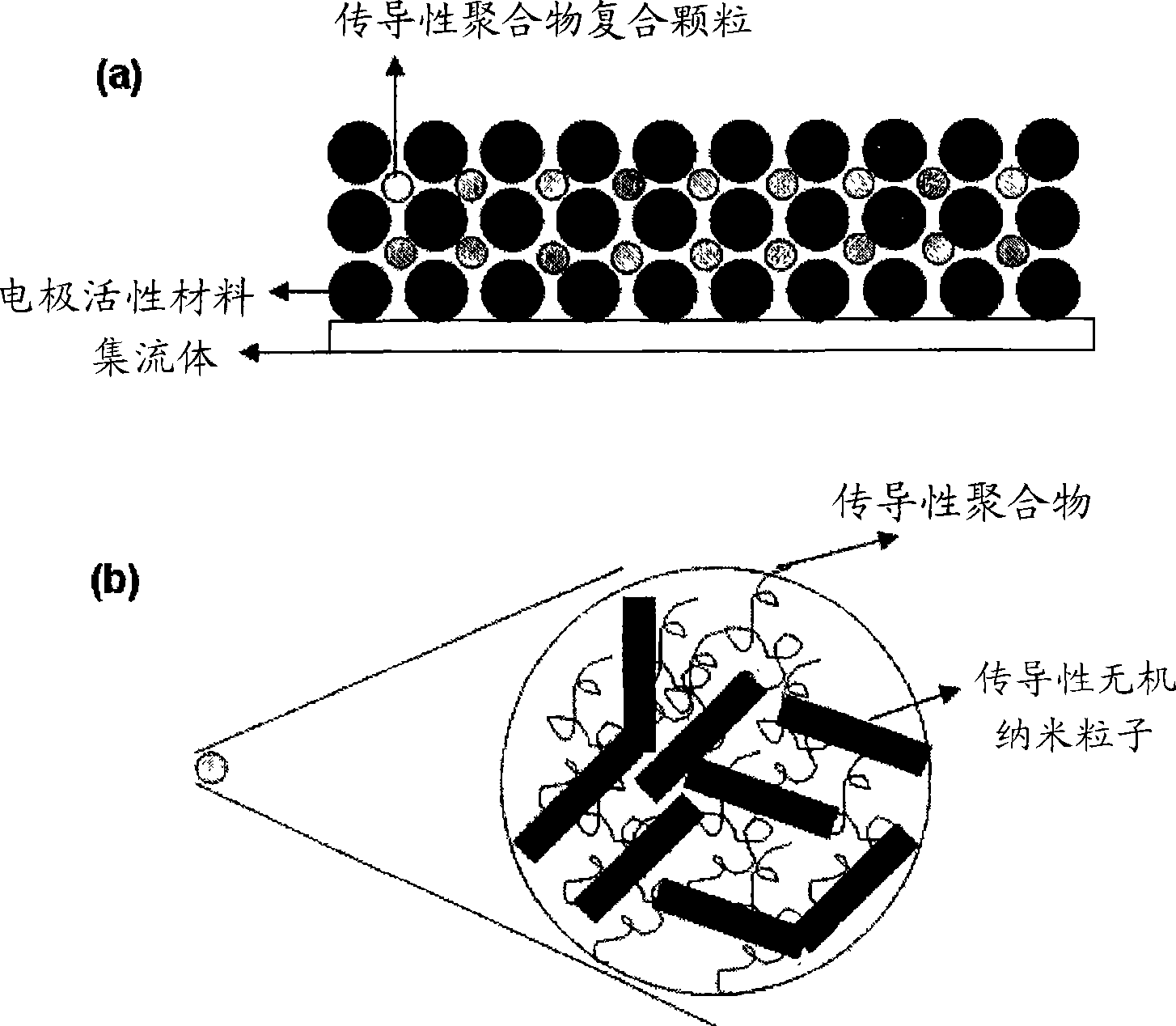

[0064] 1-1. Preparation of composite particles (conductive carbon / conductive polymer)

[0065] To an aqueous solution of a conductive polymer PEDOT, 2% by weight of carbon nanotubes (thickness: 20 nm, length: 5 μm) was dispersed and the resulting solution was adjusted to have an acidity of pH 3 to improve dispersibility. The homogeneously mixed PEDOT / carbon nanotube slurry is concentrated and dried to obtain a PEDOT / carbon nanotube composite material. The final composite particles have a diameter of 500 nm.

[0066] 1-2. Electrode preparation

[0067]To distilled water as a solvent, add 85% by weight of activated carbon (MSP20, Kansai Coke and Chemicals Co., Ltd.) as an electrode active material, 5% by weight of Super-P (carbon black) spherical particles with a particle diameter of 500 nm , 5% by weight of PTFE as a non-conductive binder, and 5% by weight of the PEDOT / CNT composite particles obtained as described in Example 1-1, to obtain a mixture of five components as ...

Embodiment 2

[0071] An electric double layer capacitor was provided in the same manner as described in Example 1, except that 95% by weight of activated carbon was used as the electrode active material and 5% by weight of the PEDOT / CNT composite material prepared in Example 1 was used to provide the electrodes . The capacitor obtained in this Example 2 exhibited qualities similar to the capacitor of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com