Earlier stage treatment process of raw material powder for preparing induction plasma capacitor level nano tantalum powder

A pre-treatment and plasma technology, which is applied in the pre-treatment process field of raw material powder for the preparation of induction plasma capacitor grade nano-tantalum powder, can solve the problem of low energy utilization rate of the preparation process, low material utilization rate, and will not increase the specific capacity of the capacitor , low collection rate of nano-tantalum powder, etc., to achieve the effect of improving energy utilization rate and material utilization rate, improving fluidity and improving distribution state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

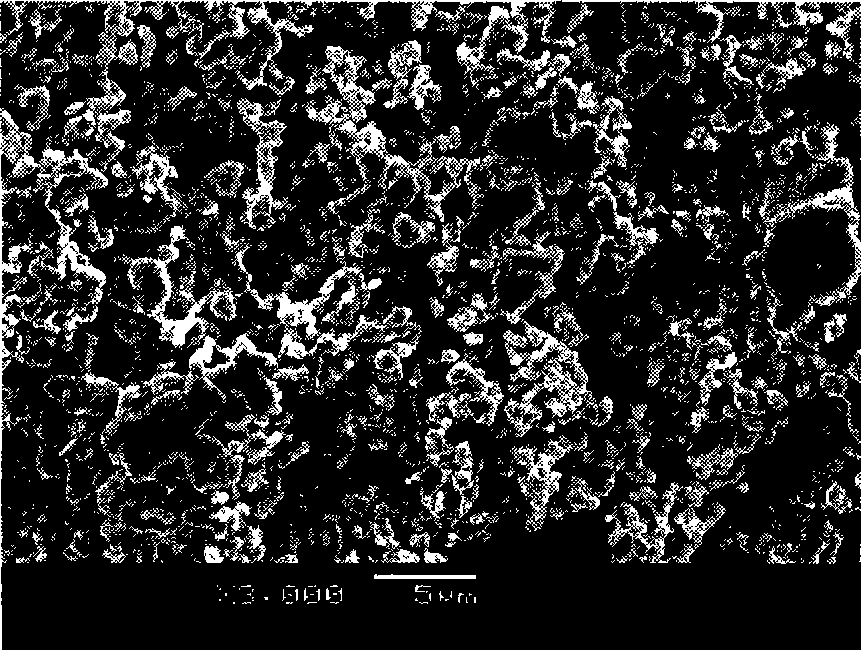

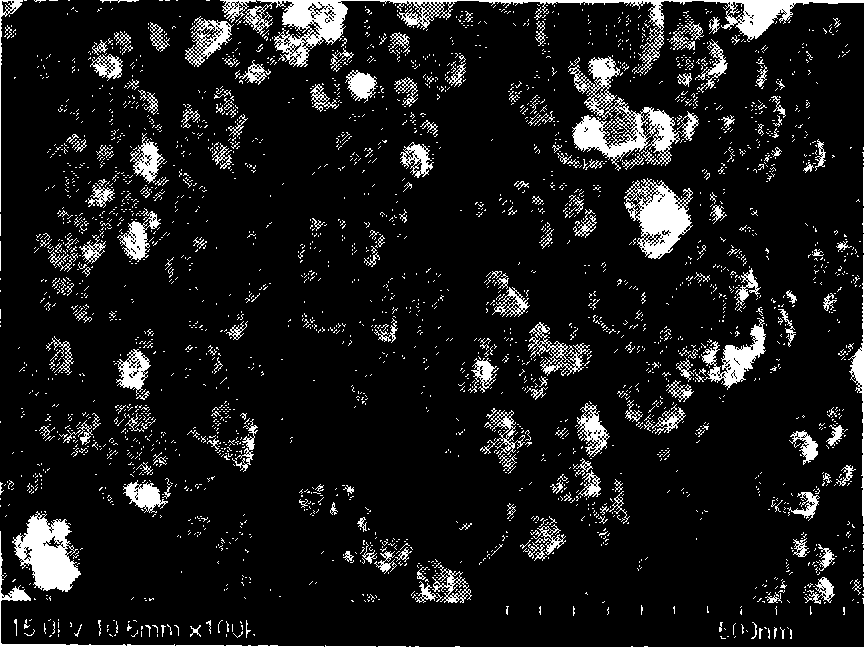

Image

Examples

Embodiment 1

[0043] Using sodium-reduced tantalum powder as raw material, after plasma spheroidization treatment, the process parameters of spheroidization treatment are shown in Table 1, and then pass through a 200-mesh sieve, and the 200-mesh powder is sorted and classified. The process parameters are: powder feeding The rate is 2kg / hour, the classified gas flow rate is 300 standard liters / minute, the average particle size of the powder is 3μm, and the standard deviation is 1.2μm. The selected parameters after plasma spheroidization are as follows:

[0044] Table 1 Selected plasma spheroidization process parameters

[0045]

[0046] The particle size and impurity content of the powder treated with the induction plasma capacitor grade tantalum powder are compared with the national standard FTA120 high specific volume tantalum powder, as shown in Table 2:

[0047] Table 2 Test results of particle size and impurity content

[0048]

[0049] Note: "Spin" in the table means cyclone se...

Embodiment 2

[0051] Using sodium-reduced tantalum powder as raw material, after plasma spheroidization treatment, the process parameters of spheroidization treatment are shown in Table 3, and then pass through a 200-mesh sieve, and the 200-mesh powder is sorted and classified. The process parameters are: powder feeding The rate is 3kg / hour, the classified gas flow rate is 400 standard liters / minute, the average particle size of the powder is 4μm, and the standard deviation is 1μm. The process parameters of spheroidization treatment are as follows:

[0052] Table 3 Selection of plasma spheroidization process parameters

[0053]

[0054] The particle size and impurity content of the powder treated with the induction plasma capacitor grade tantalum powder are compared with those of the national standard FTA120 high specific volume tantalum powder, as shown in Table 4:

[0055] Table 4 Test results of particle size and impurity content

[0056]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com