Method for preparation of functional low polyxylose alcohol

A technology of xylo-oligosaccharides and xylo-oligosaccharides, applied in the field of biochemistry, can solve problems such as short (6 months, low sweetness, incompatibility, etc.), and achieve improved physical and chemical properties, soft taste and pure flavor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

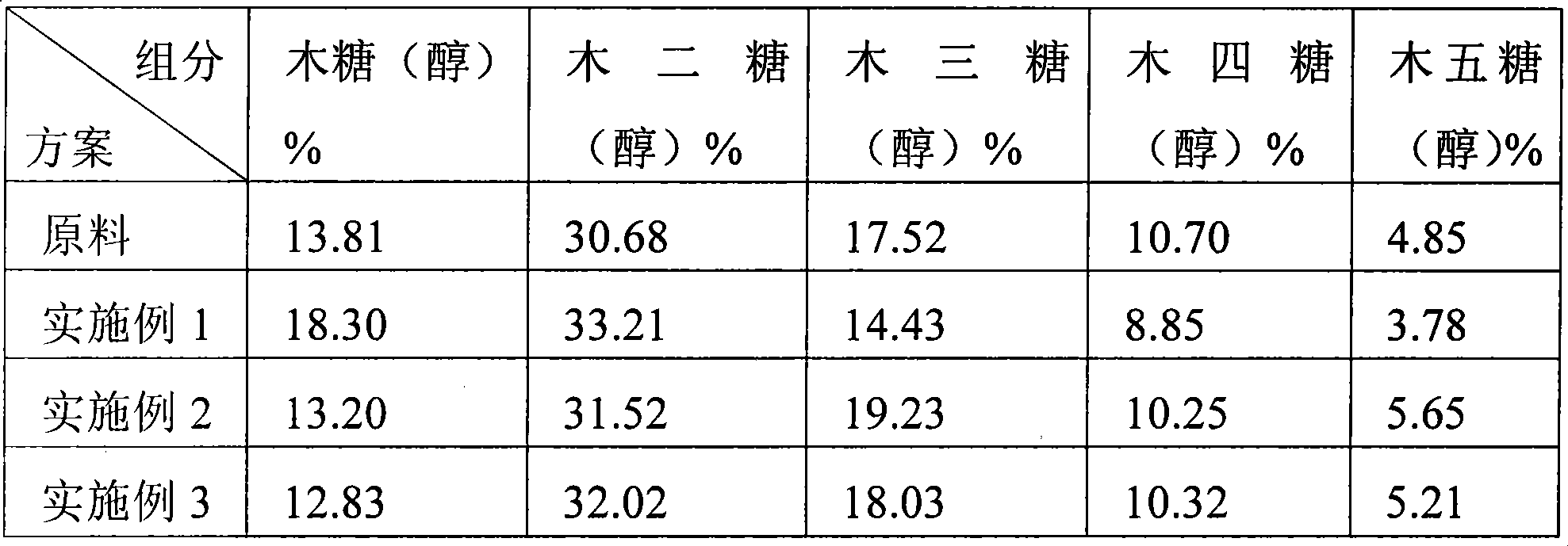

Embodiment 1

[0018] Get 0.90kg of xylo-oligosaccharide syrup (xylo-oligosaccharide accounts for 70% of the total sugar ratio) of 70.8% refraction that has been sold publicly by Shandong Longli Biotechnology Co., Ltd., add pure water to adjust the solid content to 16% 1. Add 57g of Raney nickel catalyst, stir evenly, then adjust the pH value to 7.2 with caustic soda NaOH, open the reaction kettle, pour the adjusted xylooligosaccharide solution into the kettle, close the lid of the kettle, and replace the inside of the kettle with nitrogen gas Air and pressure test, then add hydrogen, start heating, adjust the pressure to 12MPa, pay close attention to the pressure change during the whole hydrogenation reaction process, and replenish the pressure in time according to the progress of the reaction. When the temperature rises to 70°C, the reaction starts. When the temperature rises to 125°C, stop heating, start heat preservation and pressure holding, and start timing. The DE value is detected at ...

Embodiment 2

[0020]Get the xylo-oligosaccharide syrup (xylo-oligosaccharide accounts for 70% of total sugar ratio) 3.0kg that the publicly sold refraction that Shandong Longli Biotechnology Co., Ltd. produces is 70.5%, add pure water and solid content water is adjusted to 53 %, add 253g of Raney nickel catalyst, stir evenly, then adjust the pH value to 8.0 with caustic soda NaOH, open the reaction kettle, pour the adjusted xylooligosaccharide solution into the kettle, close the lid of the kettle, and replace the kettle with nitrogen gas first Inner air and pressure test, then add hydrogen, start heating, adjust the pressure to 11MPa, pay close attention to the change of pressure during the whole hydrogenation reaction process, and replenish the pressure in time according to the progress of the reaction, when the temperature rises to 70°C, the reaction starts , when the temperature rises to 110°C, stop heating, start heat preservation and pressure holding, and start timing. The DE value is d...

Embodiment 3

[0022] Get 2.5kg of xylo-oligosaccharide syrup (xylo-oligosaccharide accounts for 70% of the total sugar ratio) of 70.5% refraction that has been sold publicly by Shandong Longli Biotechnology Co., Ltd., add pure water to adjust the solids content to 45% %, add 123.5g of Raney nickel catalyst, stir evenly, then adjust the pH value to 7.9 with caustic soda NaOH, open the reaction kettle, pour the adjusted xylooligosaccharide solution into the kettle, close the lid of the kettle, and replace it with nitrogen gas first The air in the kettle is tested for pressure, then hydrogen is introduced, and heating is started, and the pressure is adjusted to 9MPa. During the whole hydrogenation reaction process, pay close attention to the pressure change. At the beginning, stop heating when the temperature rises to 100°C, start heat preservation and pressure holding, and start timing. The DE value is detected at 20 minutes to 0.36%; the DE value is detected to be 0.12% at 30 minutes; the DE ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com