Processing method of thin-wall copper tube end cold forming seal

A processing method and technology of copper tubes, which are applied in the field of processing metal pipe parts for pipe end sealing, can solve problems such as harmful to human health, increased electroplating production, and large waste of materials, and achieve low cost, reduced production cycle and cost, and materials. The effect of high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

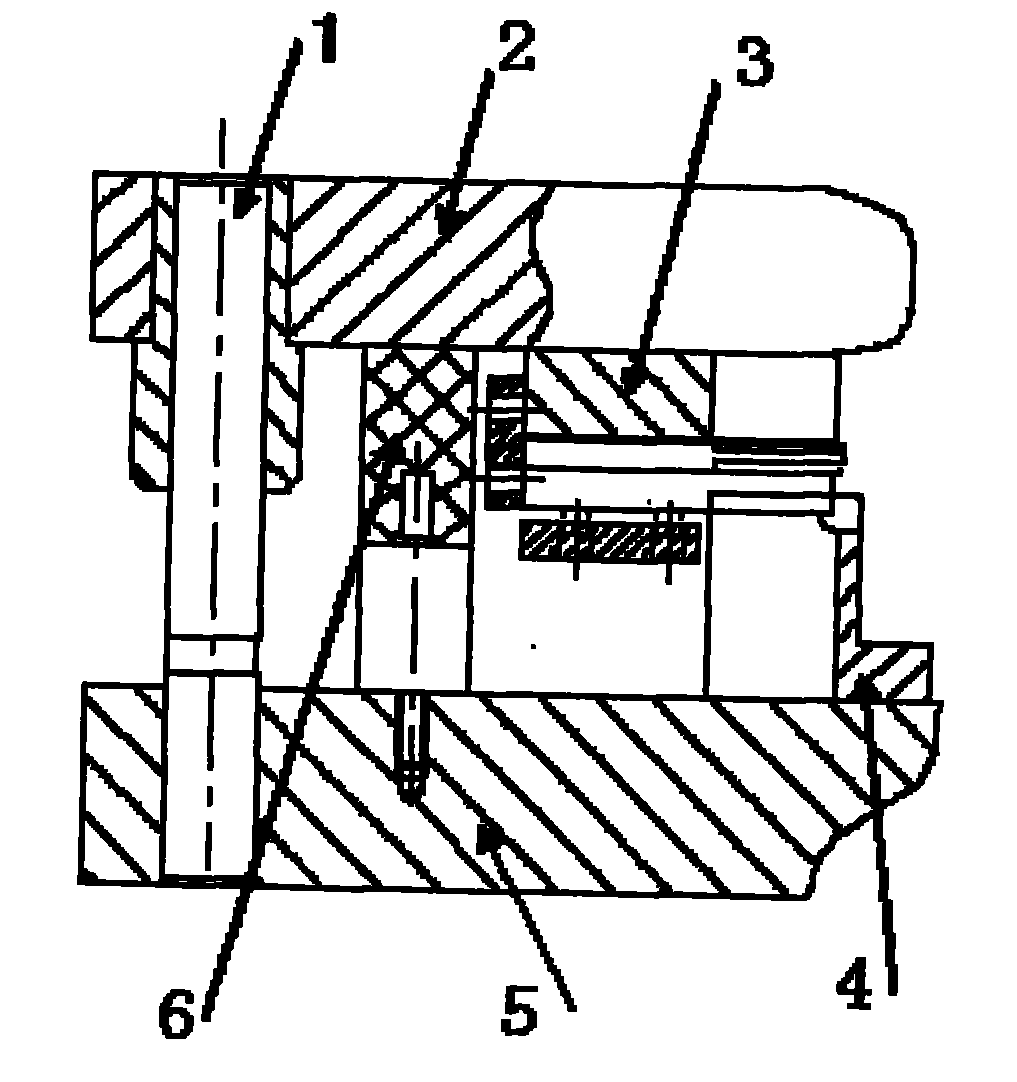

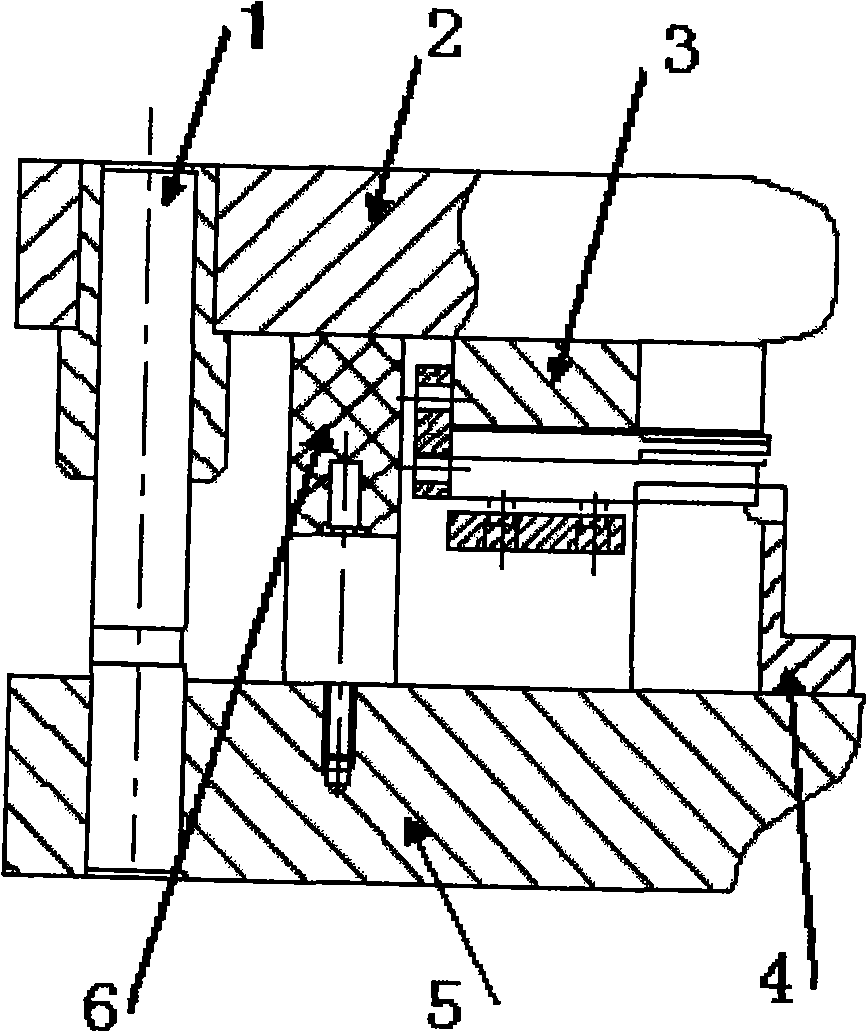

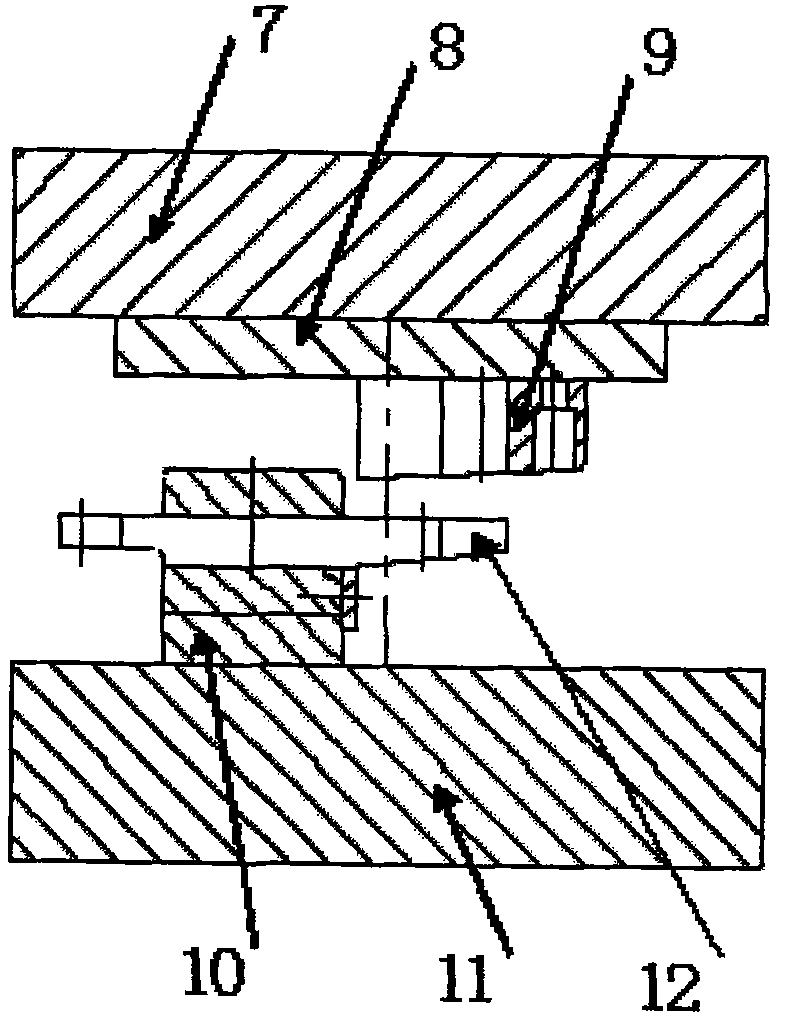

[0017] The specific embodiment of the present invention can refer to accompanying drawing 3. The entire product forming process is to first cut the tube blank into a certain length of metal hollow pipe fittings, and under the action of the manipulator, send the tube blank to the punch 12 in the notch die in the accompanying drawings 1 and 2 for positioning, and the die 9 goes down After the end face of the pipe fitting is cut into the size and shape required in the process flow table, it is sent to the punch 3 at the die opening position of the main mold of the flanging die, and then the pipe fitting cut into a certain shape is passed down through the die 4 along the two sides. The side wall is straightened, the flanging is formed, and then the formed part is withdrawn from the main mold under the action of the thimble of the ejection mechanism, and the robot puts it on another workbench, and the hollow tube softened by the recrystallization annealing process On another two-st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com