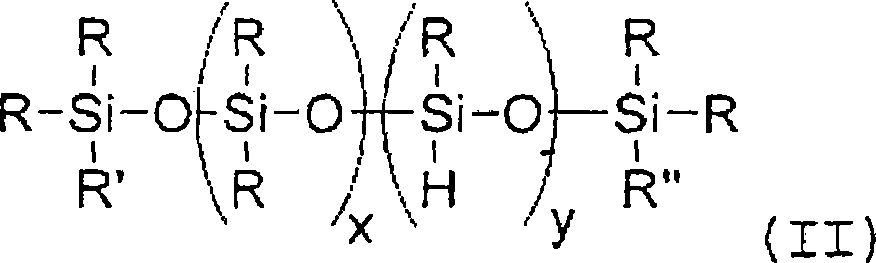

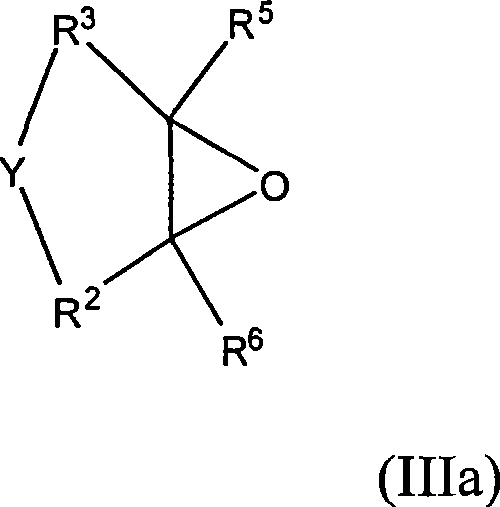

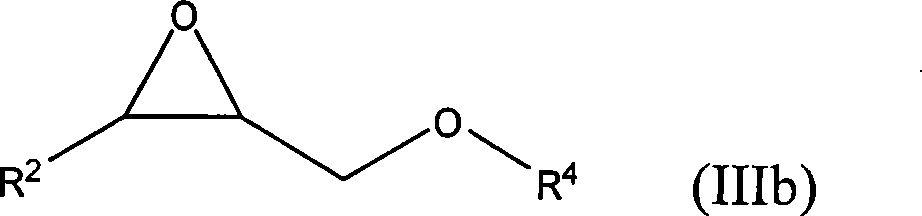

Method for producing polyether alcohols with dmc catalysts using compounds containing sih combinations as additives

A technology of DMC catalyst and polyether alcohol, which is applied in the direction of chemical instruments and methods, chemical/physical processes, transportation and packaging, etc., and can solve problems such as inability to approach polydispersity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1a

[0103] At first under nitrogen, add 215.7g polypropylene glycol (weight average molecular weight M in the autoclave of 3 liters) w =2000g / mol), 0.03g of hexacyanocobaltate (III) zinc DMC catalyst and 5.9g of heptamethylhydrotrisiloxane (Rhodia) (CAS[1873-88-7] with a SiH content of 4.5eq / kg ), and heated to 130°C with stirring. The reactor was evacuated to an internal pressure of 30 mbar in order to remove by distillation any volatile constituents present. To activate the DMC catalyst, a 40.0 g portion of propylene oxide was added. After the reaction had started and the internal pressure had dropped, a further 944 g of propylene oxide were metered in continuously within 60 minutes with cooling to 130° C. and a maximum reactor internal pressure of 1.5 bar. The reaction was continued at 130° C. for 30 minutes, followed by a degassing step. This removes volatile components such as residual propylene oxide by distillation at 130°C under reduced pressure. The resulting polyethe...

Embodiment 1b

[0107] In other comparative experiments carried out similarly to Example 1a, no additives were added to the polypropylene glycol / DMC catalyst mixture at the start of the alkoxylation according to the current state of the art.

[0108] The resulting long-chain, low-viscosity polypropylene glycol has an OH value of 9.8 mg KOH / g, a viscosity (at 25°C) of 7100 mPas, and according to GPC, its polydispersity M w / M n 1.4 (relative to polypropylene glycol standard).

[0109]

[0110] Preparation of mixed ethylene oxide / propylene oxide-based polyethers with addition of additives by the process of the invention

Embodiment 2a

[0112] First add 180.0g polypropylene glycol monoallyl ether (weight average molecular weight M to 3 liters of autoclave under nitrogen) w =400g / mol), 0.08g of zinc hexacyanocobaltate DMC catalyst and 5.25g of heptamethylhydrotrisiloxane (CAS[1873-88-7]), and heated to 130°C with stirring. The reactor was evacuated to an internal pressure of 30 mbar in order to remove by distillation any volatile constituents present. To activate the DMC catalyst, a 36.0 g portion of propylene oxide was added. After the reaction had started and the internal pressure had dropped, a mixture of 396 g of ethylene oxide and 1269 g of propylene oxide was metered in continuously within 90 minutes while cooling to 130° C. and a maximum reactor internal pressure of 1.5 bar. The reaction was continued at 130°C for 30 minutes, followed by a degassing step. This removes volatile components such as residual propylene oxide by distillation at 130°C under reduced pressure. The resulting polyether is coole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com