Method for purifying and liquefying coalbed gas

A coalbed methane and liquid technology, which is applied in the field of coalbed methane purification and liquefaction, can solve the problems of unsafe deoxidation after pressurization, unable to meet production needs, and small production capacity of daily processing raw coal seams, and achieves expansion of transportation and utilization radius, compression safety, etc. Guaranteed and improving the effect of gas extraction and drainage utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

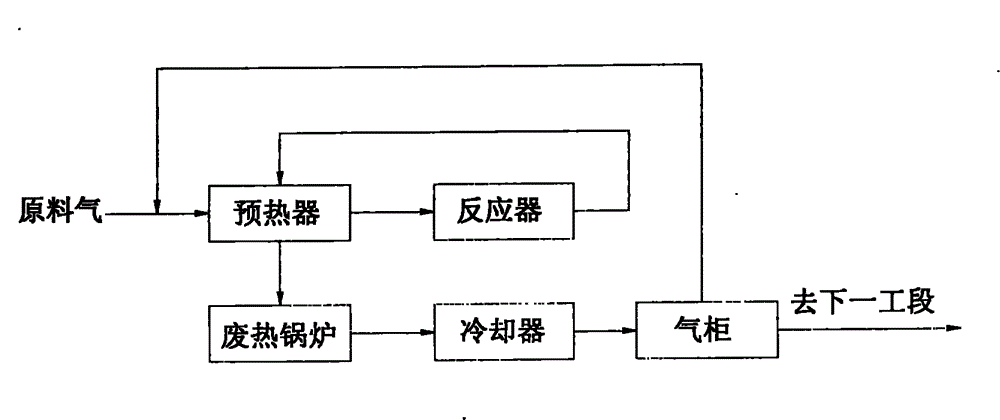

[0009] exist figure 1 Among them, a process in the purification and liquefaction method of coalbed methane, deoxidation: the sulfur-resistant catalytic deoxidation process is that the raw material coalbed methane is mixed with part of the deoxygenated circulating gas in the gas tank at 70Kpa, and enters the reactor after being preheated by the preheater. In the temperature range of 500°C-700°C, methane and oxygen react in the catalyst bed to form CO 2 and H 2 O: After the high-temperature deoxygenation enters the preheater and the reaction raw material gas is transferred by heat, the waste heat boiler generates steam to recover heat, and enters the gas cabinet after cooling;

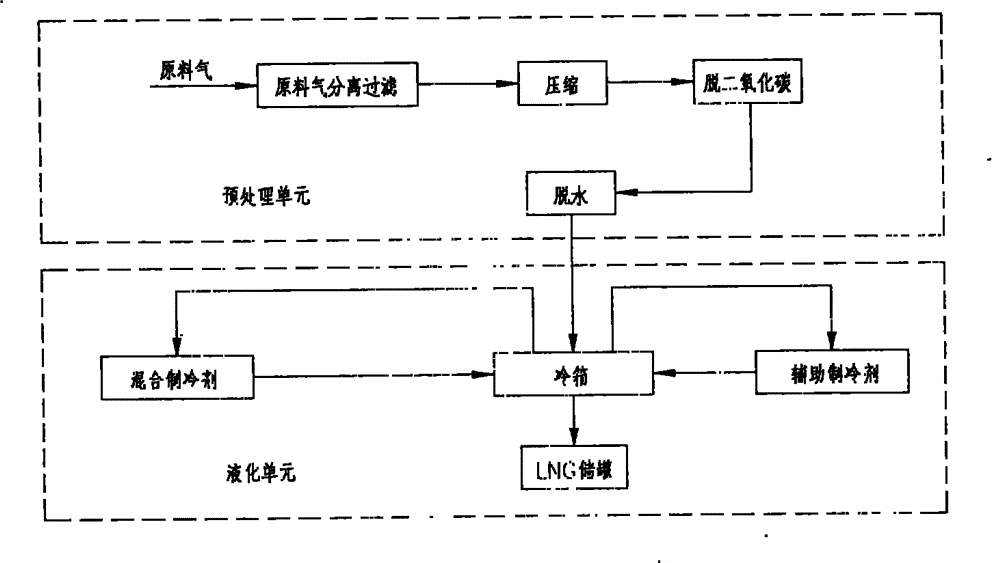

[0010] exist figure 2 Among them, the coalbed methane purification and liquefaction method is realized through the following processes: raw material coalbed methane - deoxygenation - pressurization - decarburization - dehydration - denitrogenation - storage and transportation: from figure 1 Pressuriz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com