Method for extracting lithium by drying lepidolite with waste heat

A technology for extracting lithium from lepidolite, applied in the field of lithium extraction from lepidolite, can solve problems such as low recovery rate, easy dusting, environmental pollution, etc., and achieve the effects of improving extraction utilization, reducing energy consumption, and shortening reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

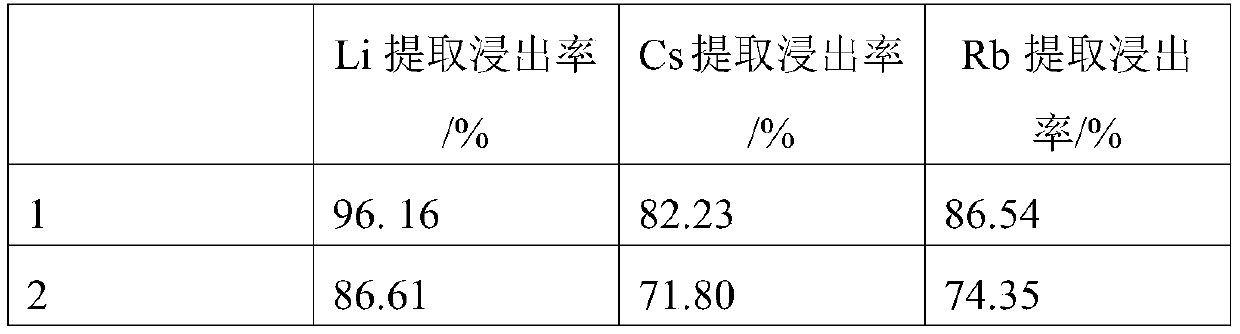

Embodiment 1

[0026] The invention discloses a method for extracting lithium salt by drying lepidolite with waste heat. It uses lepidolite as a raw material and uses a rotary kiln for roasting. The raw material used in this example is lepidolite produced by a certain tantalum-niobium-lithium mine in Yichun. Raw material, its main chemical composition is as follows table (wt%) surplus is fluorine, table 1:

[0027] Li 2 o

K 2 o

Na 2 o

AL 2 o 3

SiO 2

Fe 2 o 3

Rb 2 o

Cs 2 o

3.24 12.76 0.61 24.01 52.78 0.51 1.66 0.40

[0028] The invention discloses a method for extracting lithium salt by drying lepidolite with waste heat, using lepidolite as a raw material, and adopting a rotary kiln roasting method; it includes the following method steps,

[0029] 1) The raw material is pulverized, and the lithium ore raw material is placed in a crushing device for pulverization to be lepidolite raw material powder;

[0030] 2) waste ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com