Ant-apex contact heterojunction solar battery and preparation method thereof

A solar cell and heterojunction technology, applied in circuits, photovoltaic power generation, electrical components, etc., to achieve the effects of easy implementation, high photoelectric conversion efficiency, and avoiding contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

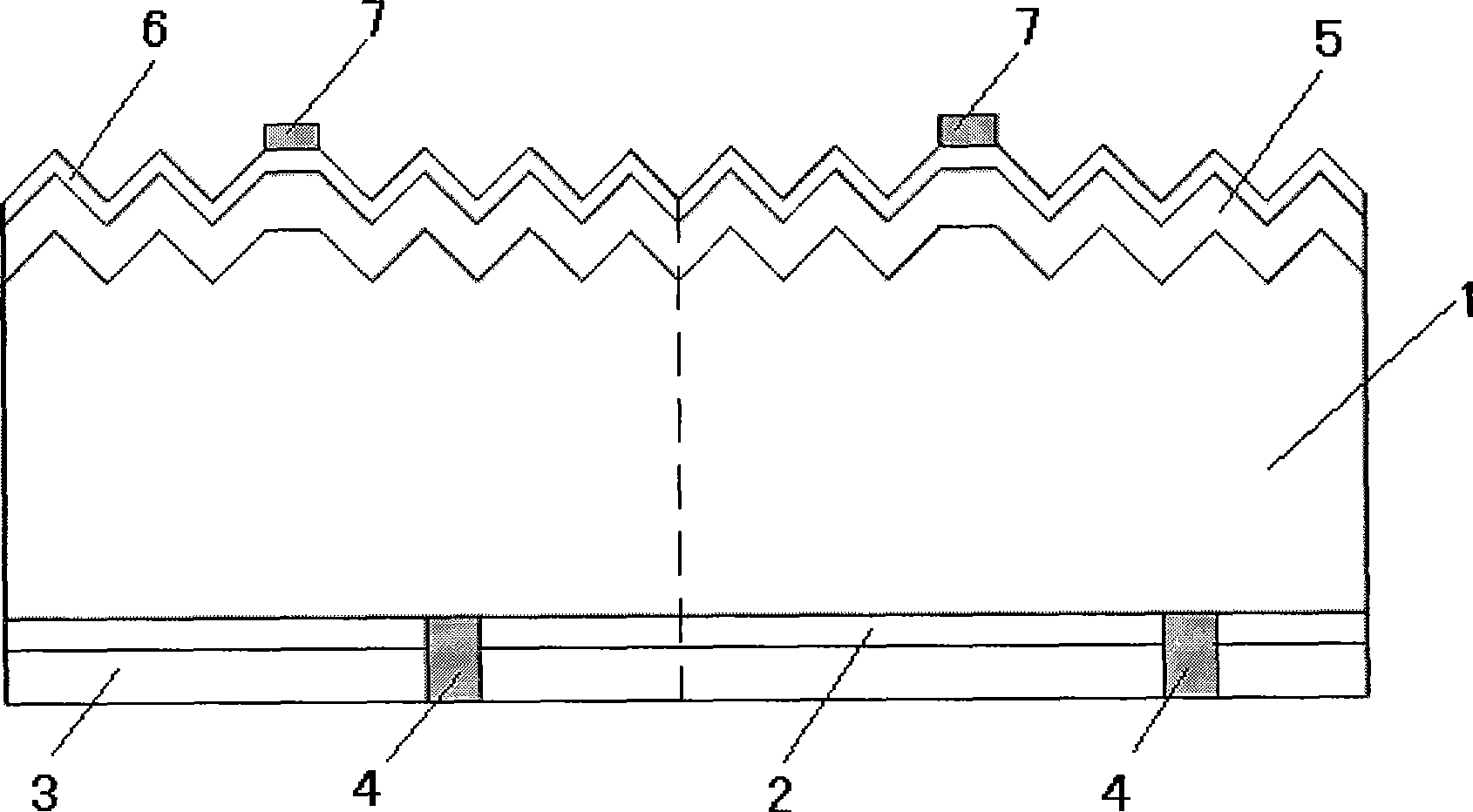

[0015] Such as figure 1 Shown is a schematic diagram of the structure of two adjacent units in the back point contact heterojunction solar cell of the present invention, and a solar cell is composed of many such units. Each unit is arranged on a silicon substrate 1, and then a complete solar panel is obtained by connecting multiple units.

[0016] The silicon substrate 1 of the present invention is a P-type or N-type single crystal silicon wafer with a thickness of 200-500 μm and a resistivity of 0.3-500 Ωcm, and the silicon substrate 1 is used as a base area of a solar cell. Prepare a passivation layer 2 made of one of heavily doped amorphous silicon or microcrystalline silicon or silicon dioxide with a thickness of 50-80 nm on the back surface of the silicon substrate 1 to reduce the flow of carriers on the silicon substrate 1 Composite of back ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com