Anti-bacterial agent and production method of anti-biotic chip for sanitary towel

An antibacterial agent and silver-based antibacterial agent technology, applied in the field of sanitation and disinfection products, can solve the problems of wide applicability, allergic reaction, and easy shedding that affect safety, and achieve the advantages of avoiding women's menstrual infection, long-lasting antibacterial time, and strong bactericidal activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Dissolve 4 parts of silver ion antibacterial emulsion, 5 parts of screen printing glue and 0.2 part of pink dye into 91 parts of water, stir for about 20 minutes to fully dissolve, and configure an adhesive antibacterial agent.

[0016] The silver ion antibacterial emulsion is a water-soluble antibacterial emulsion configured by silver-based antibacterial agents and OP series surfactants.

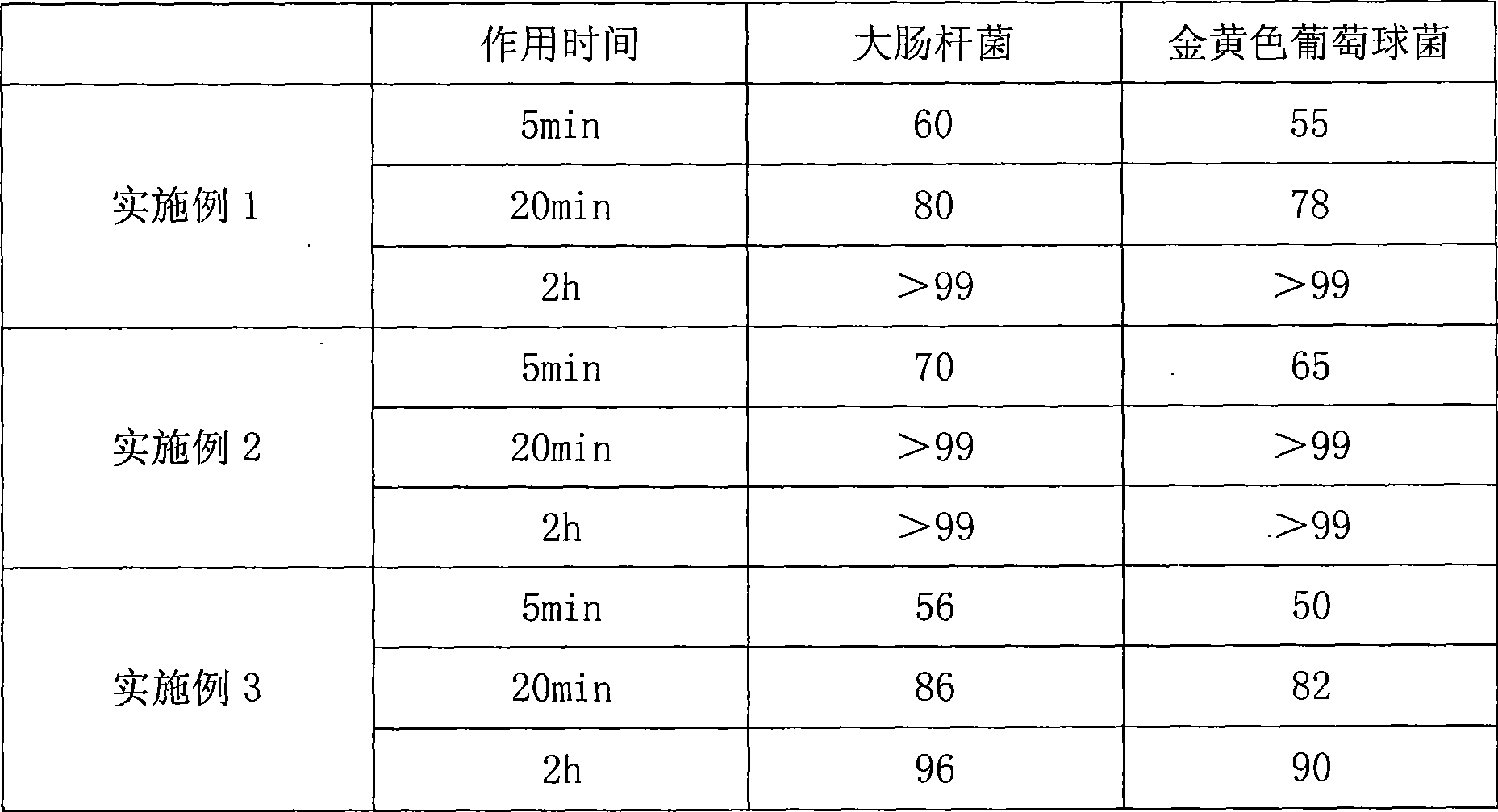

[0017] In the last step of gluing in the production of non-woven fabrics, the above-mentioned antibacterial agents are adhered to the non-woven fabrics, dried to produce antibacterial non-woven fabrics, and then the non-woven fabrics are made into sizes according to the specifications of sanitary napkins. chip. The results of the test (antibacterial effect is tested by GB15979-2002 hygiene standard for disposable hygiene products) antibacterial nonwoven fabric are shown in Table 1.

Embodiment 2

[0019] Dissolve 5 parts of silver ion antibacterial emulsion, 5 parts of screen printing glue and 0.2 part of pink dye into 90 parts of water, stir for about 20 minutes to fully dissolve, and configure an adhesive antibacterial agent.

[0020] The silver ion antibacterial emulsion is a water-soluble antibacterial emulsion formulated with silver-based antibacterial agents and Pingjia series surfactants.

[0021] The antimicrobial agent is used in the last step of the gluing process in the production of nonwovens to produce antibacterial nonwovens, which are then made into size-fitting chips according to the specifications of sanitary napkins. The results of the test (antibacterial effect is tested by GB15979-2002 hygiene standard for disposable hygiene products) antibacterial nonwoven fabric are shown in Table 1.

Embodiment 3

[0023] Dissolve 5 parts of silver ion antibacterial emulsion, 3 parts of screen printing glue and 0.2 part of pink dye into 92 parts of water, stir for about 20 minutes to fully dissolve, and configure an adhesive antibacterial agent.

[0024] The silver ion antibacterial emulsion is a water-soluble antibacterial emulsion prepared by silver-based antibacterial agent and Tween-30 surfactant.

[0025] The antimicrobial agent is used in the last step of the gluing process in the production of nonwovens to produce antibacterial nonwovens, which are then made into size-fitting chips according to the specifications of sanitary napkins. The results of the test (antibacterial effect is tested by GB15979-2002 hygiene standard for disposable hygiene products) antibacterial nonwoven fabric are shown in Table 1.

[0026]

[0027] Table 1 Antibacterial sanitary napkin antibacterial performance test results

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com