ITO film laser engraving device and method

A laser etching, thin film technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of poor linearity of conductive film layers, increase equipment cost, reduce service life, etc., to reduce the impact of human operation, Ease of circuit design, effect of protecting substrate materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

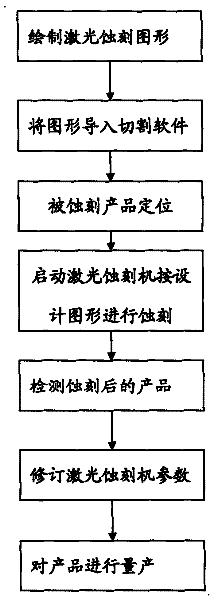

Method used

Image

Examples

Embodiment Construction

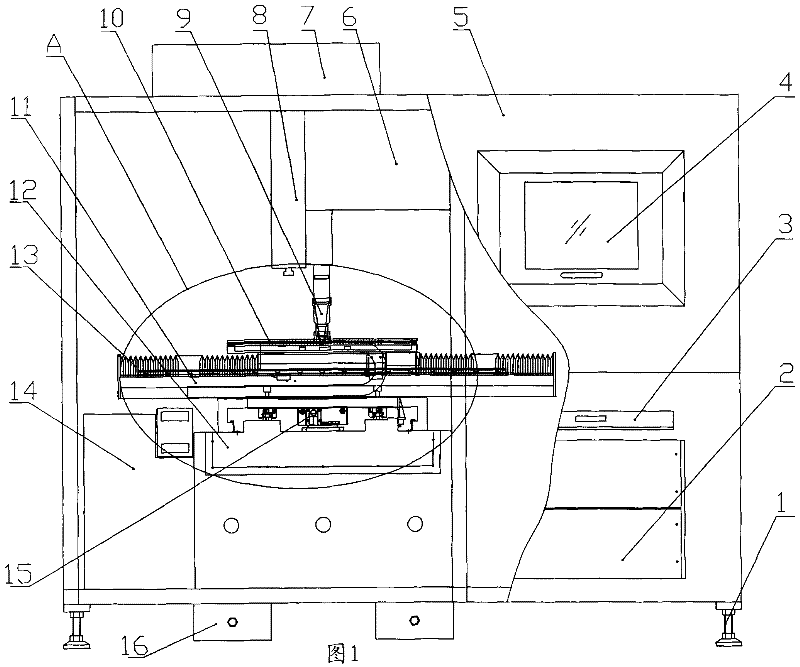

[0031] Such as Figure 1 to Figure 3 As shown, the laser etching equipment of the present invention includes a foot support adjustment bolt 1, an industrial computer 2, a keyboard and mouse drawer box 3, a display system 4, a frame 5, a laser generator 6, a fan filter unit (FFU) 7, and a Axis motion system 8, cutting head 9, suction disc 10, X-axis motion system 11, Y-axis motion system 12, dust cover 13, electrical control cabinet 14, linear motor 15, shockproof pad iron 16, sliding wheel 17, red light Inductance device 18, automatic door protection device 19, cylinder shaft 20, casters 21;

[0032] The industrial computer 2, the laser generator 6, the Z-axis motion system 8, the display system 4, the fan filter unit (FFU) 7, and the automatic door protection device 19 are all installed on the frame 5, and the cutting head 9 is installed on the Z axis. On the axis motion system 8, it is located above the adsorption disc 10, and the adsorption disc 10 is fixedly installed on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com