Method for extracting beta-amylase from potato cell tissue

A technology of cell tissue and amylase, applied in the direction of hydrolytic enzymes, etc., to achieve the effects of good color, low cost, significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: A method for extracting β-amylase from potato cell tissue

[0033] The detailed steps of this method are as follows:

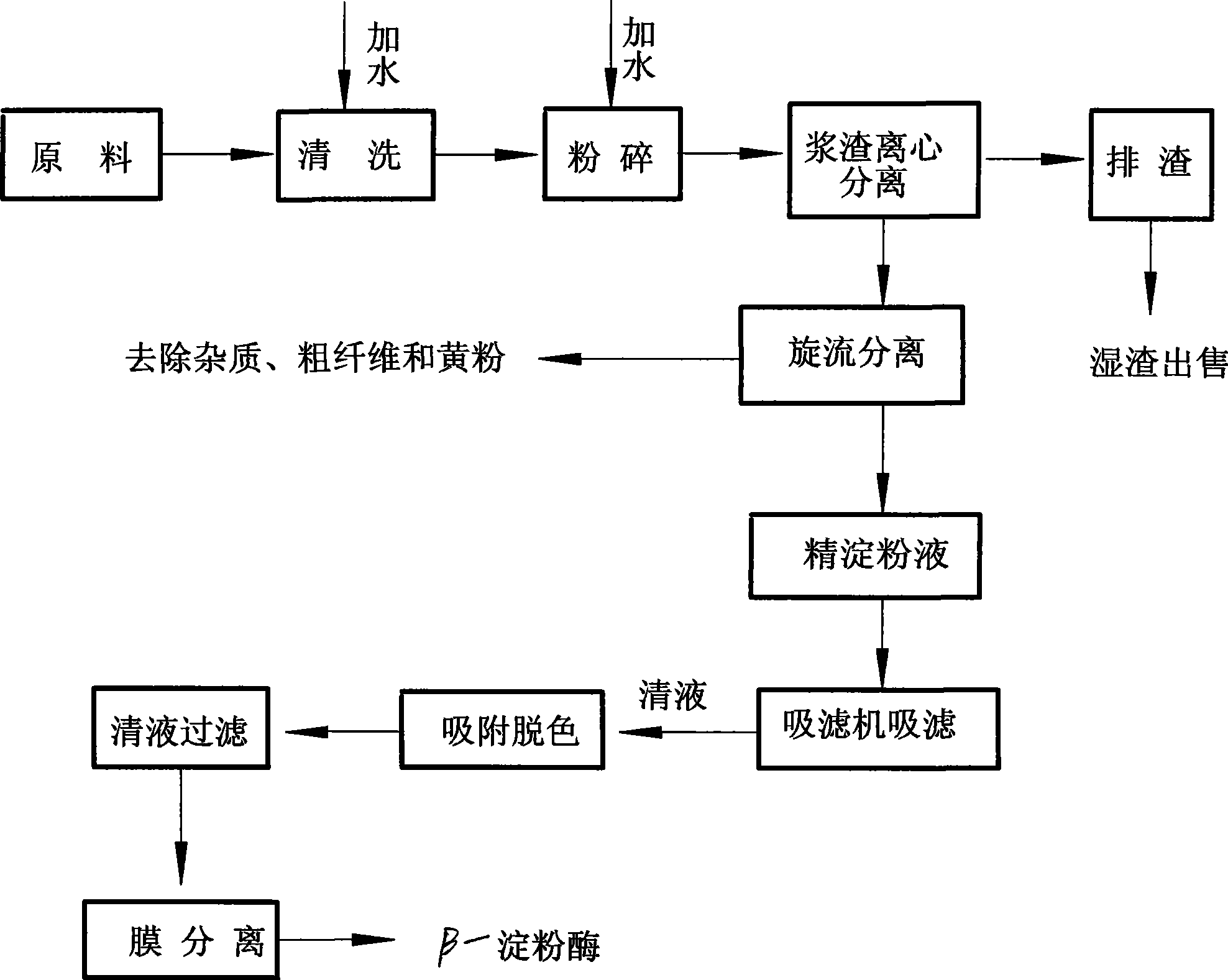

[0034] See attached figure 1 , the prepared sweet potatoes are cleaned in the cylinder machine, and after cleaning, they are crushed by adding water to the file grinder, and the crushed slurry residue is centrifugally separated, and the wet residue discharged after separation is sold, and the slurry is separated by cyclone, separated Impurities, crude fibers and yellow powder are removed, and the refined starch liquid obtained after cyclone separation is sucked and filtered by a vacuum suction filter. The wet starch is bonded to the outer layer of the 120-7 filter cloth, and the clear liquid flows out. The clear liquid is further processed to extract β - Amylase, the following detailed steps are:

[0035] a. The clear liquid obtained after the suction filtration is introduced into the decolorizer, and an activated carbon decolorizer accoun...

Embodiment 2

[0039] Embodiment two: a kind of method for extracting β-amylase from tuber cell tissue, basically the same as embodiment one, the difference is:

[0040] The decolorizer that adopts in the step a is gac, and its add-on accounts for 2.5% of clear liquid amount;

[0041] In step b, three filter adsorptions of 300# diatomite, a mixture of 300# and 600# diatomite, and 600# diatomite uniformly pre-coated on the 120-10 filter cloth,

[0042] The thickness of the polyethersulfone membrane in step c is 20 microns.

Embodiment 3

[0043] Embodiment three: a kind of method for extracting β-amylase from tuber cell tissue, basically the same as embodiment one, the difference is:

[0044] The decolorizing agent adopted in the step a is gac, and its addition accounts for 3% of clear liquid amount;

[0045] In step b, pass through the 300# diatomite evenly pre-coated on the 120-10 filter cloth, the mixture of 300# and 600# diatomite on the 120-7 filter cloth, and the 600# diatomite on the 120-10 filter cloth Three filter adsorption;

[0046] The thickness of the polyethersulfone membrane in step c is 18 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com