High-moisture tissue protein production device

A technology of tissue protein and production equipment, applied in the field of soybean protein food processing equipment, can solve the problems of short screw, difficult to popularize, and poor taste of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

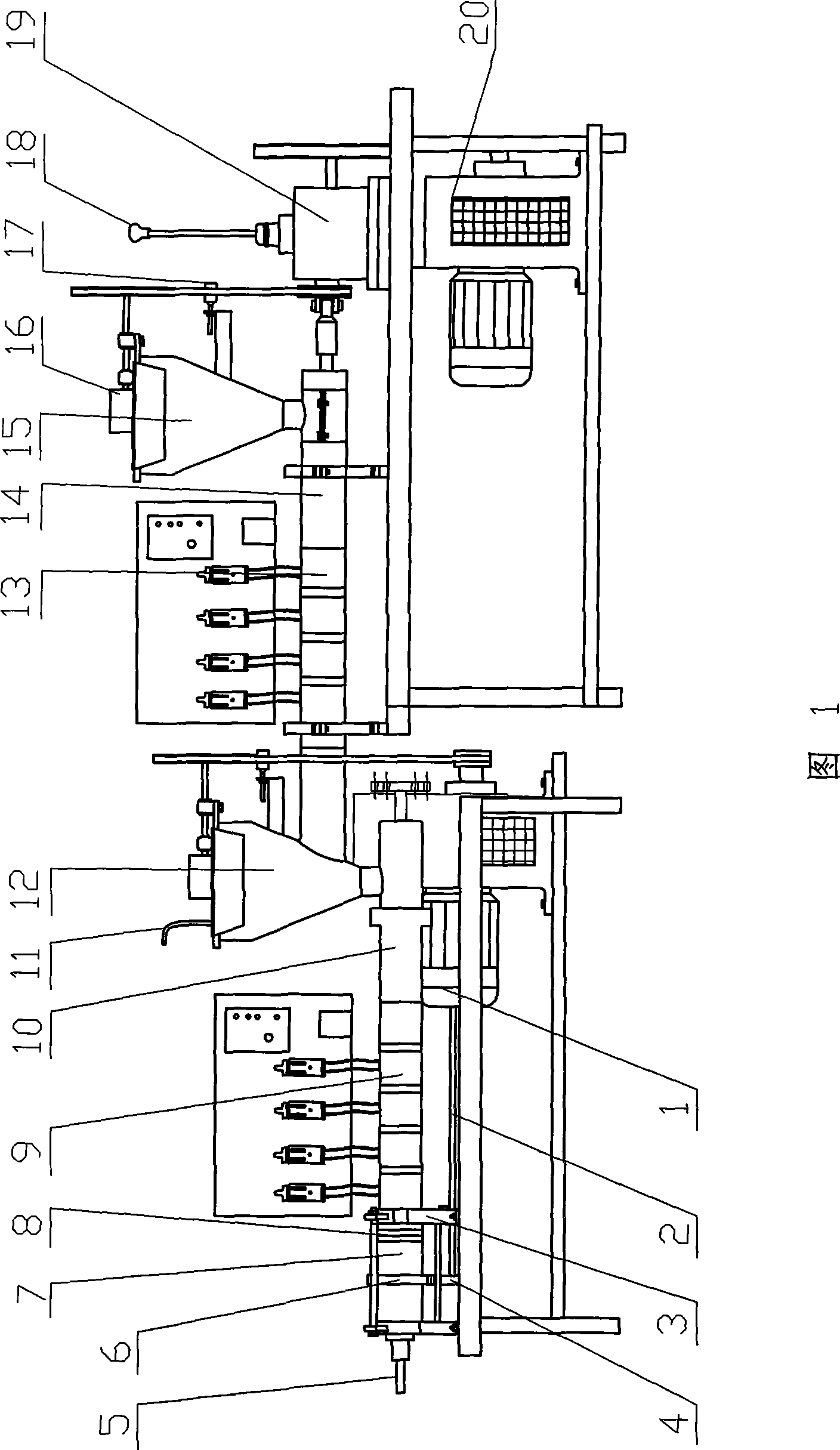

[0011] In the embodiment shown in Figure 1, the device includes two parts, the main machine and the auxiliary machine. The main structures of the main machine and the auxiliary machine are generally the same, including a frame, a transmission mechanism and a feeding system. The auxiliary motor 20 on the auxiliary machine is installed on the bottom of the frame body, the auxiliary motor 20 is connected with the gearbox 19, and the gearbox 19 regulates the output speed through the gear handle 18. The power output end of the gearbox 19 is respectively connected with the auxiliary machine screw and the agitator 16, the auxiliary machine screw is placed in the auxiliary material cylinder 14, and the auxiliary material cylinder 14 is fixed on the support. The auxiliary hopper 15 is located at the right end of the auxiliary material cylinder 14, and the agitator 16 is arranged on the top of the auxiliary hopper. A plurality of auxiliary heating jackets 13 are designed in the middle o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com