Combination type drying machines controller

A dryer and combined technology, applied in the direction of machine/engine, liquid variable capacity machinery, mechanical equipment, etc., can solve the problems of large maintenance volume of single-chip controller, fragile processor CPU, weak anti-drying ability, etc. Achieve the effect of obvious energy saving, perfect function and simple wiring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

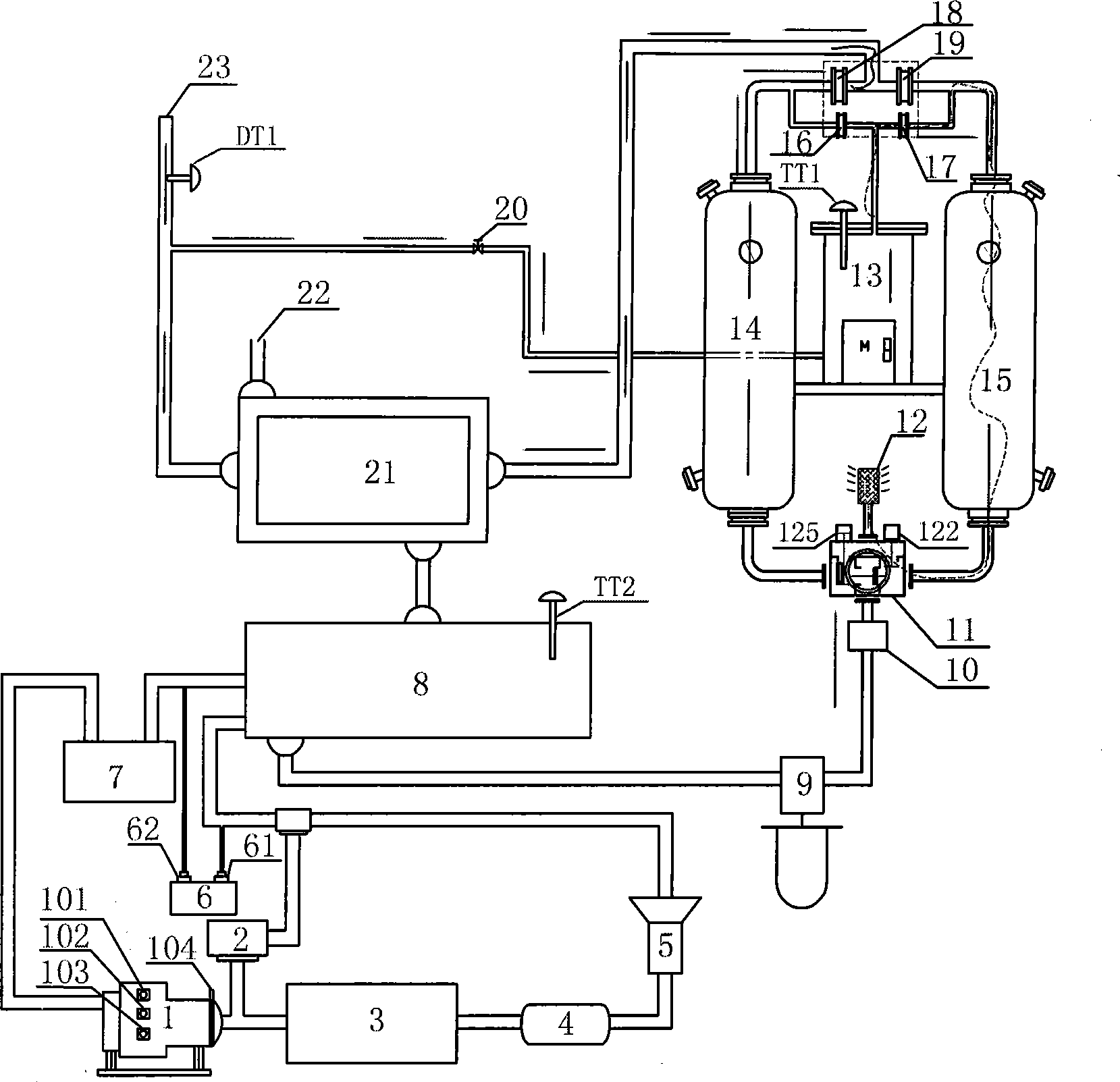

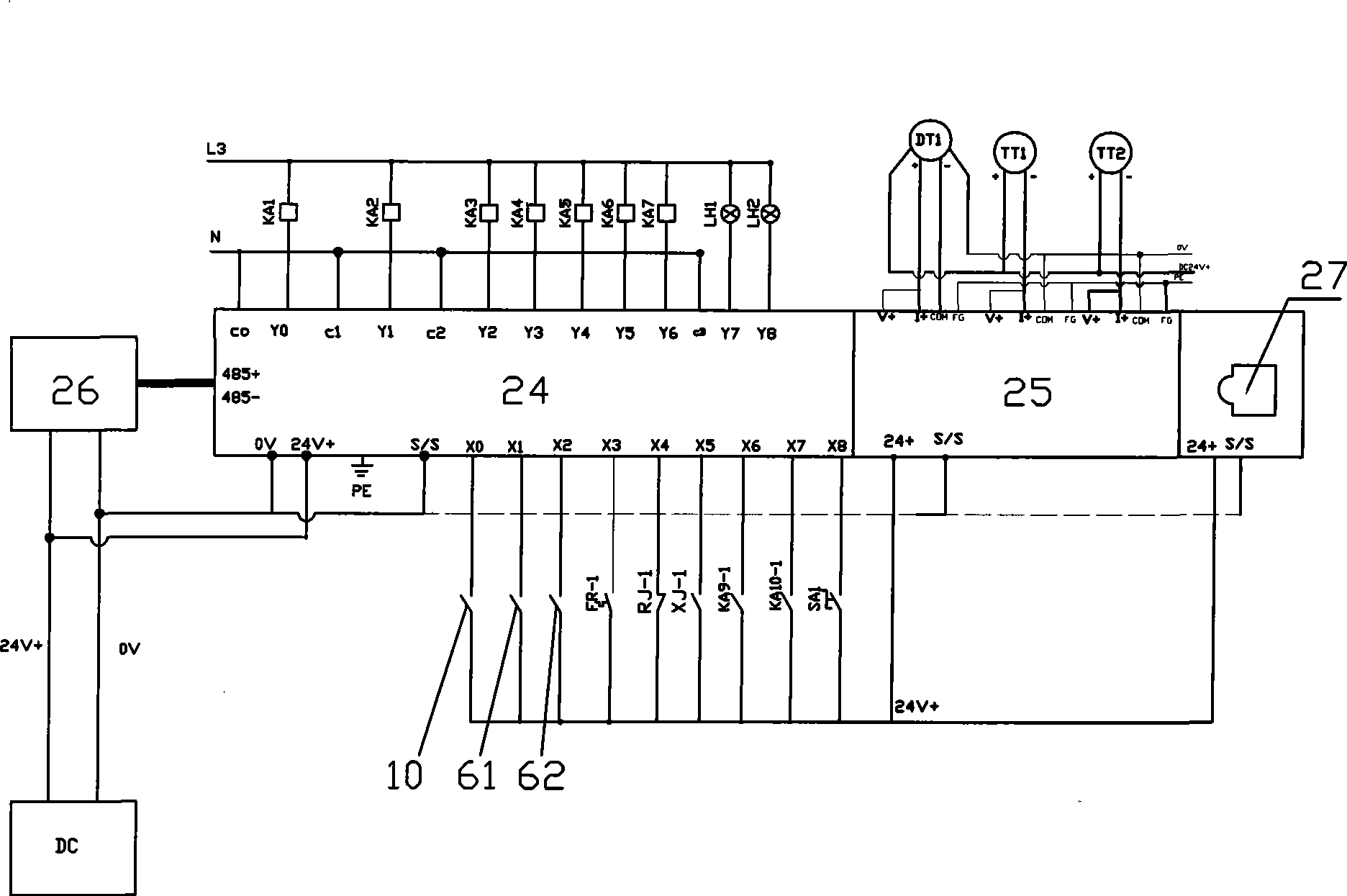

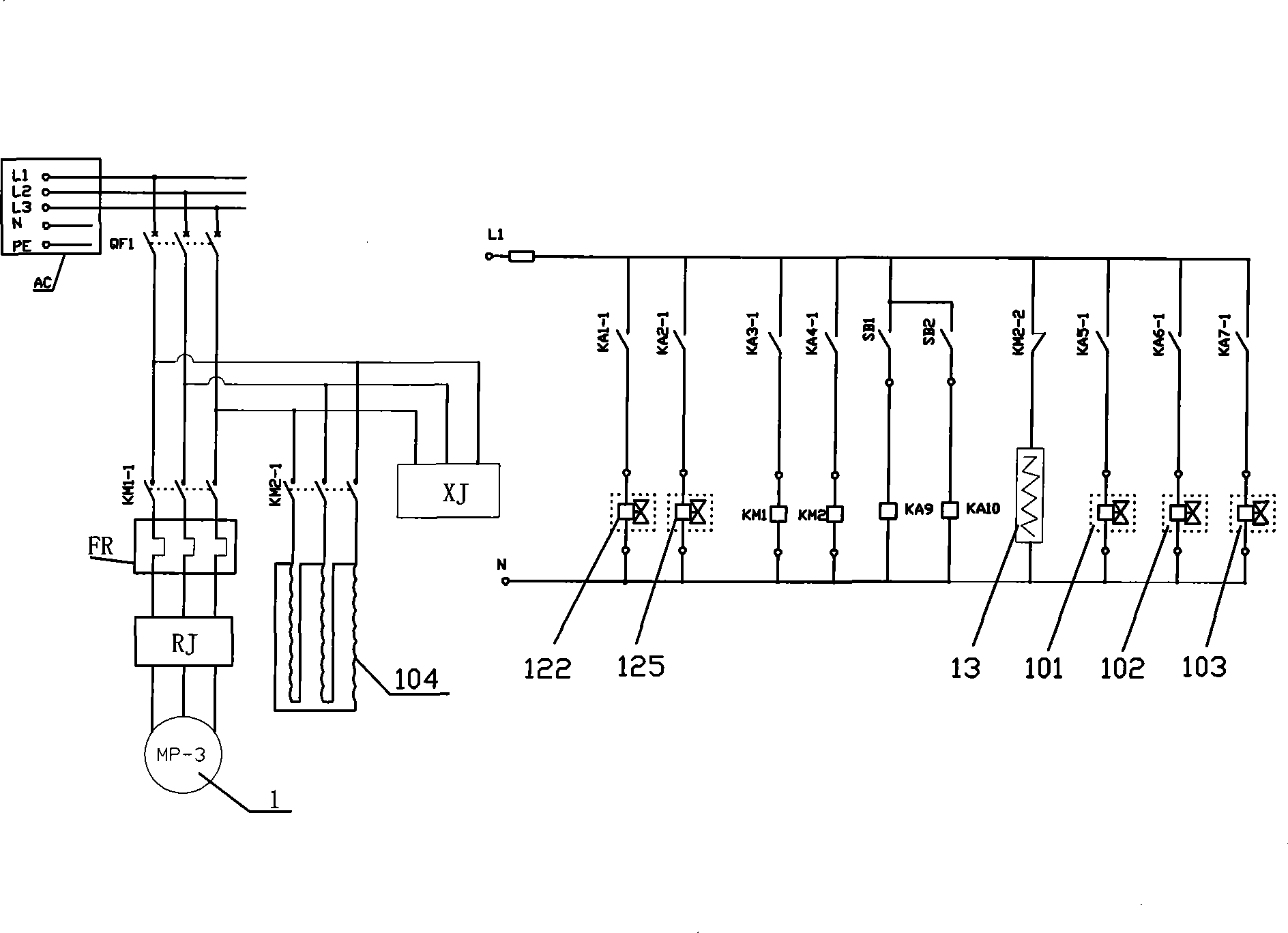

[0019] Such as figure 1 , figure 2 and image 3 As shown, the combined dryer controller includes a programmable controller 24. The programmable controller 24 is connected with an analog signal conversion module 25 and a small man-machine interface 26. The analog signal input port of the analog signal conversion module 25 is connected with the finished product respectively. The gas dew point temperature transmitter DT1, the heater temperature transmitter TT1, and the air dryer dew point temperature transmitter TT2 are connected; the first to ninth input ports of the programmable controller 24 are respectively connected to the pressure switch 10 and the high and low pressure switch 6 The low voltage contact 61 of the high and low voltage switch 6, the high voltage contact 62 of the high and low voltage switch 6, the normally open contact FR-1 of the overload...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com