Plasma biology deodorization technique and system of vent gas from steel-drum spray-painting production line

A technology for exhaust gas and biological deodorization, which is applied in separation methods, dispersed particle separation, and air quality improvement. Fast adsorption process, wide absorption and adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The plasma biological deodorization process and system of the exhaust gas from the steel barrel spraying production line of the present invention will be further described in detail below. It should be noted that the process and system are not limited to the deodorization process, and are applicable to the treatment of various waste gases, especially the waste gas produced by the steel barrel spraying production line.

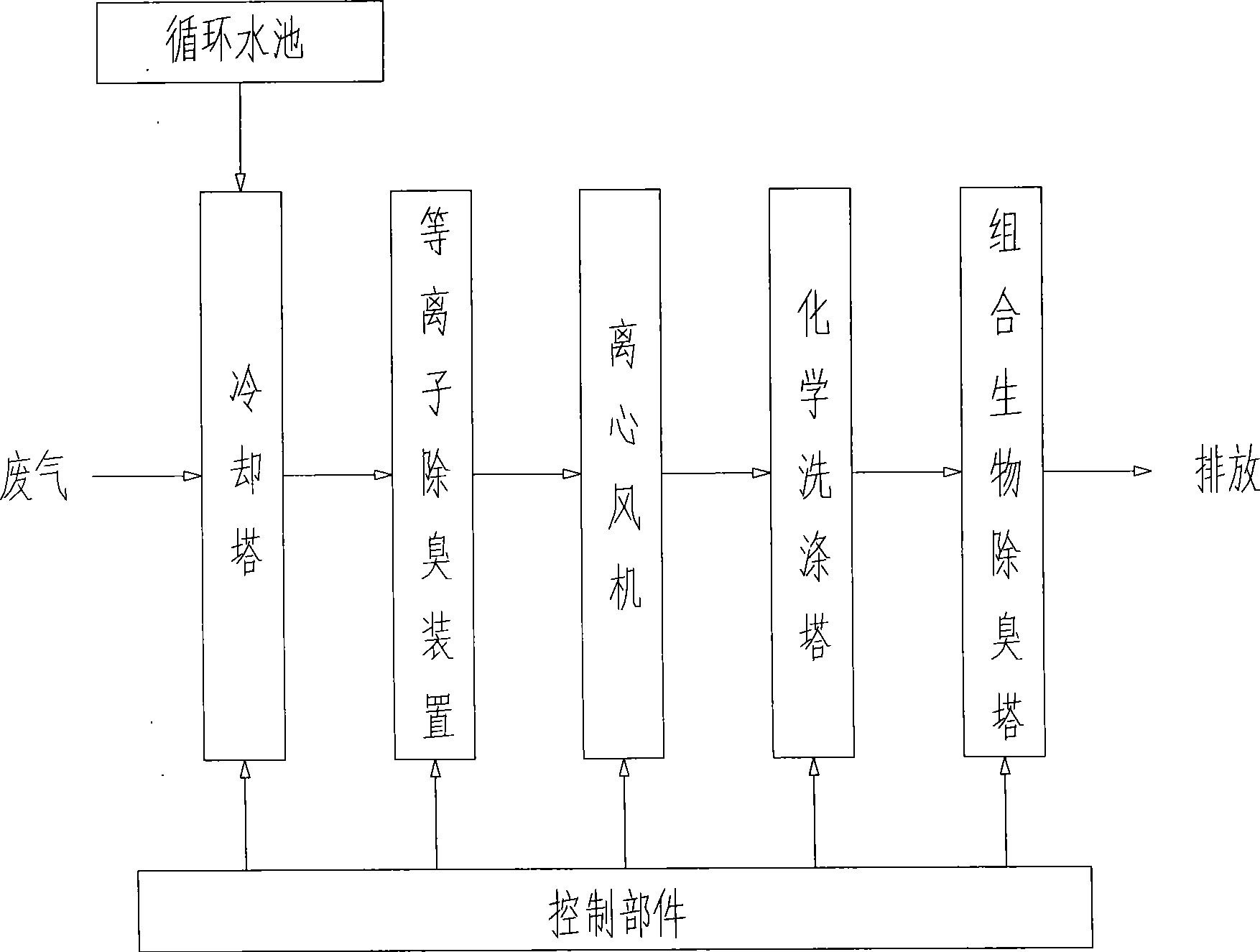

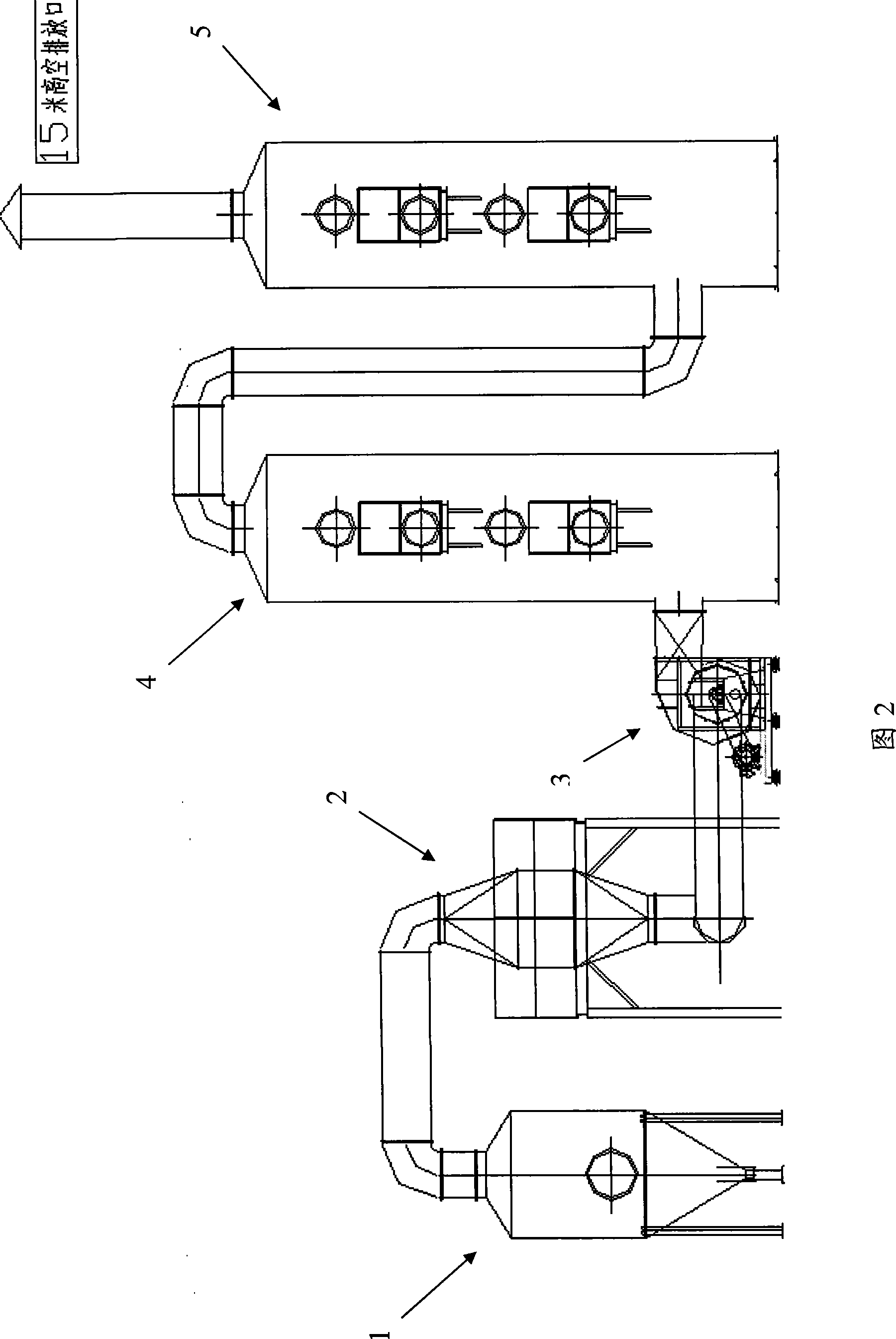

[0018] See figure 1 And Fig. 2, the plasma biological deodorization system of steel drum spraying production line discharge gas of the present invention comprises: pool, cooling tower 1, plasma deodorization device 2, centrifugal fan 3, chemical washing tower 4, combined biological deodorization tower 5 and control parts etc.

[0019] The water pool is arranged near the cooling tower 1 , which can be a concrete structure, and is used to provide the cooling water required by the cooling tower 1 . At the same time, a floating ball is arranged in the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com