Sewage water and sludge co-processing emission-reducing process and system

A technology of co-processing and sludge, applied in biological sludge treatment, aerobic and anaerobic process treatment, etc., can solve the problems of low degree of sludge stabilization treatment, inconvenient operation and management, and insignificant income, and achieve investment and operation. Cost reduction, reduction of secondary pollution, reduction of reaction time and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

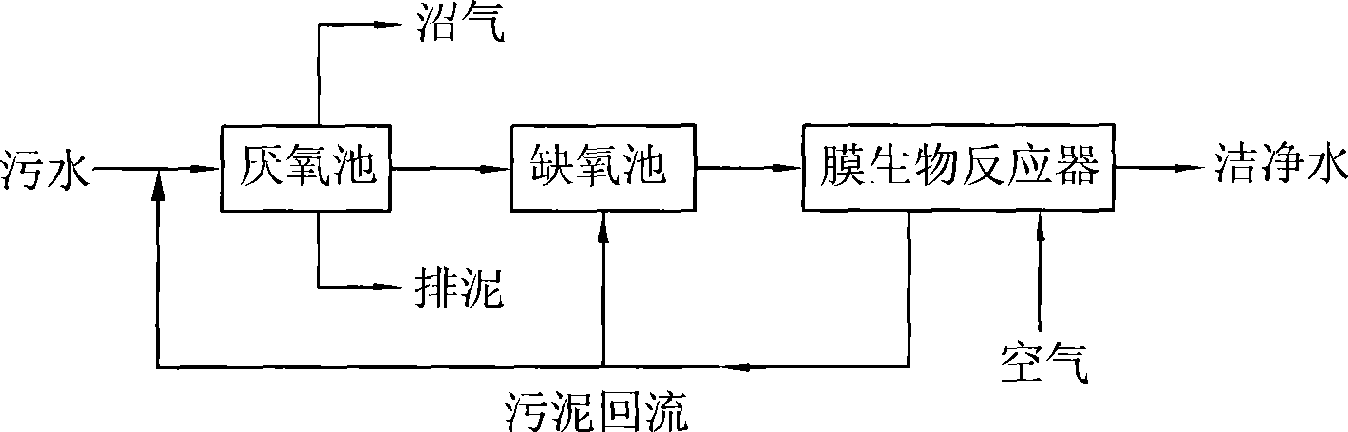

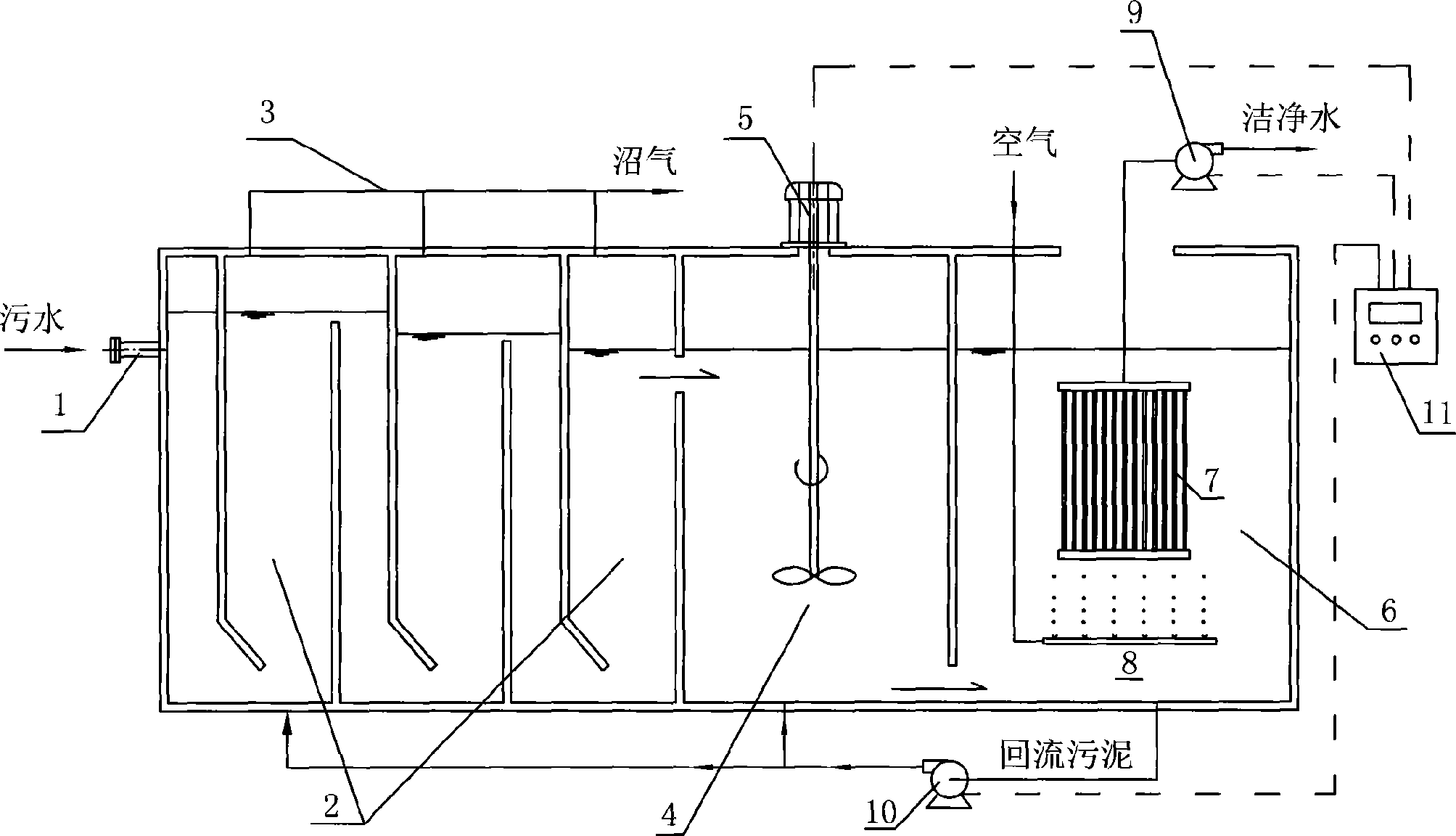

[0018] Such as Figure 1 ~ Figure 2 A sewage and sludge treatment emission reduction process and system shown in the figure are mainly composed of three parts: anaerobic reactor, anoxic reactor and aerobic membrane bioreactor. The auxiliary equipment includes anoxic zone mixer, sludge Backflow pump, membrane bioreactor outlet pump and automatic control device. The pool body can be made of materials such as concrete, PVC and glass fiber reinforced plastics, depending on specific requirements. The aerobic membrane bioreactor is provided with an excess sludge discharge port, and the aerobic nitrification sludge mixture is returned to the return port of the anaerobic reactor and the anoxic reactor through a sludge return pump. The effective volume of anaerobic reactor, anoxic reactor and membrane bioreactor is determined by the treatment object, and the hydraulic retention time corresponds to the effective volume of each part. For wastewater with good biodegradability (COD below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com