Highly effective complete aluminum alloy heat exchanger

An aluminum alloy heat exchanger technology, which is applied in the field of high-efficiency all-aluminum alloy heat exchangers, can solve the problems of large fluid resistance, excessive flow rate, and easy leakage, so as to improve the total heat transfer coefficient, reduce equipment costs, increase The effect of large heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

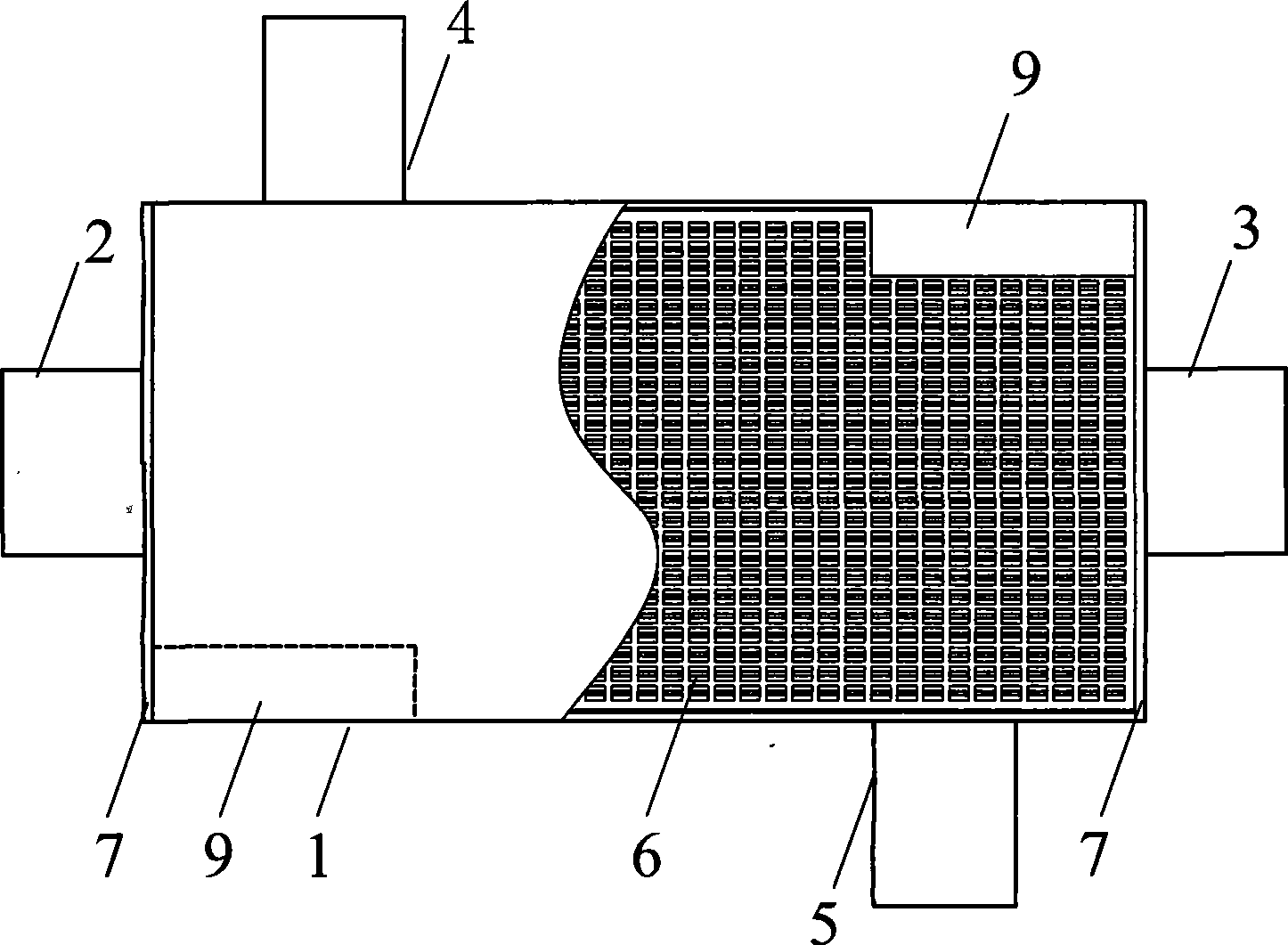

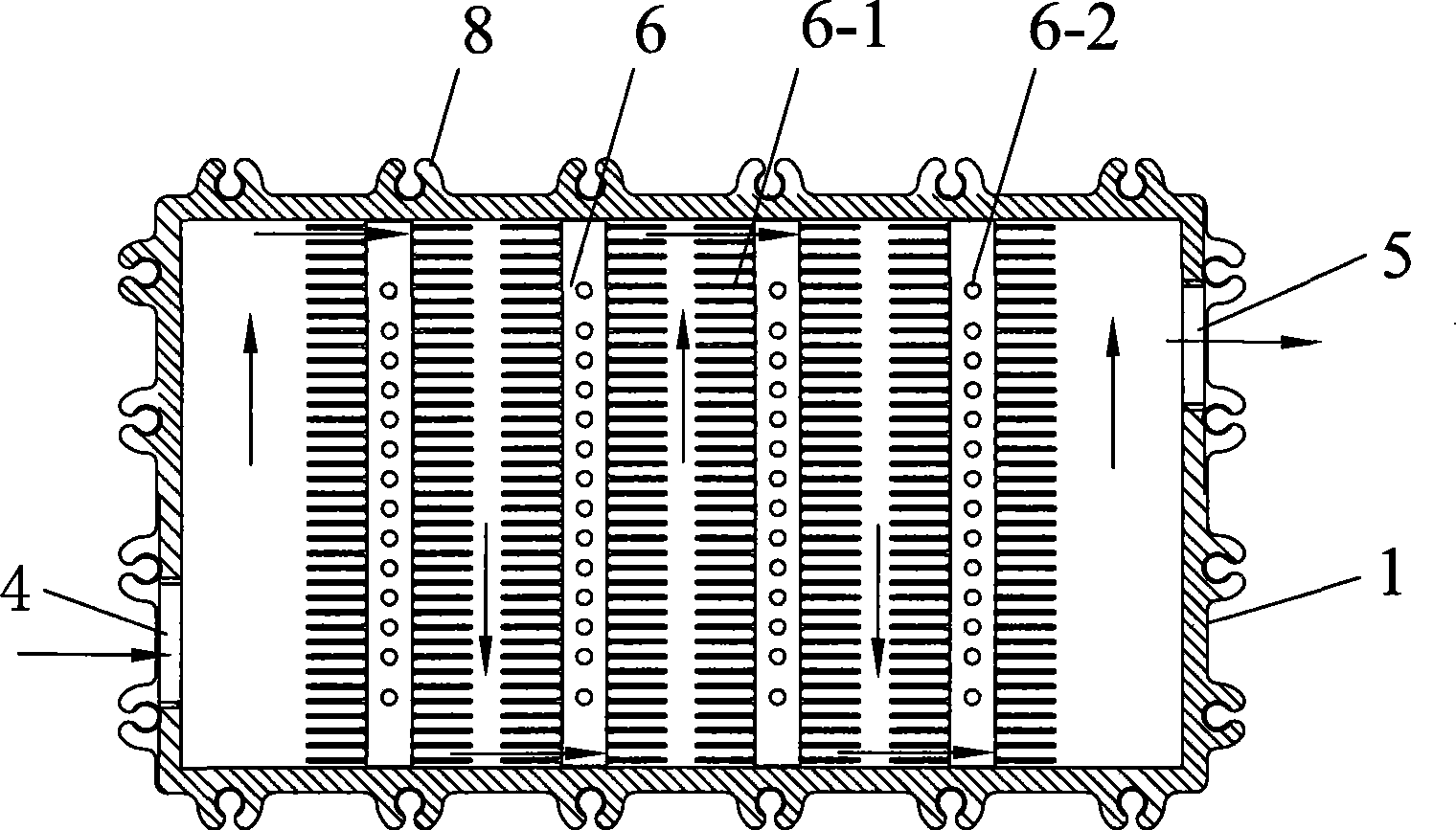

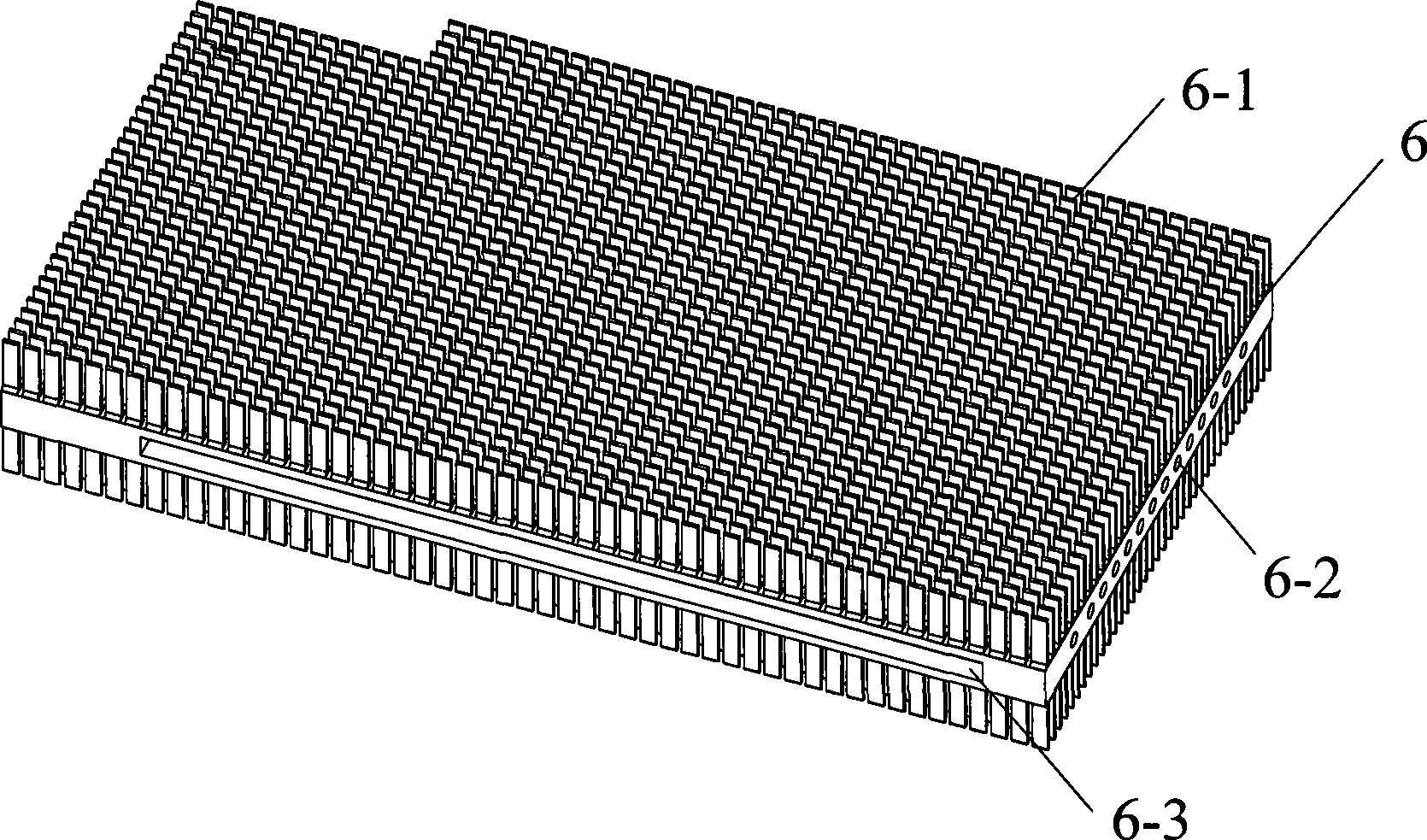

[0024] See Figure 1-4 , a high-efficiency all-aluminum alloy heat exchanger of the present invention, which is composed of a cuboid shell 1 and main fluid inlet and outlet pipes 2, 3 connected outside the shell, and heat exchange medium inlet and outlet pipes 4, 5. The housing 1 has at least one all-aluminum alloy heat exchange fin 6 integrally formed by extrusion process, and the plurality of heat exchange fins 6 are installed parallel to each other and arranged at a certain distance; generally, the housing 1 is in the shape of a cuboid; 1. There are two kinds of flow channels: the first flow channel is the main flow channel, and the main fluid enters and exits the main flow channel under high pressure; the other flow channel is the refrigerant or heat medium flow channel for heat exchange, which exchanges heat with the fluid in the main flow channel according to the process requirements To realize the vaporization or liquefaction of the main fluid.

[0025] The all-aluminu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com