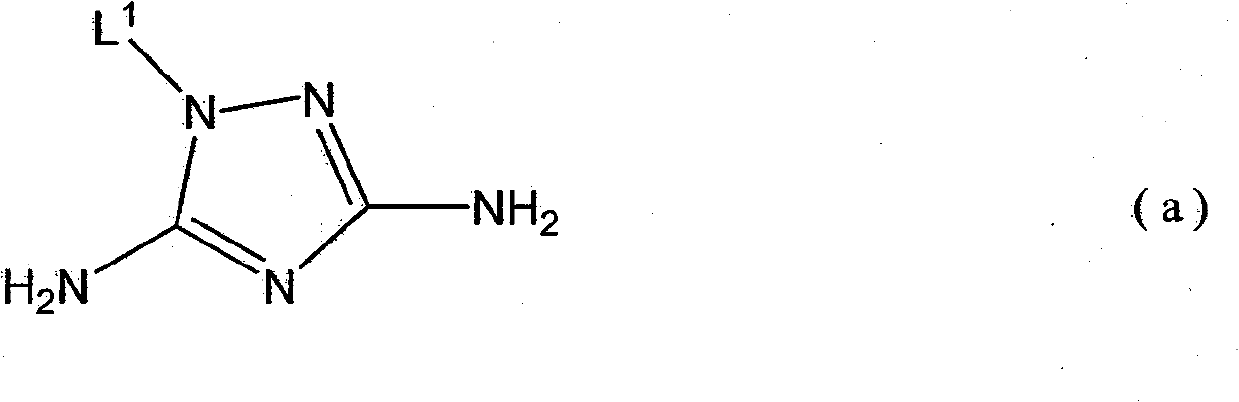

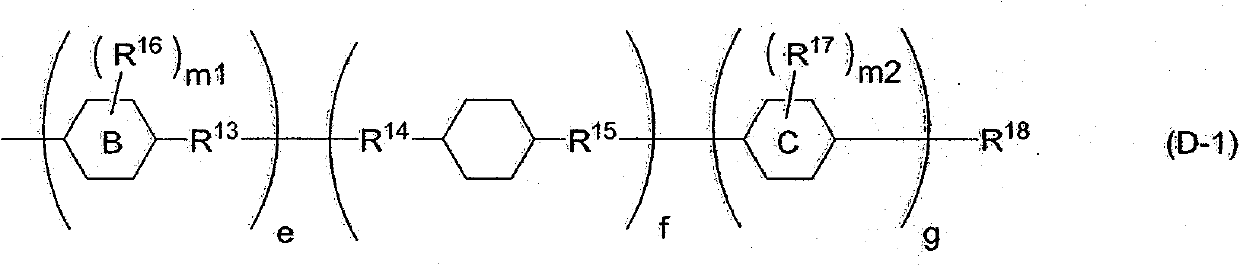

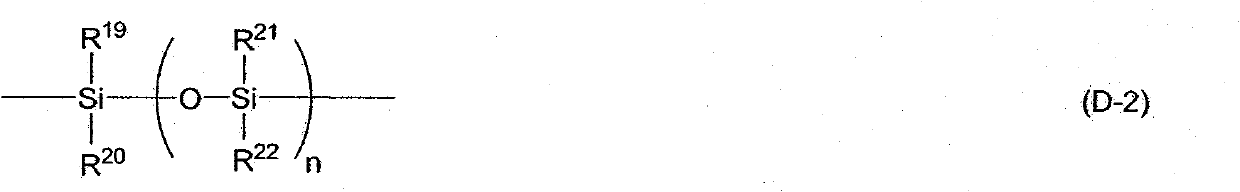

Liquid crystal oriented agent, liquid crystal oriented film and liquid crystal display element

A technology of liquid crystal alignment agent and polymer, applied in liquid crystal materials, optics, instruments, etc., can solve the problems of narrow image viewing angle, half-tone brightness inversion, brightness or contrast reduction, etc., and achieve low ion density and high voltage retention Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0242] Hereinafter, although an Example demonstrates in detail the liquid crystal aligning agent and liquid crystal display element obtained by using the polymer of this invention, this invention is not limited to these Examples. In the embodiments, GPC is used to measure the molecular weight, polystyrene is used as the reference solution, and dimethylformamide (DimethylFormamide, DMF) is used as the eluent. In addition, in the following examples, the unit liter of volume is represented by L. Thus, mL means milliliters.

[0243] The evaluation methods of the liquid crystal display elements used in the examples are shown below.

[0244] (1) Residual DC

[0245] After superimposing a DC voltage of 3 V on a rectangular wave of 3 V at 30 Hz for 30 minutes, the flicker cancellation voltage after 5 minutes was measured, and the absolute value of this value was defined as residual DC. The smaller the residual DC, the smaller the afterimage, and therefore it was considered good.

...

Synthetic example 1

[0277]

[0278] In a 100mL four-necked flask equipped with a thermometer, a stirrer, a raw material input port, and a nitrogen inlet, put 0.125g of compound (a-1), 2.26g of compound (V-1), and 24mL of dehydrated NMP, and dry Stir to dissolve under nitrogen flow. While keeping the temperature of the reaction system at 5°C, 1.24 g of compound (19) and 1.38 g of compound (1) were added and allowed to react for 30 hours, then 13 mL of BC and 28 mL of GBL were added to prepare a polymer component The concentration is 5wt% polyamic acid solution. In the reaction of the raw material, when the reaction temperature rises due to the heat of reaction, the reaction temperature is controlled to be about 70°C or lower to react.

[0279] In addition, in the examples of the present invention, the reaction was carried out while checking the viscosity during the reaction, and when the viscosity of the varnish after adding BC reached 30 mPa·s to 35 mPa·s (using an E-type viscometer; 25° C.) ...

Synthetic example 2~6

[0282]

[0283] Varnish A2-A6 was prepared by the method similar to synthesis example 1 except having changed tetracarboxylic dianhydride and diamine into the kind and mixing ratio (mol%) shown in Table 1, respectively. The molar ratio of the total amount of tetracarboxylic dianhydride to the total amount of diamine is 1. Table 1 shows the weight average molecular weight of the obtained polyamic acid.

[0284]

[0285]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com