Capacitor energy storage and capacitor energy storing device including the same

A technology of capacitive energy storage and energy storage, which is applied in the direction of fixed capacitor dielectrics, capacitors, electrolytic capacitors, etc., and can solve problems affecting the normal operation of capacitive energy storage, affecting surface heat dissipation, power loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

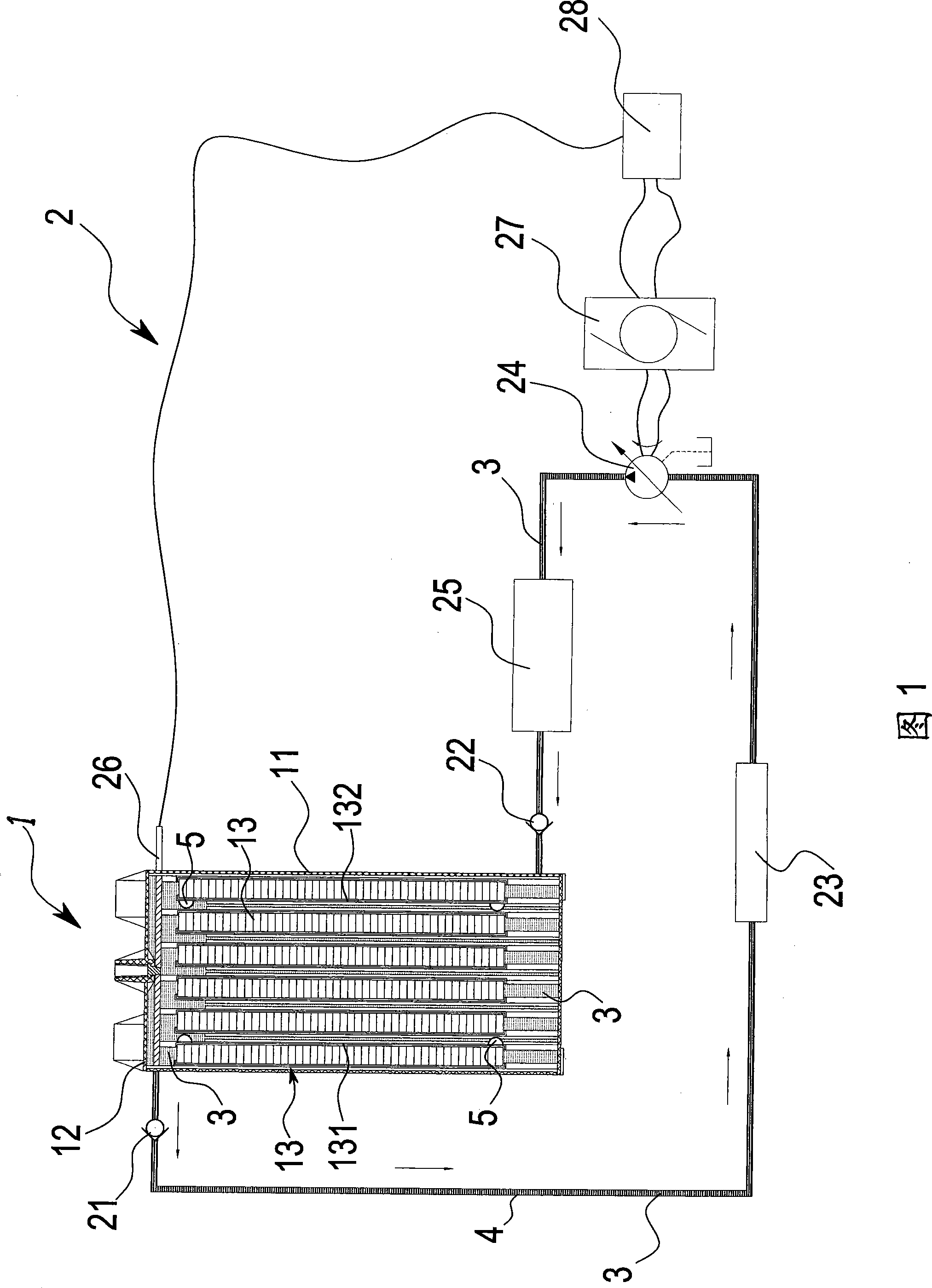

[0025] As shown in Figure 1:

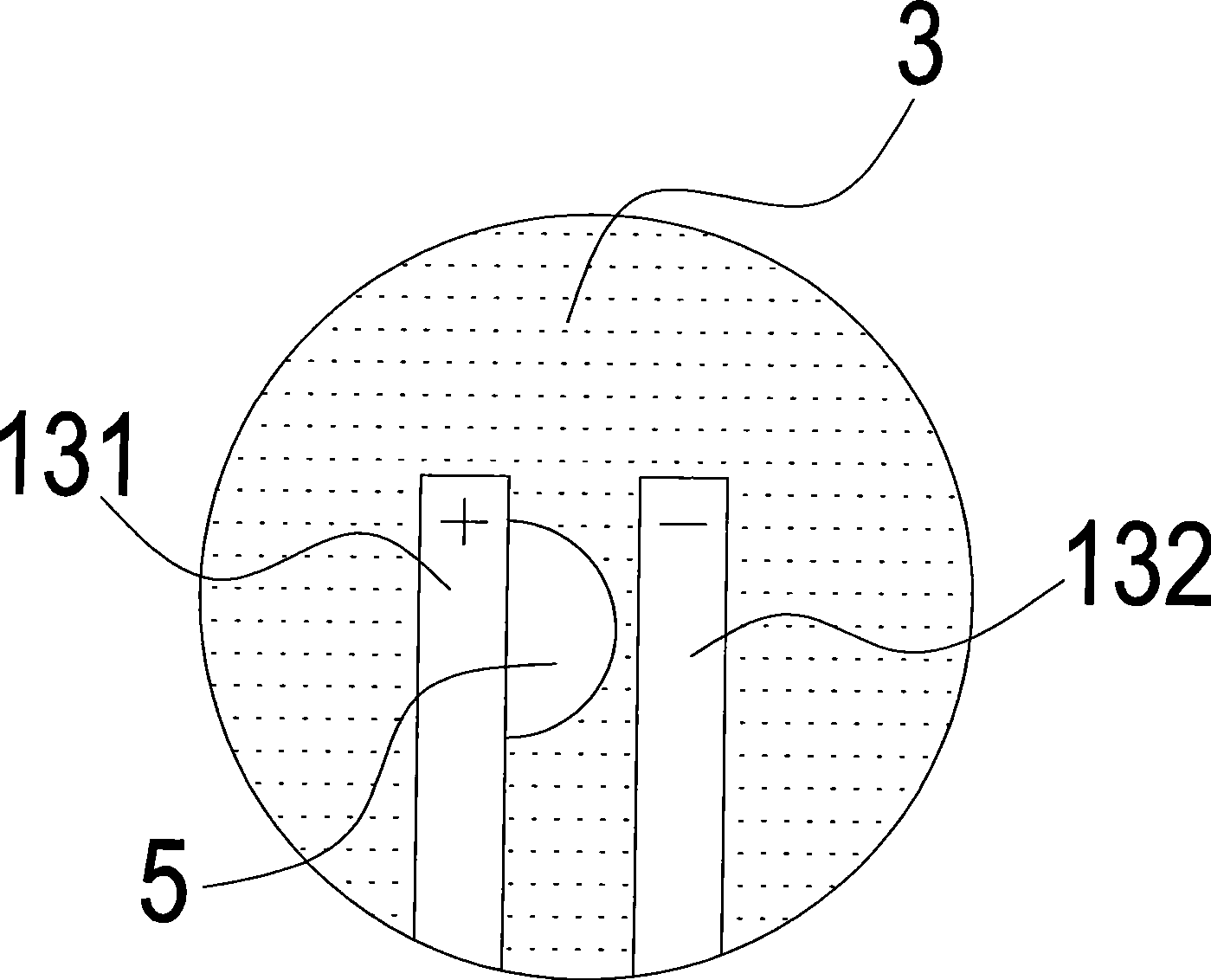

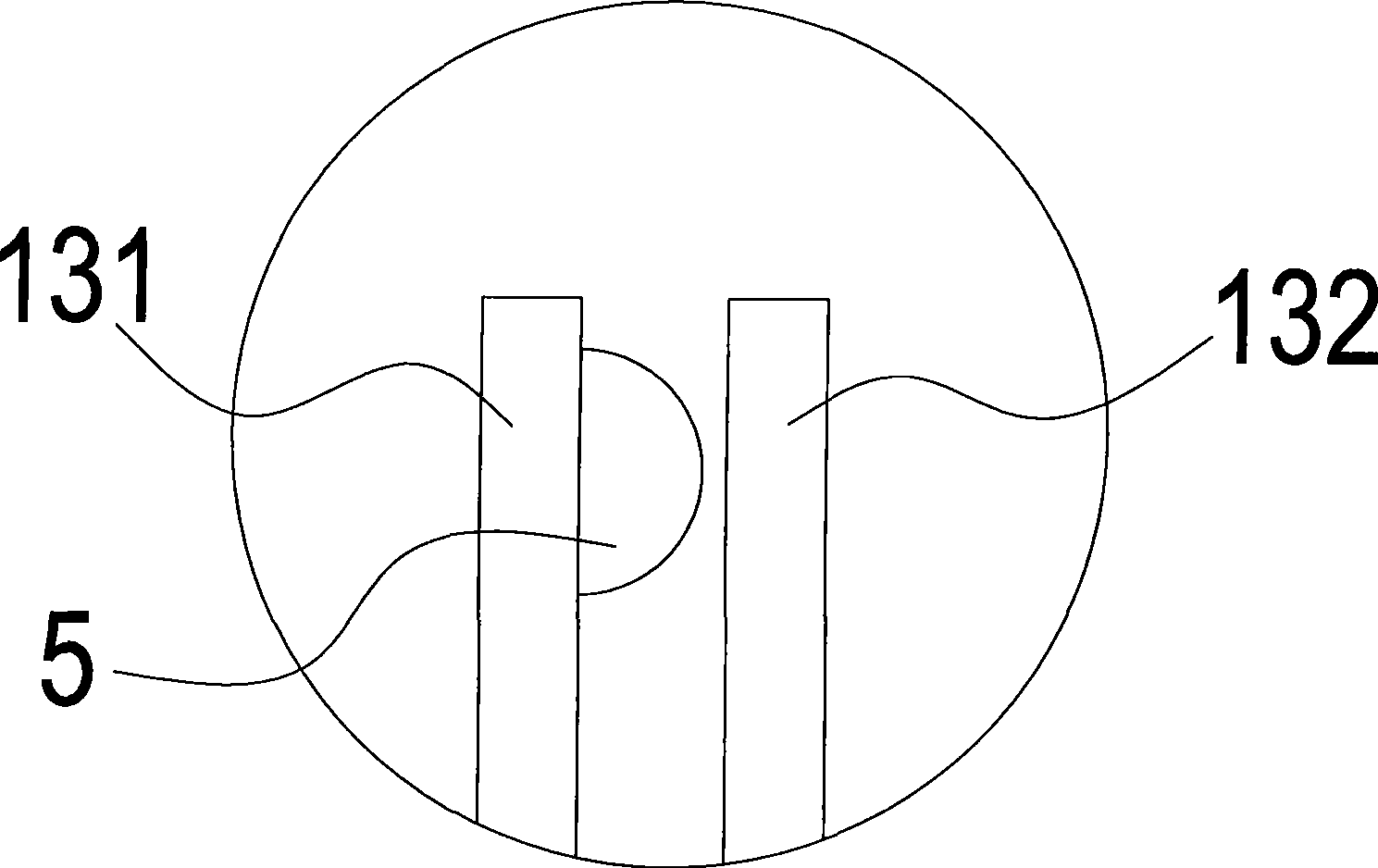

[0026] A capacitive energy storage device 1, which includes a box body 11, a box cover 12 sealed with the box body 11, a plurality of ceramic capacitor components 13 arranged in the box body 11, in the box body 11 is filled with silicone oil 3, and the dielectric strength of the silicone oil 3 is greater than 20KV / mm.

[0027] A capacitive energy storage device, which comprises a capacitive energy store 1 and a temperature-controlled circulation device 2 connected to the capacitive energy store, and the temperature-controlled circulatory device 2 includes a one-way valve (21, 22), a heating Or cooling device 23, one-way pressure pump 24, gas-liquid separation device 25, thermocouple 26, motor 27 and temperature controller 28, described one-way valve 21, heating or cooling device 23, one-way pressure pump 24, gas The liquid separation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com