Method for preparing sodium silicate from fluorine-containing silica gel

A technology of sodium silicate and silica gel, applied in the direction of silicate, alkali metal silicate, etc., can solve the problems of difficult recovery of fluorine, difficult to obtain products, difficult reaction, etc., and achieves low cost, good reactivity and high quality. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

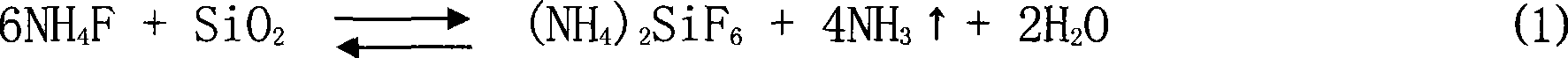

Method used

Image

Examples

Embodiment 1

[0021] (1) Dissolution of fluorine-containing silica gel: In the first dissolution kettle with a stirring and heating device, continuously add fluorine-containing silica gel (SiO 2 Content 20%, F - content 8.0%, 650kg / h) and ammonium fluoride solution (weight concentration 30%, 2360kg / h); the slurry overflows into the second dissolution kettle with stirring and heating device, the first dissolution kettle and the second dissolution kettle Keep the slurry boiling for a total residence time of 2 hours;

[0022] (2) Preparation of active silica: the ammonium fluorosilicate solution in the second dissolution kettle directly overflows to the first precipitation kettle with a cooling jacket, and the released from the first dissolution kettle and the second dissolution kettle during the dissolution process, The ammonia condensed and dewatered by the condenser is also passed into the first precipitation tank, the temperature of the slurry in the precipitation tank is controlled at 50...

Embodiment 2

[0026] (1) Dissolution of fluorine-containing silica gel: In the first dissolution kettle with a stirring and heating device, continuously add fluorine-containing silica gel (SiO 2 Content 34.32%, F - content 10.17%, 430kg / h) and ammonium fluoride solution (concentration 30%, 4000kg / h); the slurry overflows to the second dissolution tank with stirring and heating device, the first dissolution tank and the second dissolution tank Keep the slurry boiling for a total residence time of 1 hour;

[0027](2) Preparation of active silica: the ammonium fluorosilicate solution in the second dissolution tank directly overflows to the first precipitation tank with a cooling jacket, and the ammonia released from the dissolution tank during the dissolution process and condensed to remove water by the condenser It is also passed into the first precipitation tank, the temperature of the slurry in the precipitation tank is controlled at 60 °C, the slurry in the first precipitation tank overfl...

Embodiment 3

[0031] (1) Dissolution of fluorine-containing silica gel: In the first dissolution kettle with a stirring and heating device, continuously add fluorine-containing silica gel (SiO 2 Content 40%, F - content 12%, 210kg / h) and ammonium fluoride solution (concentration 20%, 3700kg / h); the slurry overflows to the second dissolution tank with stirring and heating device, the first dissolution tank and the second dissolution tank The slurry kept boiling with a total residence time of 1.1 hours;

[0032] (2) Preparation of active silica: the ammonium fluorosilicate solution in the second dissolution tank directly overflows to the first precipitation tank with a cooling jacket, and the ammonia released from the dissolution tank during the dissolution process and condensed to remove water by the condenser It is also passed into the first precipitation tank, the temperature of the slurry in the precipitation tank is controlled at 40°C, the slurry in the first precipitation tank overflow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com