Heaving movement compensation

A technology of motion compensation and heave compensation, which is applied in the direction of reducing ship motion equipment, transportation and packaging, hoisting devices, etc., can solve the problems of subsea equipment that limit the operating speed, achieve performance and efficiency improvement, and improve heave compensation devices Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

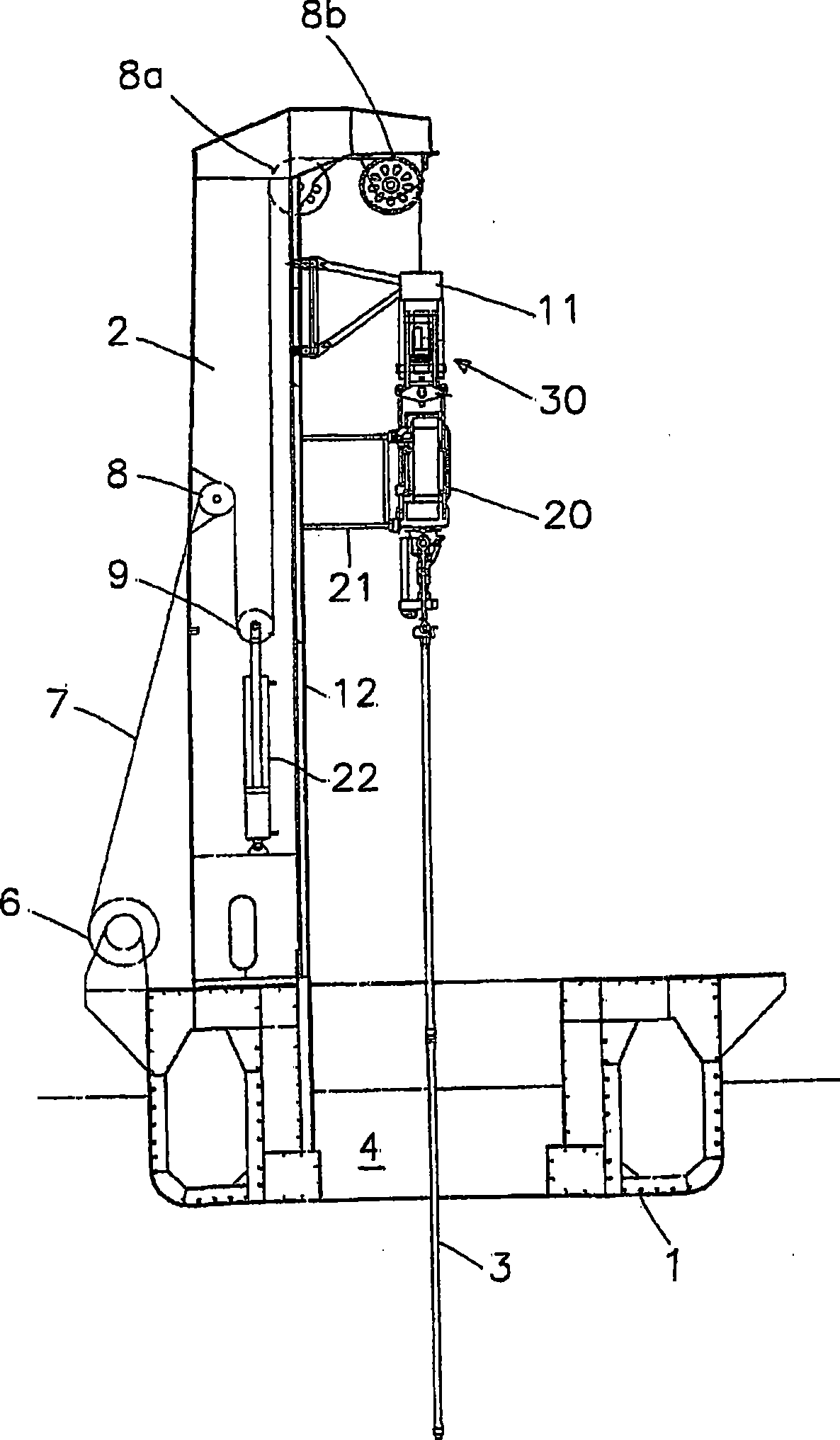

[0053] figure 1 Shown is a ship 1, here for the sake of illustration, an offshore drilling ship or an oil well handling ship, said ship 1 having a drilling structure 2 thereon on which a drill string 3 or other drilling pipes (such as risers) are drawn from said drilling structure. 2 hang into the sea. In this embodiment, the ship 1 is provided with a boat well 4 and the drilling structure is implemented as a derrick arranged in the vicinity of said boat well 4 .

[0054] The boat is equipped with a lifting device. In this embodiment a winch 6 is provided for paying out and taking in a cable 7 . The cable 7 is guided on pulley assemblies 8 , 8 a , 8 b , 9 in the structure 2 and on a pulley assembly 10 on a traveling block 11 . The trolley 11 is movable up or down relative to the structure 2 , here guided along one or more vertical rails 12 mounted on the mast 2 .

[0055] To carry out drilling operations, there is provided a top drive unit 20 which can support a drill stri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com