Method for producing hogwash fermented feed and special-purpose equipment thereof

A fermented feed and production method technology, applied in feed, animal feed, animal feed, etc., can solve the problems of difficult maintenance of equipment, high difficulty of control, high added value, etc., and achieve the effect of low cost, rich nutrition, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

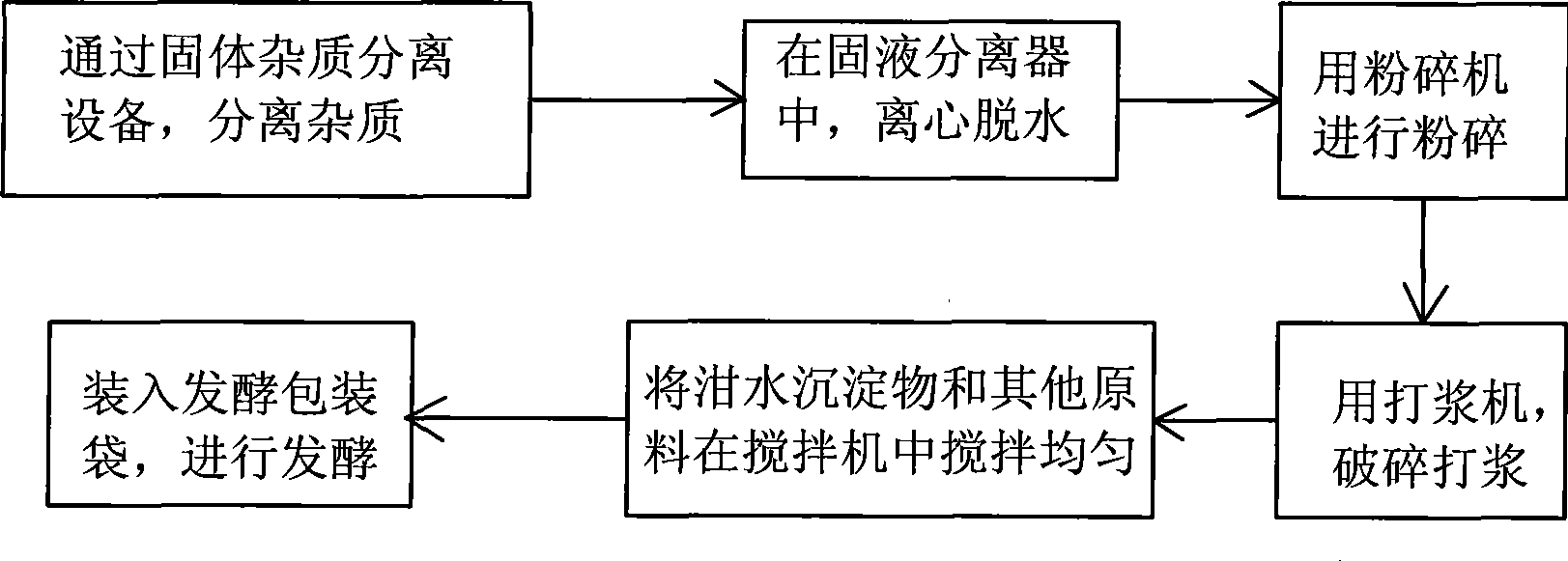

Method used

Image

Examples

Embodiment 1

[0040] (1) Separation of solid impurities

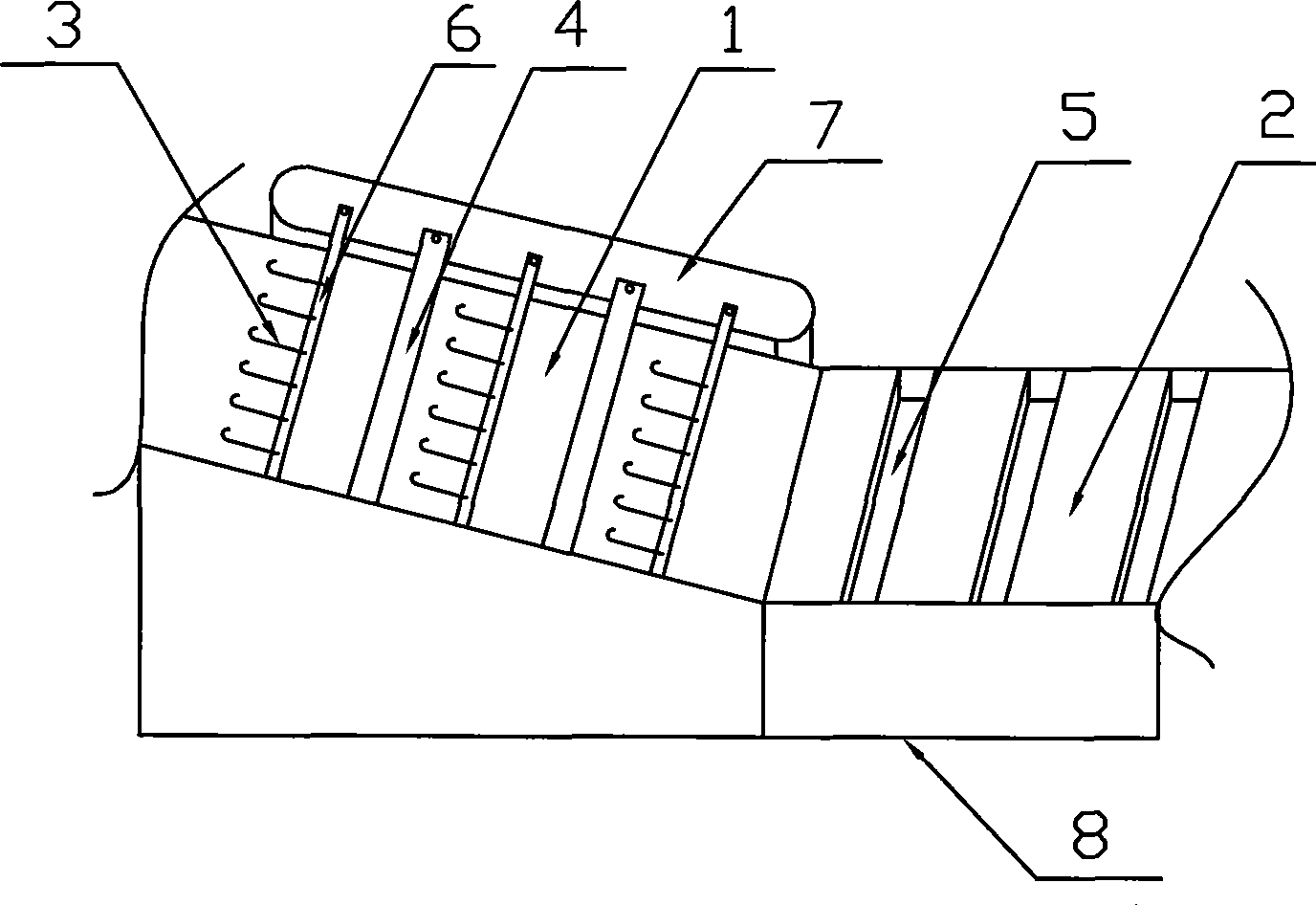

[0041] like figure 2 As shown, the solid impurity separation equipment includes a slant plate 1 and a flat plate 2, the lower end of the slant plate 1 is connected to one end of the plate 2, three rows of grabbing hooks 3 and two rows of magnets 4 are fixed on the sloping plate 1, and each row of grabbing hooks 3 And each row of magnets is set at 4 intervals. Three rows of grooves 5 are provided on the plate 2 . The inclined plate 1 and the flat plate 2 are located on the chassis 8 . The swill flows down from the upper end of the sloping plate 1, and automatically flows downward under the action of gravity. The grapple 3 can hook soft objects such as plastic bags, paper, ropes, and cloth, and the magnet 4 can absorb magnetic materials, while other large particles Heavy objects such as glass, hard plastics, etc. will fall into the groove 5 on the flat plate 2. The solid impurity separation equipment can remove the solid impuritie...

Embodiment 2

[0057] Only difference with embodiment 1 is step (4) and step (5), and others are all the same, and difference is as follows:

[0058] (4) Take the material in fresh animal offal under aseptic conditions, add sterile water to dilute 10 times, filter out 50 ml, take three 1 ml liquids, add sterile water to dilute, and dilute 10 times respectively 2 、10 3 、10 4 times, spread the diluted solution evenly on 3 solid mediums, each smearing 0.7ml. The culture medium was incubated at a temperature of 34°C for 5 days, and the number of colonies did not exceed 10 single colonies as the preselected strain. The pre-selected strains were expanded and cultivated in the nutrient solution for 22 hours to obtain the strain solution.

[0059] (5) prepare the swill fermented feed according to the raw materials specified in the following table 1 embodiment 2.

[0060] Pour each raw material into a blender and stir evenly, put it into a fermentation packaging bag, seal the mouth of the bag, an...

Embodiment 3

[0062] Only difference with embodiment 1 is step (4) and step (5), and others are all the same, and difference is as follows:

[0063] (4) Under aseptic conditions, take the material in fresh animal offal, add sterile water to dilute 10 times, filter out 50 ml, take 8 pieces of 1 ml liquid, add sterile water to dilute, and dilute 10 times respectively 2 、10 3 、10 4 、10 5 、10 6 、10 7 、10 8 、10 9 times, spread the diluted solution evenly on 8 solid media, each smearing 1.0ml. The medium was incubated at a constant temperature of 38°C for 4 days, and the number of colonies did not exceed 10 single colonies as the preselected strain. The pre-selected strains were expanded and cultivated in the nutrient solution for 24 hours to obtain the strain solution.

[0064] (5) prepare the swill fermented feed according to the raw materials specified in the following table 1 embodiment 3.

[0065] Pour each raw material into a blender and stir evenly, put it into a fermentation pack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com