Stabilization method and kneader system for flyash cement

A kneader and stabilization technology, which is applied in the field of fly ash cement stabilization and kneader systems, can solve problems such as high noise, insufficient automation of devices or equipment, poor anti-corrosion and wear-resistant treatment of kneaders, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

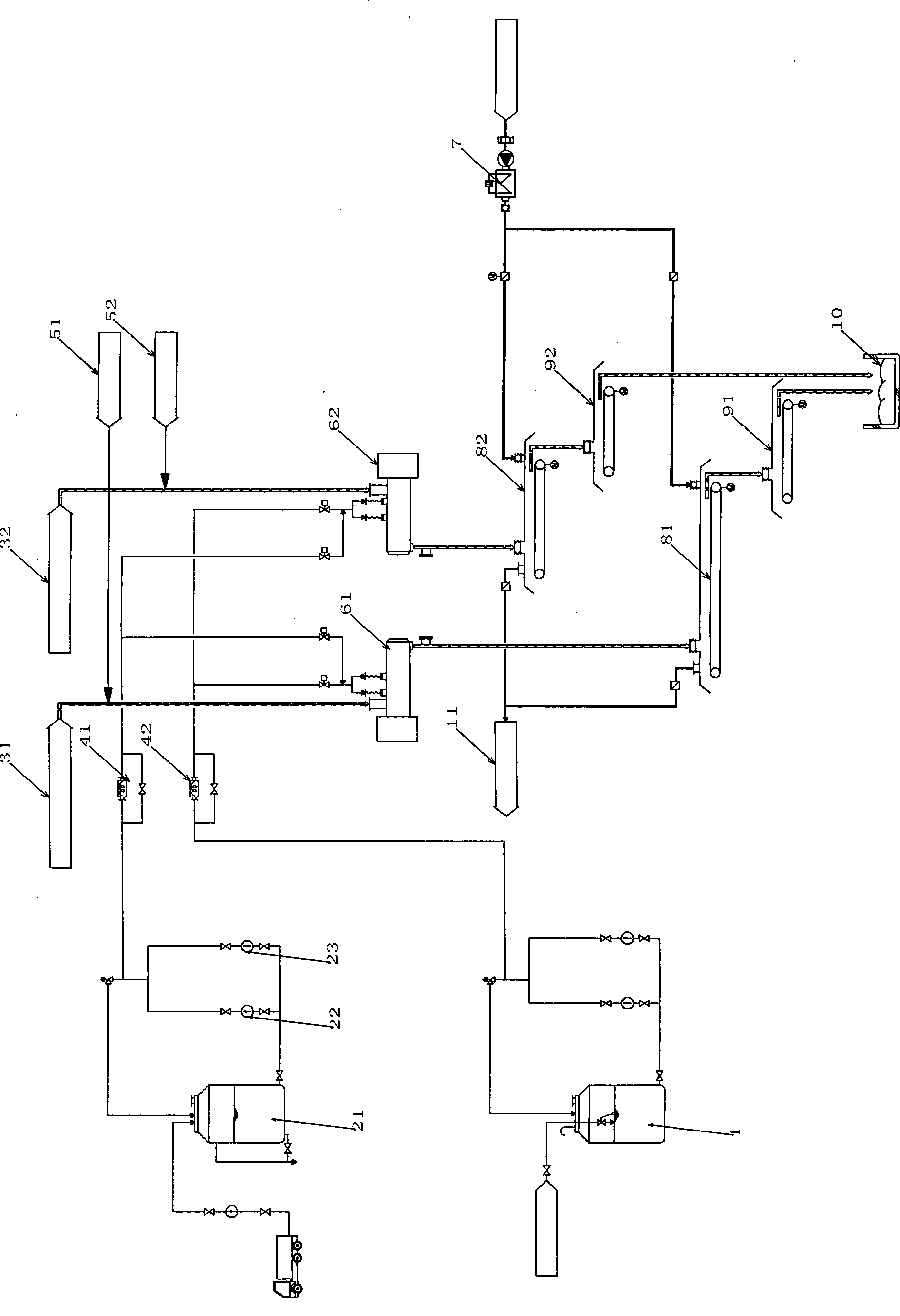

[0154] A method for stabilizing fly ash cement, comprising the following steps:

[0155] 1) Storage and transportation of fly ash and cement;

[0156] 2) Preparation of chelating agent and batching of materials;

[0157] 3) kneading and curing;

[0158] It is characterized by:

[0159] 1) The fly ash produced by flue gas purification is transported to the fly ash bin through the bucket elevator, and the bulk cement tanker blows the bulk cement to the cement silo through compressed air;

[0160] 2) The fly ash stabilization workshop is equipped with a fly ash conveyor, a chelating agent storage tank, a chelating agent injection pump, a water tank and an industrial water pump. The fly ash, chelating agent, water and cement are weighed according to the following setting ratio and sent to the kneader ;

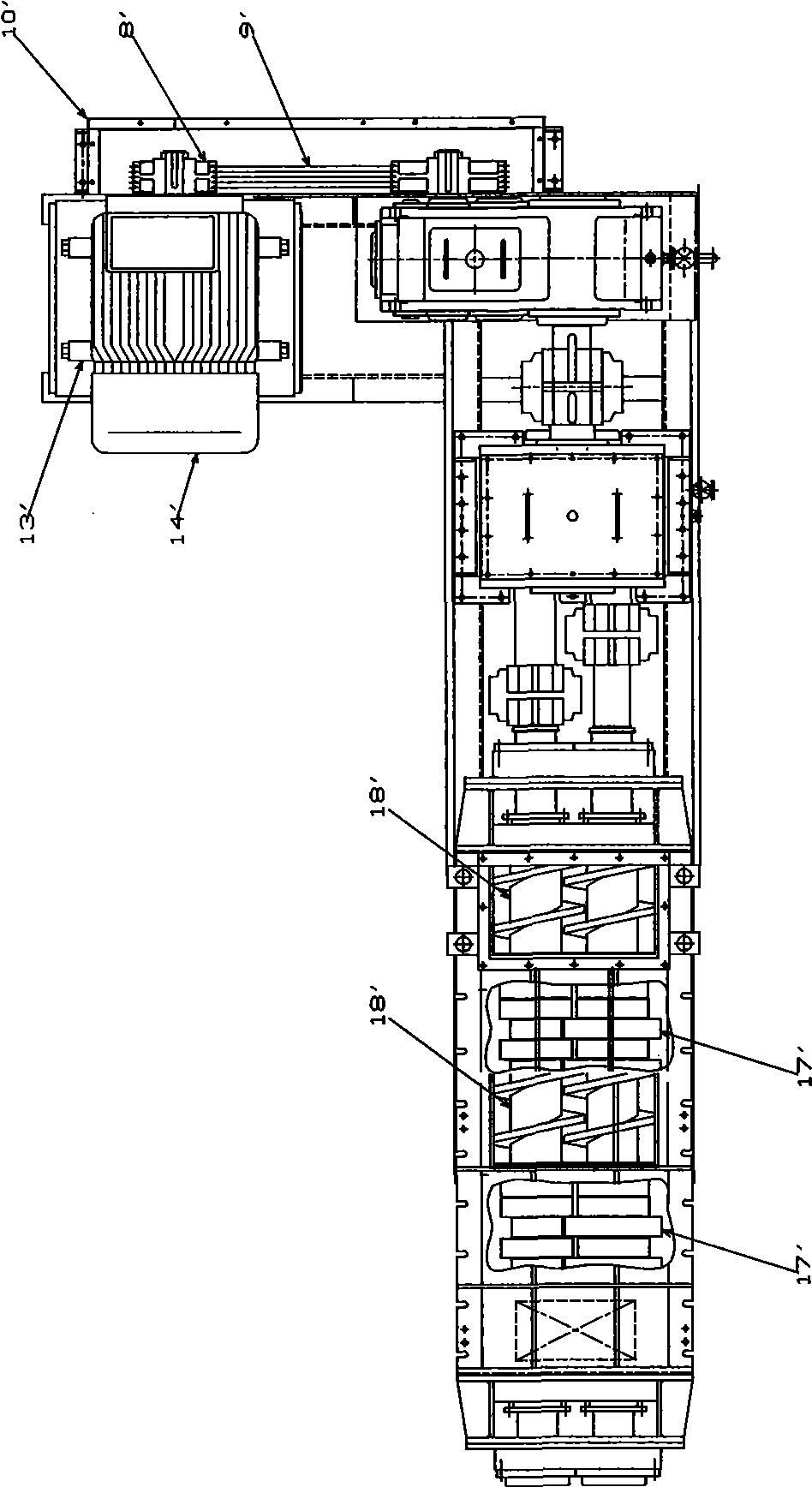

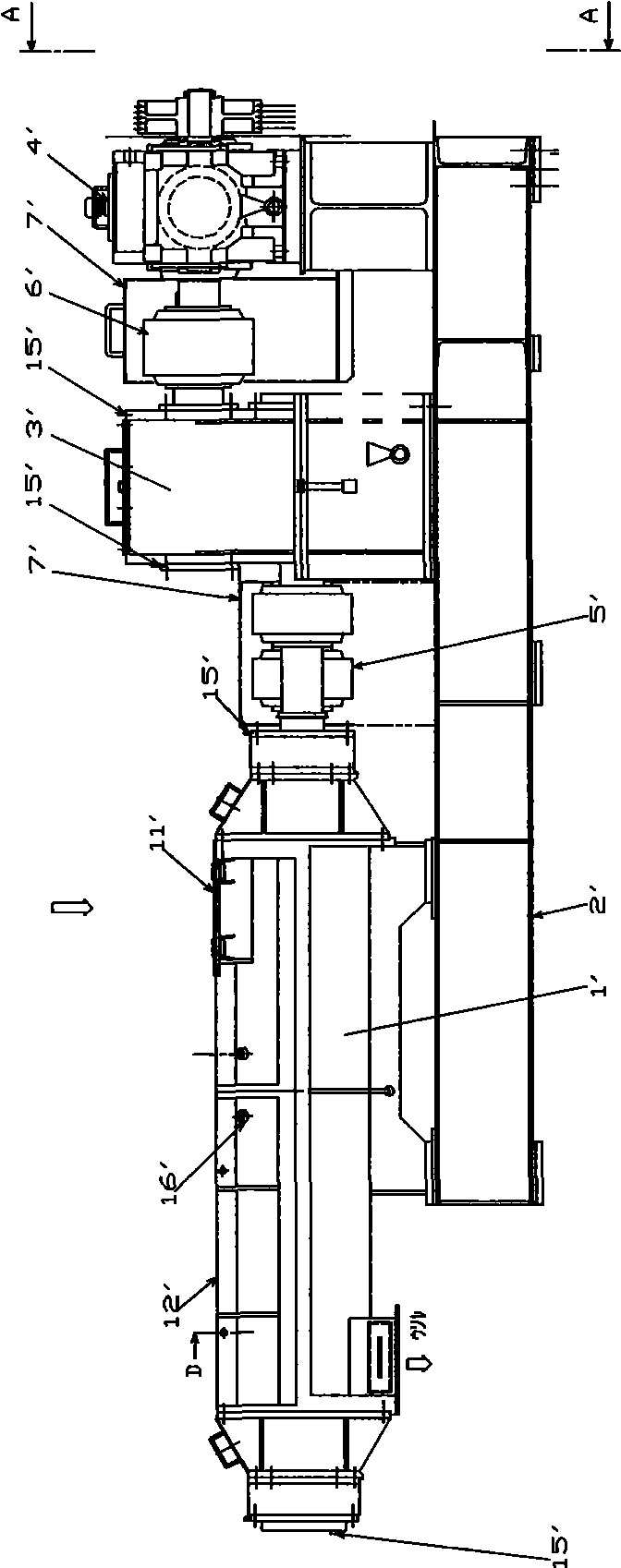

[0161] 3) The kneader is a horizontal double-shaft paddle type, and the kneader is forced to stir in the kneader. The stirring adopts the method of screw feeding or screw feed...

Embodiment 2

[0165] The method for stabilizing fly ash cement as described above is characterized in that:

[0166] Except for "tap water, cement and chelating agent or inorganic agent, the addition amount thereof is respectively: 35%, 12% and 4% of the weight of dry fly ash in % by weight", the rest is the same as the method described in Example 1.

Embodiment 3

[0168] The method for stabilizing fly ash cement as described above is characterized in that:

[0169] Except for "tap water, cement and chelating agent or inorganic agent, the addition amount thereof is respectively: 30%, 10% and 3% of the weight of dry fly ash in % by weight", the rest is the same as the method described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corner of repose | aaaaa | aaaaa |

| Bulk specific gravity | aaaaa | aaaaa |

| Corner of repose | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com