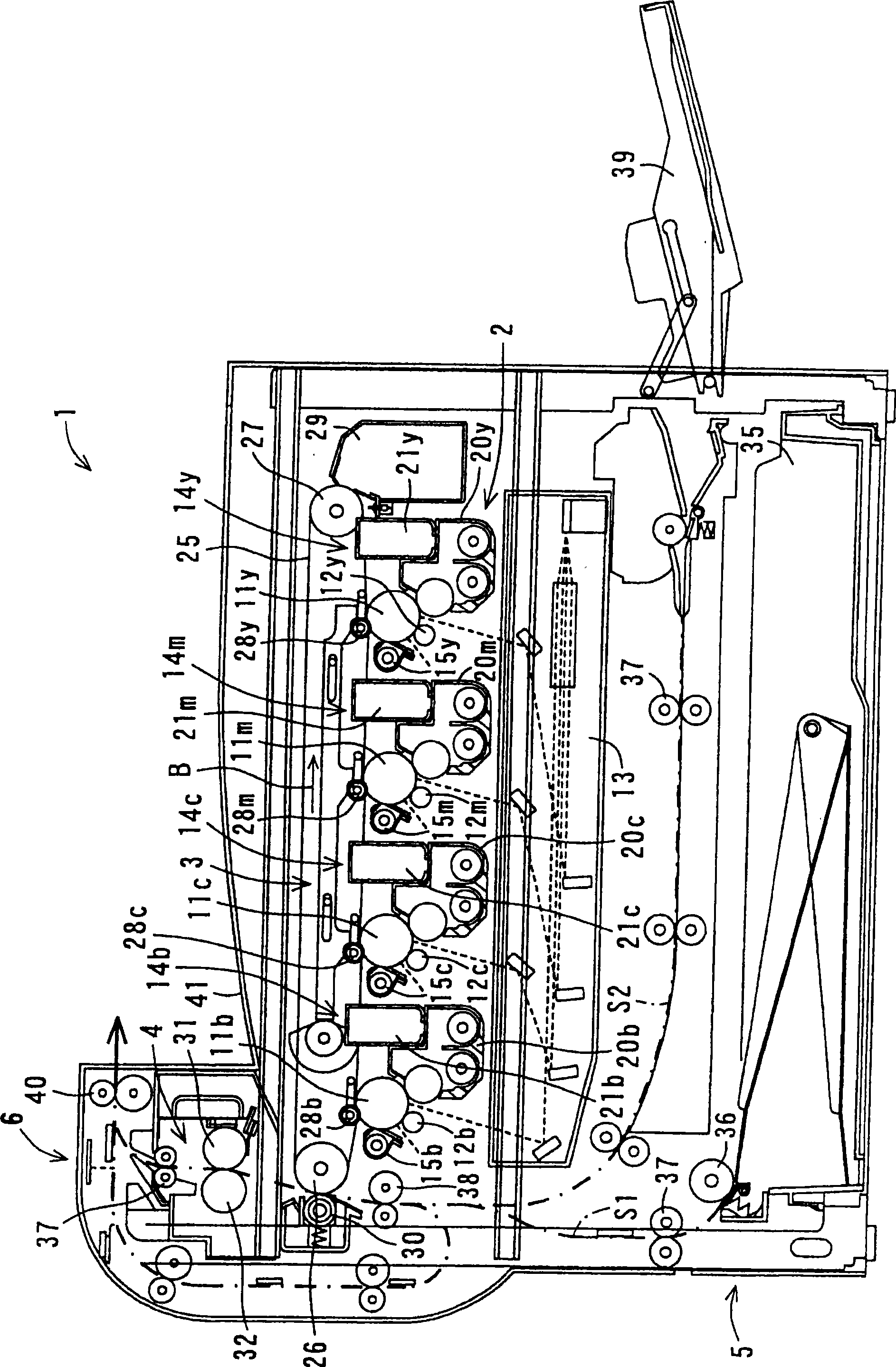

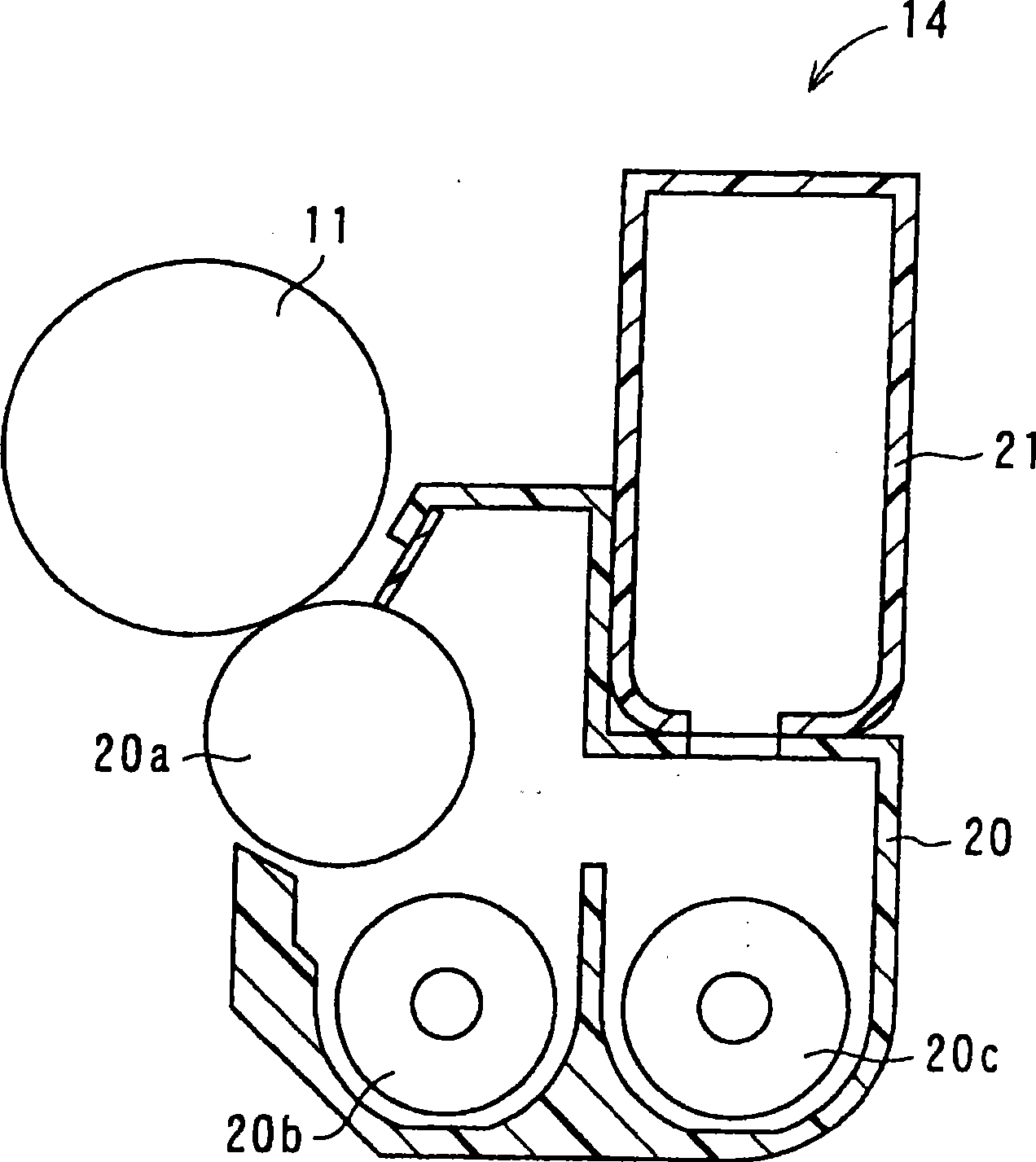

Toner, two-component developer, developing device, and image forming apparatus

A technology of toner and alumina, which is applied in the fields of developing devices and image forming devices, toners, and two-component developers, and can solve the problems of toner charging and color reproducibility, and long-term stability of charging Poor, crystalline polyester dispersion considerations and other issues, to achieve excellent low-temperature fixability, excellent charging uniformity, and the effect of solving global warming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

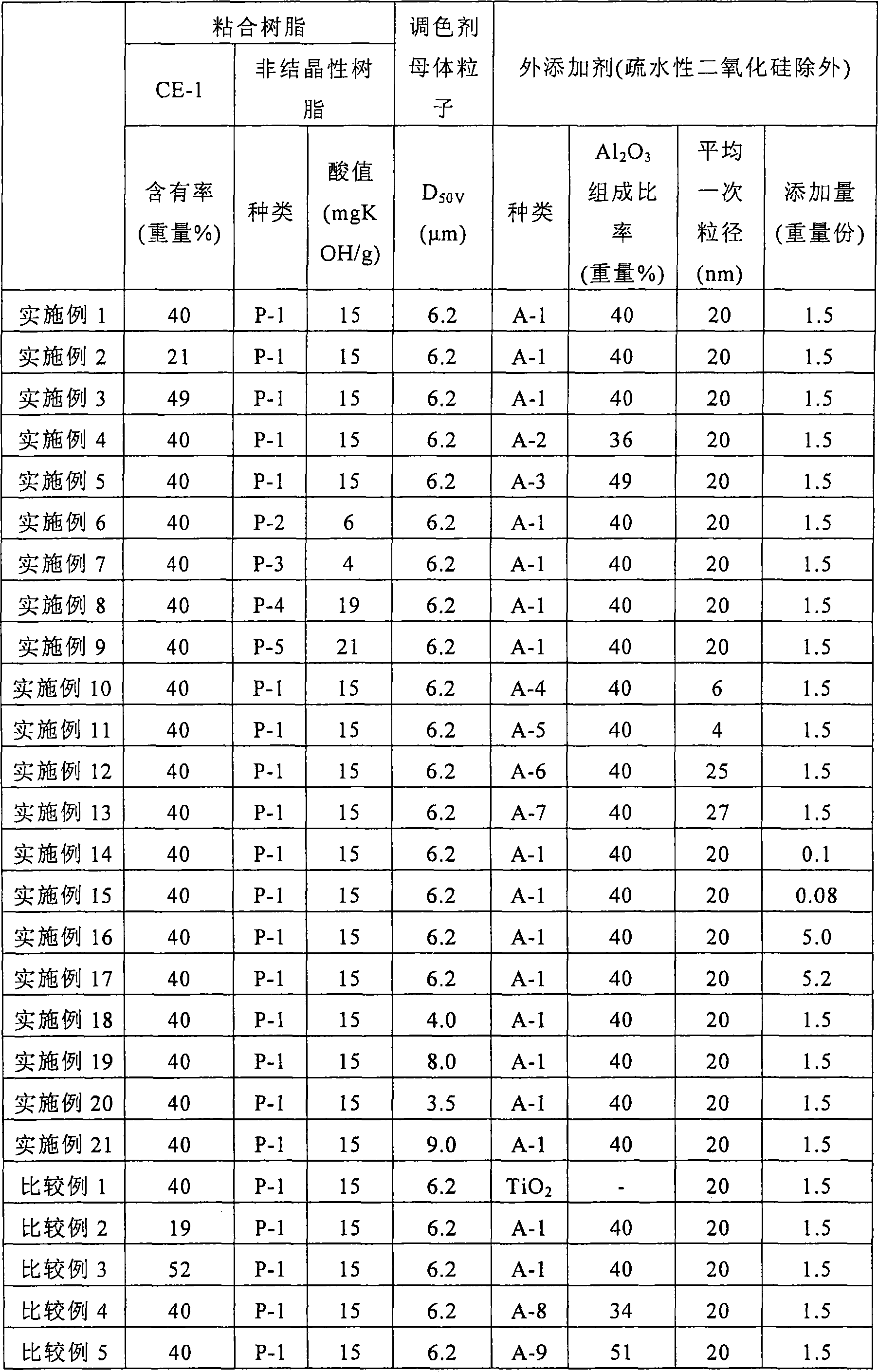

Embodiment 1

[0178] (Manufacture of toner matrix particles)

[0179] Using a Henschel mixer (trade name: FM20C, manufactured by Mitsui Mining Co., Ltd.), a mixture containing 40% by weight of polylactic acid copolymer (CE-1) and non-crystalline polyester (P-1, acid value: 15 mgKOH / g) 100 parts by weight of 60% by weight of binder resin, 5.0 parts by weight of copper phthalocyanine (colorant, C.I. 2.0 parts by weight of Orient Chemical Industry Co., Ltd.) and 4.5 parts by weight of paraffin wax (release agent, trade name: HNP10, manufactured by Nippon Seika Co., Ltd.) were uniformly mixed to obtain a mixture. Then, the obtained mixture was melt-kneaded while being heated with a twin-screw extrusion kneader (trade name: PCM-65, manufactured by Ikegai Co., Ltd.), and then cooled to room temperature to obtain a solidified product of the melt-kneaded product. .

[0180] The resulting melt-kneaded product was coarsely pulverized using a cutting mill (trade name: VM-16, manufactured by Orient ...

Embodiment 2

[0184] Except for using a binder resin containing 21% by weight of polylactic acid copolymer (CE-1) and 79% by weight of non-crystalline polyester (P-1), it was carried out in the same manner as in Example 1, and the preparation of Example 2 was produced. Toner. The volume average particle diameter of the obtained toner base particles was 6.2 μm.

Embodiment 3

[0186] Except for using a binder resin containing 49% by weight of polylactic acid copolymer (CE-1) and 51% by weight of non-crystalline polyester (P-1), it was carried out in the same manner as in Example 1, and the preparation of Example 3 was produced. Toner. The volume average particle diameter of the obtained toner base particles was 6.2 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com