Method for improving crisp property of freezing fermented deep-fried twisted dough sticks using transglutaminase

A technology of transglutaminase and crispness, which is applied in the field of food processing, can solve the problems of protein network structure destruction and crispness deterioration, and achieve the effects of low acrylamide content, improved crispness, and unique fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

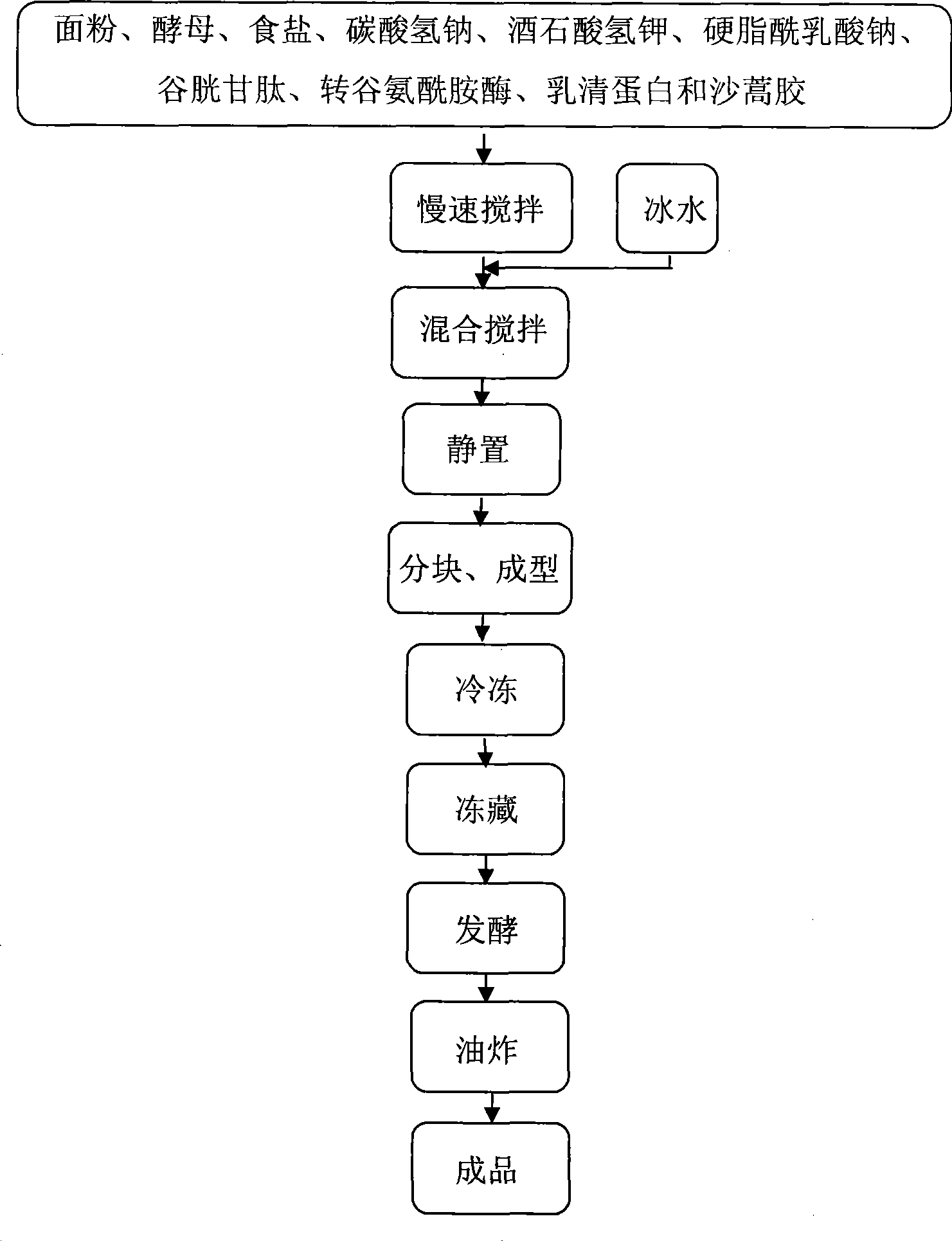

Image

Examples

Embodiment 1

[0018] Embodiment 1: A kind of transglutaminase of the present invention improves the method for crispiness of frozen fermented fried dough sticks, adopts the following process steps: its component ratio is counted by weight:

[0019] In the present invention, 58 parts of wheat flour, 2 parts of (live) yeast, 1 part of table salt, 0.8 part of sodium bicarbonate, 0.4 part of potassium hydrogen tartrate, 0.3 part of sodium stearoyl lactylate, 3.6 parts of glutathione, and 1 part of transglutamin Put 0.1 part of enzyme, 0.3 part of whey protein and 0.5 part of artemisia gum into the mixing tank, stir at a slow speed for about 30s, stirring speed: 50 rpm, mix all kinds of materials evenly, and then stir at a medium speed for 5min, the stirring speed : 210 rpm, stir and add 33 parts of ice water to form a dough; after the dough is formed, take it out, let it stand for 30 minutes, divide it into pieces (20g each), shape it (long strip), and wrap it with plastic wrap, then Freeze in ...

Embodiment 2

[0020] Embodiment 2: A kind of method of transglutaminase of the present invention improves the crispness of frozen fermented fried dough sticks, adopts the following process steps: its component ratio is calculated by weight parts:

[0021] In the present invention, 59 parts of buckwheat flour, 1.2 parts of (live) yeast, 1.5 parts of table salt, 1 part of sodium bicarbonate, 0.4 part of potassium hydrogen tartrate, 0.3 part of sodium stearoyl lactylate, 3 parts of glutathione, and 3 parts of transglutamin Put 0.3 parts of enzyme, 0.5 parts of whey protein and 1 part of artemisia gum into the mixing tank, stir at a slow speed for about 28s, stirring speed: 60 rpm, mix all kinds of materials, stir at medium speed for 4min, stirring speed: 200 rpm, stirring while adding ice water 32 to form a dough; after the dough is formed, take it out, let it stand for 28 minutes, divide it into pieces (20g), shape (long strips), wrap it with plastic wrap, and put it in a -37°C refrigerator F...

Embodiment 3

[0023] Embodiment 3: A kind of method of transglutaminase of the present invention improves the crispness of frozen fermented fried dough sticks, adopts the following process steps: its component ratio is counted in parts by weight:

[0024] In the present invention, 58.5 parts of oat flour, 1.5 parts of (live) yeast, 0.8 part of table salt, 1.2 parts of sodium bicarbonate, 0.6 part of potassium hydrogen tartrate, 0.5 part of sodium stearoyl lactylate, 3.5 parts of glutathione, and transglutamin Put 0.1 part of enzyme, 0.3 part of whey protein and 0.5 part of Artemisia gum into the mixing tank, stir at a slow speed for about 32s, stirring speed: 70 rpm, mix all kinds of materials, stir at medium speed for 6min, stirring speed: Stir at 180 rpm, add 32.5 parts of ice water at the same time to form a dough; after the dough is formed, take it out, let it stand for 32 minutes, divide it into pieces (20g), shape it (long strip), wrap it with plastic wrap, and store it at -39°C Freez...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com