Purification method for yellow phosphorus exhaust gas and device thereof

A yellow phosphorus tail gas and purification device technology, which is applied in chemical instruments and methods, separation methods, and separation of dispersed particles, etc., can solve problems such as aggravated atmospheric pollution, small production capacity, and shortened equipment life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

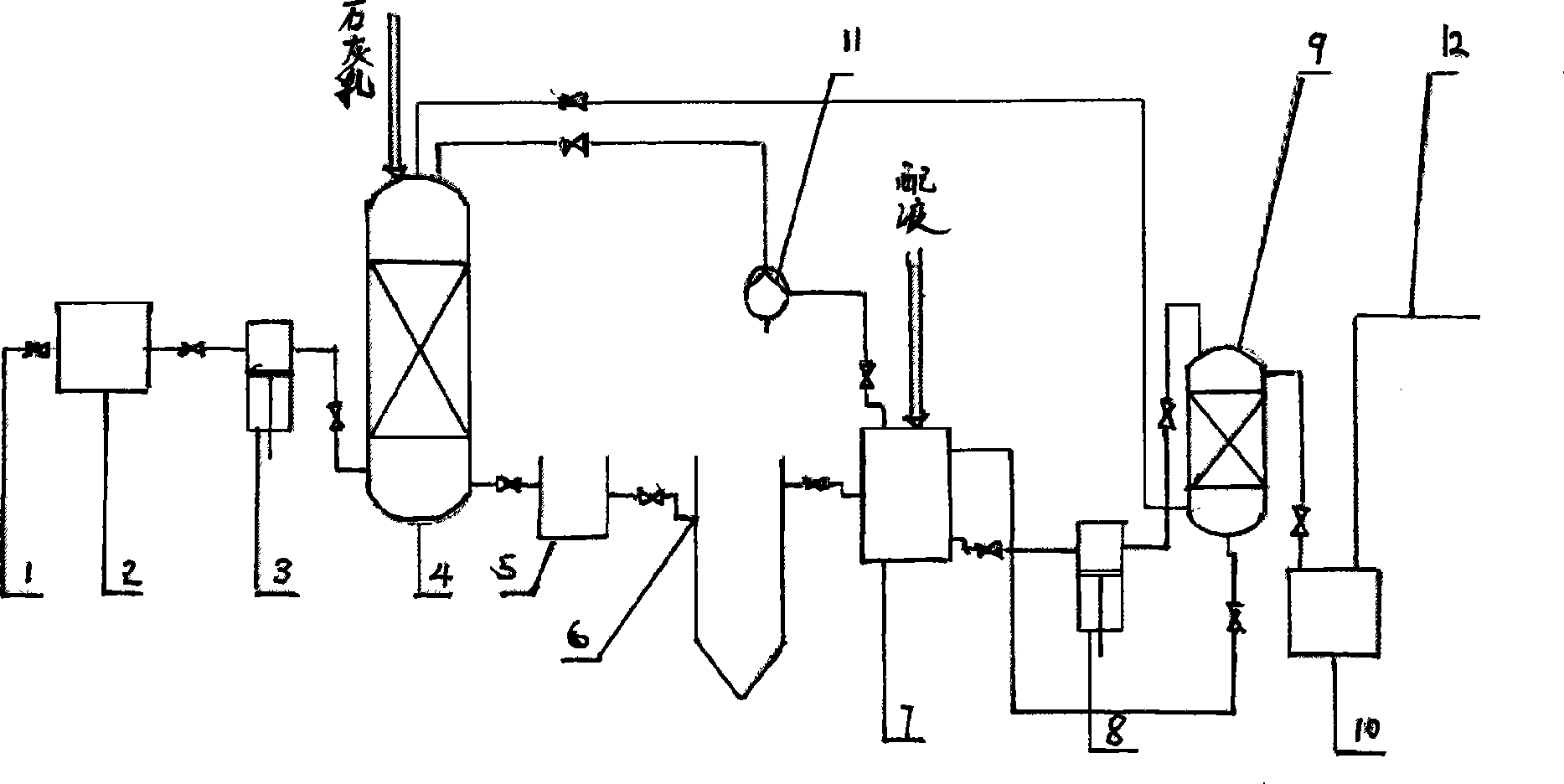

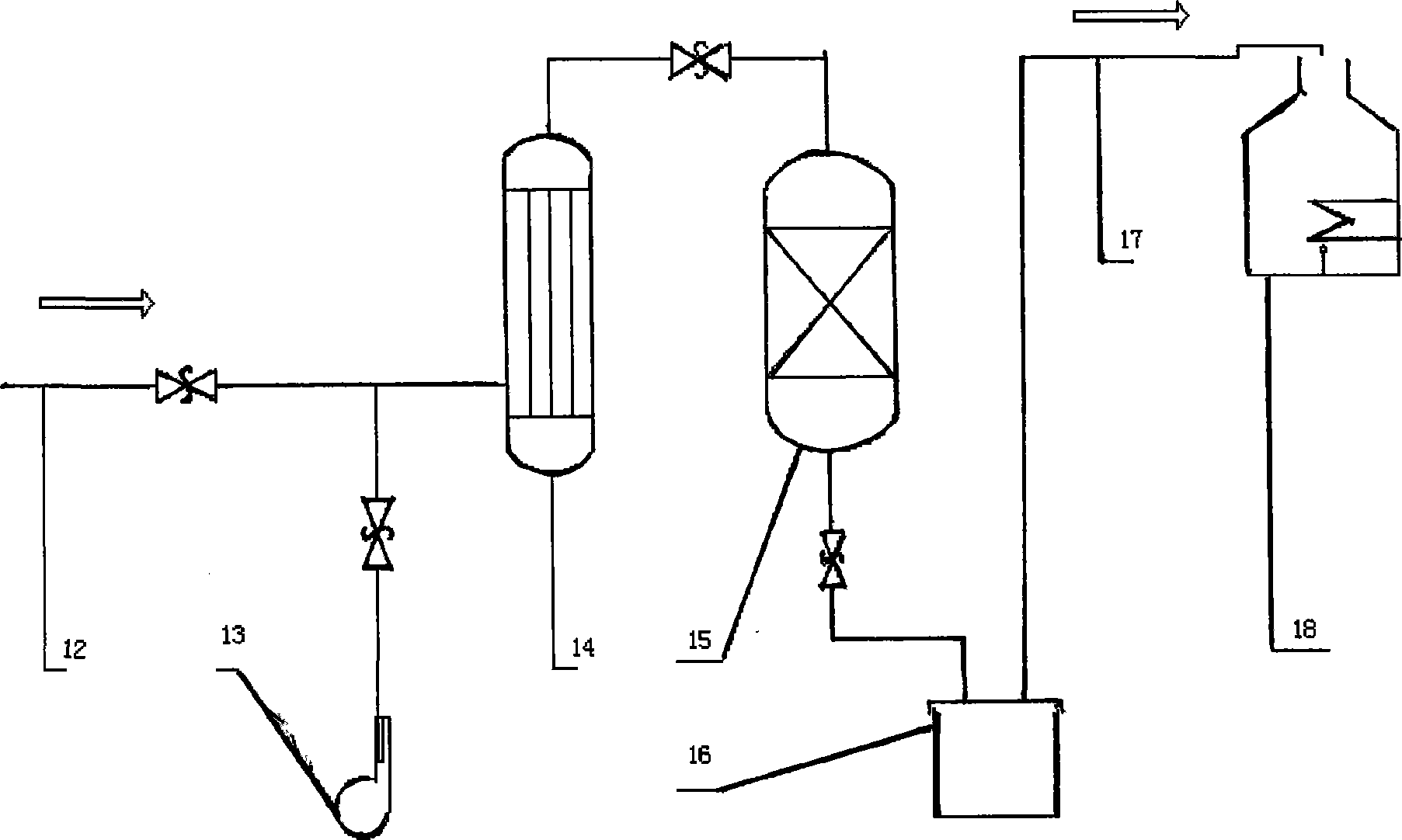

[0052] Embodiment 1: the gas volume of yellow phosphorus tail gas is 100Nm 3 / h. Through the safety water seal, use the primary washing pump to pressurize to 0.3MPa, calculate according to the lime with a purity of 80%, add 3kg of lime, add circulating water to the water level line of the lime emulsion, open the primary washing turbulence tower, and perform sufficient washing. The dust entrained by the yellow phosphorus tail gas is removed, and the washed sewage is put into the collection tank (5), and precipitated in the sedimentation tank (6), and the precipitated CaF 2 ↓, Ca 3 (AsO 3 ) 2 ↓, Ca 3 (AsO 4 ) 2 ↓、SiO2 2 ↓、CaHPO 4 2H 2 O↓ and CaS↓ are taken out, and the clear water after precipitation is sent to the combination tank (7), and 1 bag of soda ash 40kg is added in the combination tank, i.e. 40kg; sodium anthraquinone sulfonate 1kg; sodium metavanadate (V2O3) 0.5 kg; sodium methyl tartrate 0.2kg. Put the prepared combination liquid into the secondary washing...

Embodiment 2

[0054] Embodiment 2: the gas volume of yellow phosphorus tail gas is 500Nm 3 / h. Through the safety water seal, use the primary washing pump to pressurize to 0.3MPa, calculate according to the lime with a purity of 80%, add 15kg of lime, add the lime emulsion to the water level line, open the primary washing turbulence tower, and perform sufficient washing. The dust entrained by the yellow phosphorus tail gas is removed, and the washed sewage is put into the collection tank (5), and precipitated in the sedimentation tank (6), and the precipitated CaF 2 ↓, Ca 3 (AsO 3 ) 2 ↓, Ca 3 (AsO 4 ) 2 ↓、SiO2 2 ↓、CaHPO 4 2H 2 O↓ and CaS↓ are taken out, and the clear water after precipitation is sent to the combination tank (7), and 2 bags of soda ash 40kg packing are added in the combination tank, i.e. 80kg; sodium anthraquinone sulfonate 3kg; sodium metavanadate (V2O3) 1.5 kg; sodium methyl tartrate 0.6kg. Put the prepared combination liquid into the secondary washing tank (9) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com