Automatic monitoring system for down-hole central pumping room drainage

An automatic monitoring system and drainage system technology, applied in drainage, safety devices, mining equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0039] I. Overview,

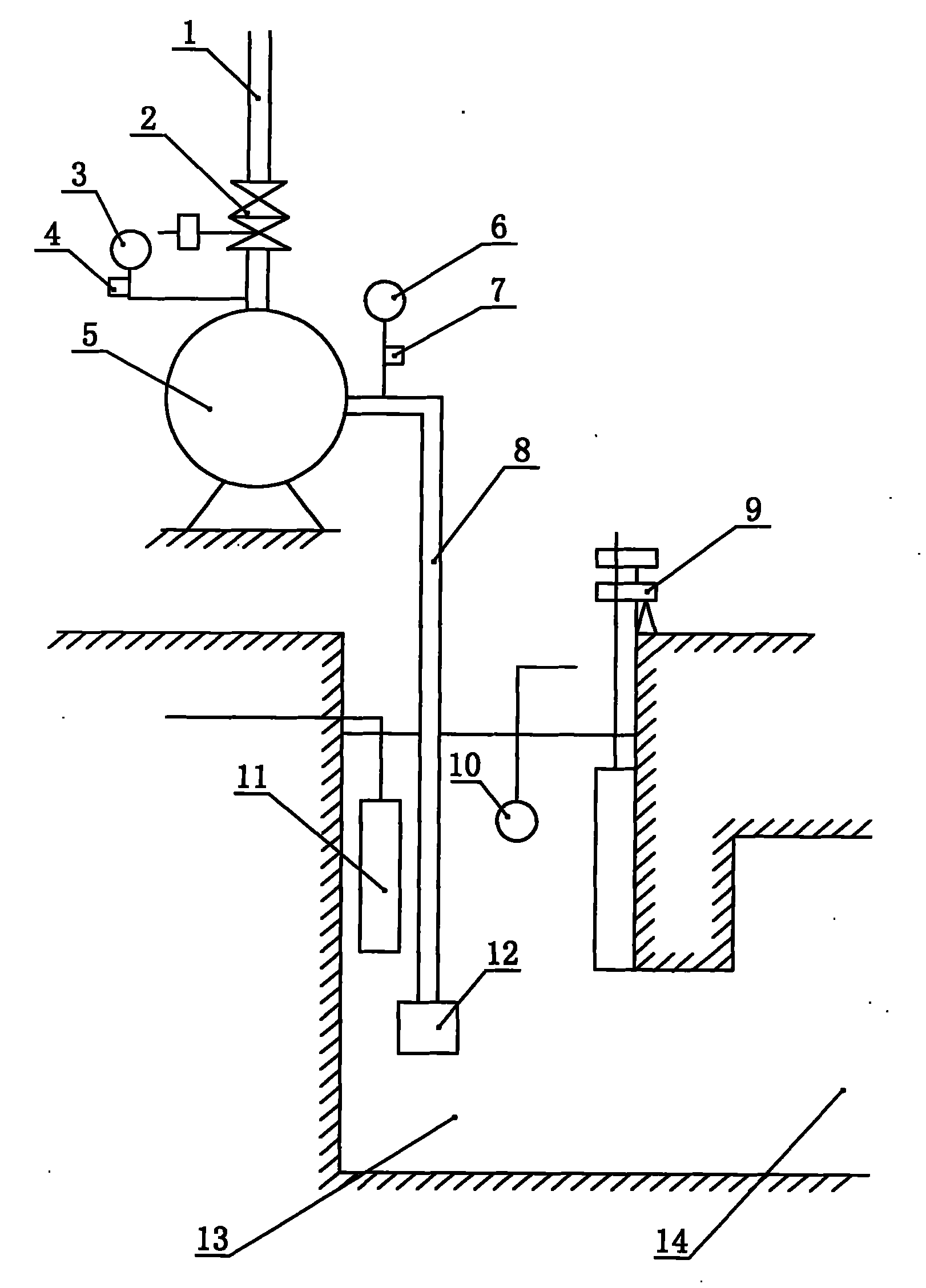

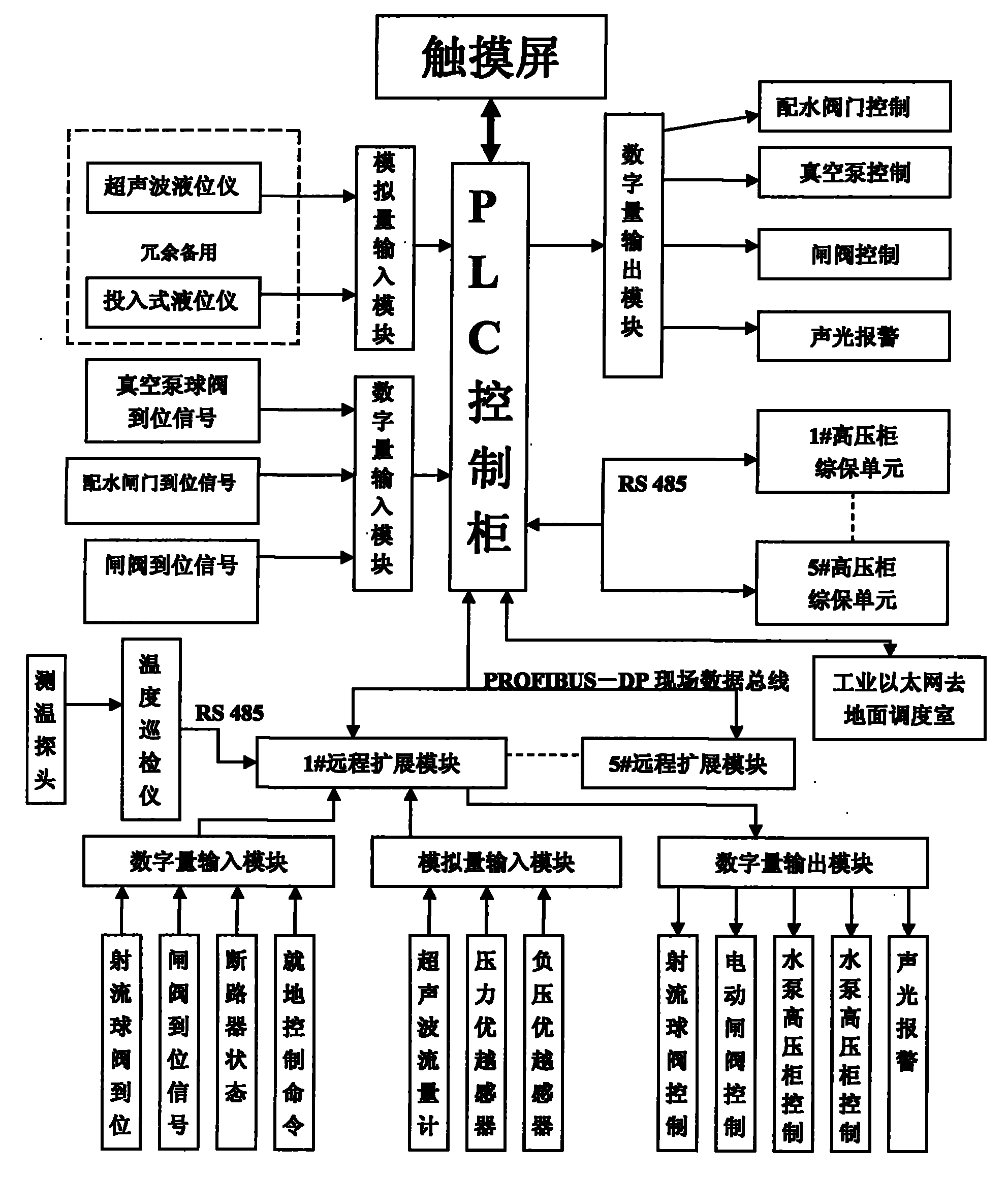

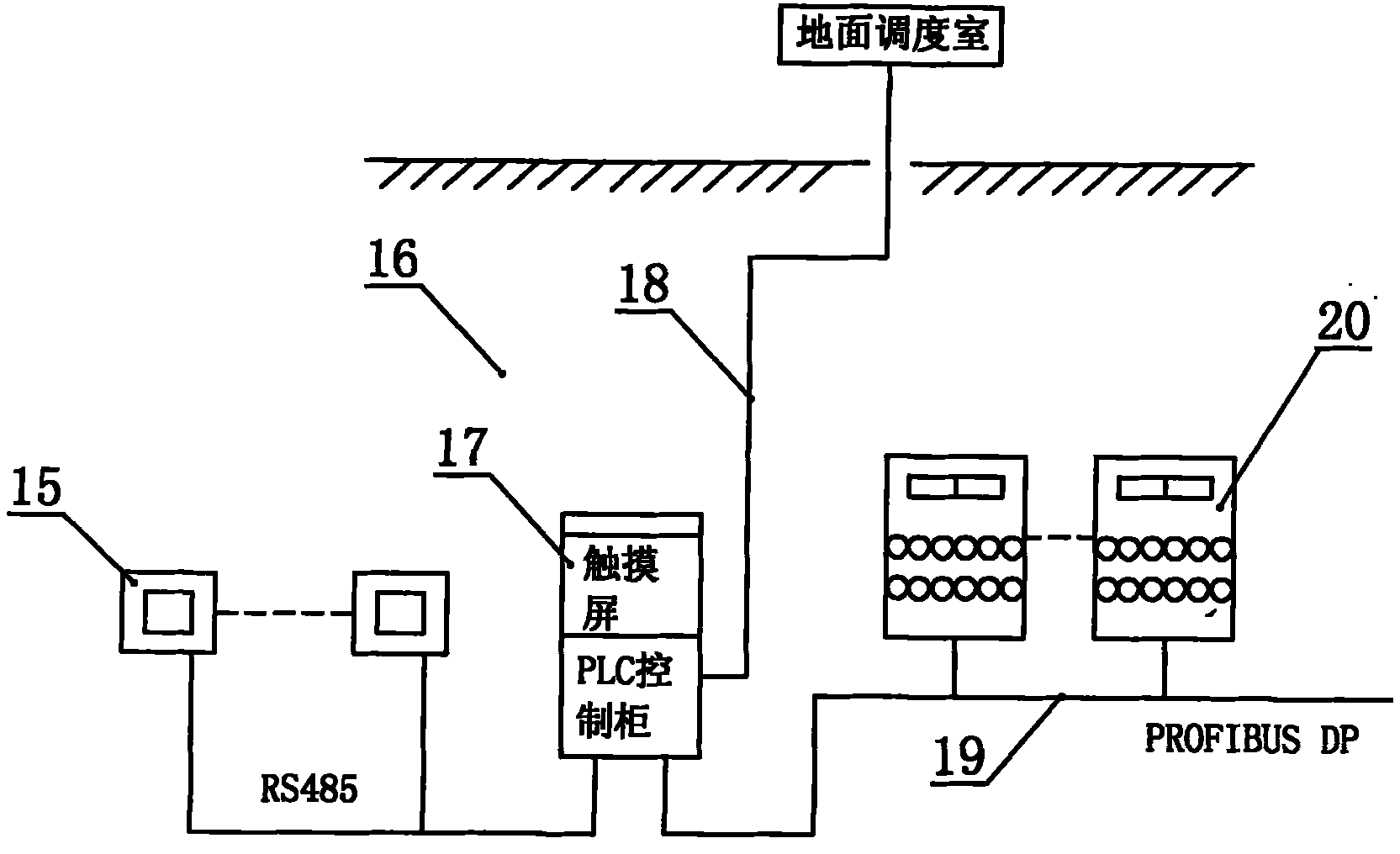

[0040] The mine drainage system is responsible for draining the underground water to the ground, and the underground central pump room generally drains the gushing water to the ground; whether the drainage system of the underground central pump room can operate reliably and effectively will be related to the drainage safety of the entire mine and even the safety of the mine. The drainage system of the underground central pump room generally consists of a water pump and a motor, the water pump starts the high-voltage switchgear, the water tank, the water suction well, the water pump vacuum device (vacuum pump or water jet vacuum device), three valves (gate valve, check valve, bottom valve; The gate valve and check valve are installed on the drainage pipeline, the bottom valve is installed at the end of the pump suction pipe), th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com